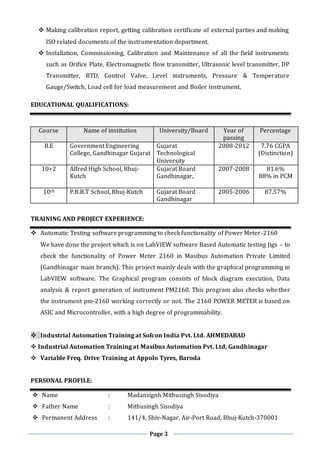

Mr. Madansingh Sisodiya is an electrical and instrumentation engineer with over 3 years of experience in project development and maintenance in the chemical industry. He has expertise in PLC programming, SCADA, field instruments including flow meters, temperature and pressure sensors, and motor and panel maintenance. Currently he works as an engineer at Ashapura Perfoclay Limited in Bhuj, Gujarat where he has experience with installation, commissioning and maintenance of electrical systems and instrumentation for plant expansions. He holds a B.E. in electrical engineering and has received training in industrial automation, variable frequency drives and automatic testing software.