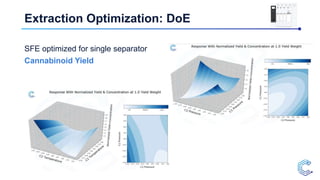

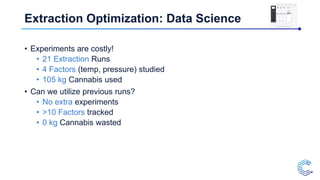

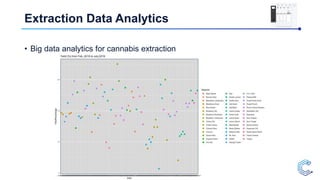

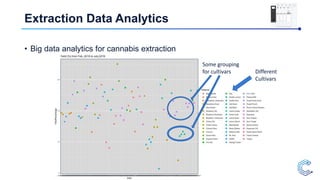

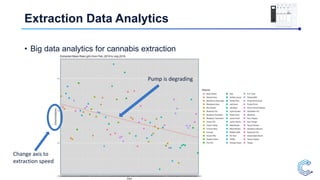

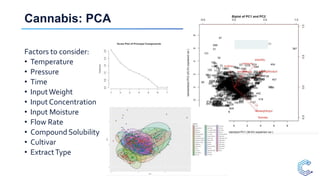

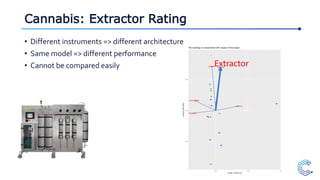

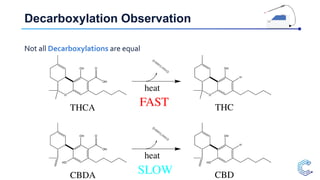

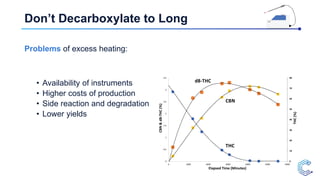

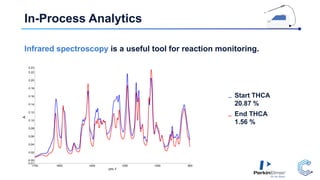

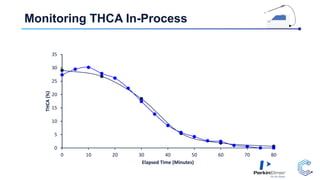

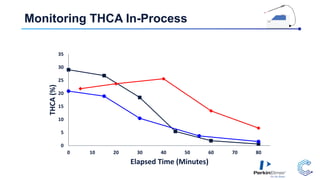

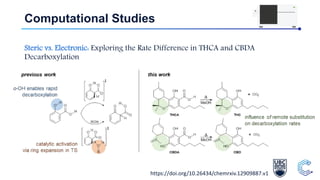

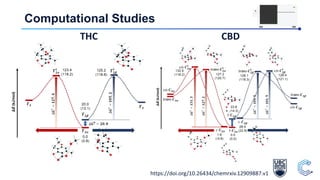

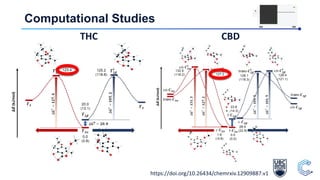

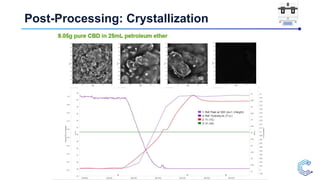

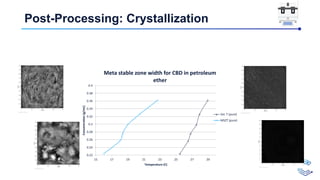

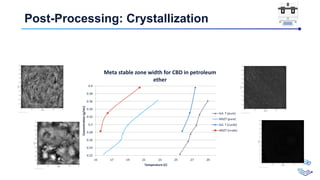

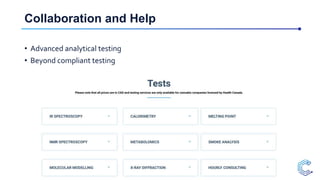

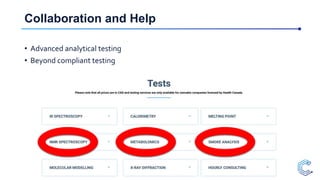

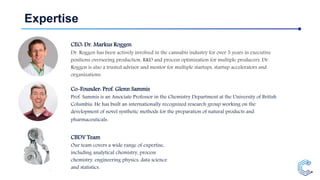

Complex Biotech Discovery Ventures (CBDV) focuses on cannabis production research in Vancouver, BC, emphasizing process design, optimization, and analytics through collaborations with various academic and industry partners. Key research areas include chemometrics, in-process analytics, and crystallization, with a goal to optimize extraction and decarboxylation processes while minimizing costs and wastage. Led by Dr. Markus Roggen and co-founder Prof. Glenn Sammis, the team combines expertise in analytical chemistry, data science, and engineering to advance cannabis production methodologies.