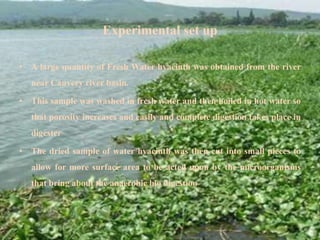

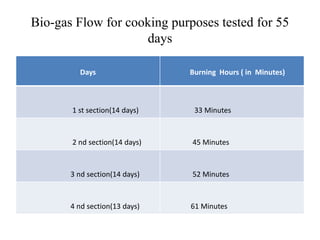

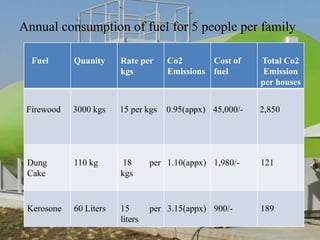

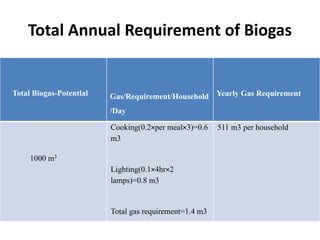

This document investigates utilizing water hyacinth for biogas generation. It describes setting up an experimental digester with chopped water hyacinth. Physical tests were conducted on the hyacinth and biogas production was monitored over 55 days, finding gas volumes increased over time. The biogas produced could potentially meet the annual fuel needs of 5 people and reduce their CO2 emissions compared to using firewood or dung cake. Future innovative uses of water hyacinth proposed include using it in bioremediation, effluent treatment, as a green pigment, and in manufacturing herbal tablets.