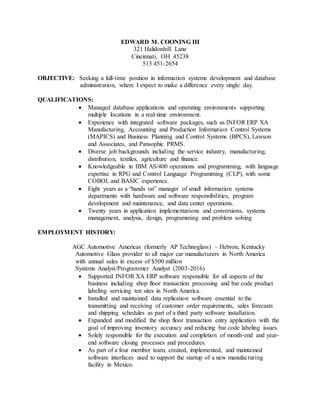

Edward M. Cooning III is seeking a full-time position in information systems development and database administration with over 20 years of experience. He has extensive experience managing database applications supporting multiple locations in real-time environments. His background includes experience with ERP software from INFOR, MAPICS, BPCS, and Lawson. He has worked in industries such as manufacturing, distribution, textiles, agriculture, and finance. Cooning has expertise in AS/400 operations and programming in RPG, CLP, COBOL, and BASIC. His experience includes roles as a systems analyst, programmer analyst, systems manager, and manager of information systems departments.