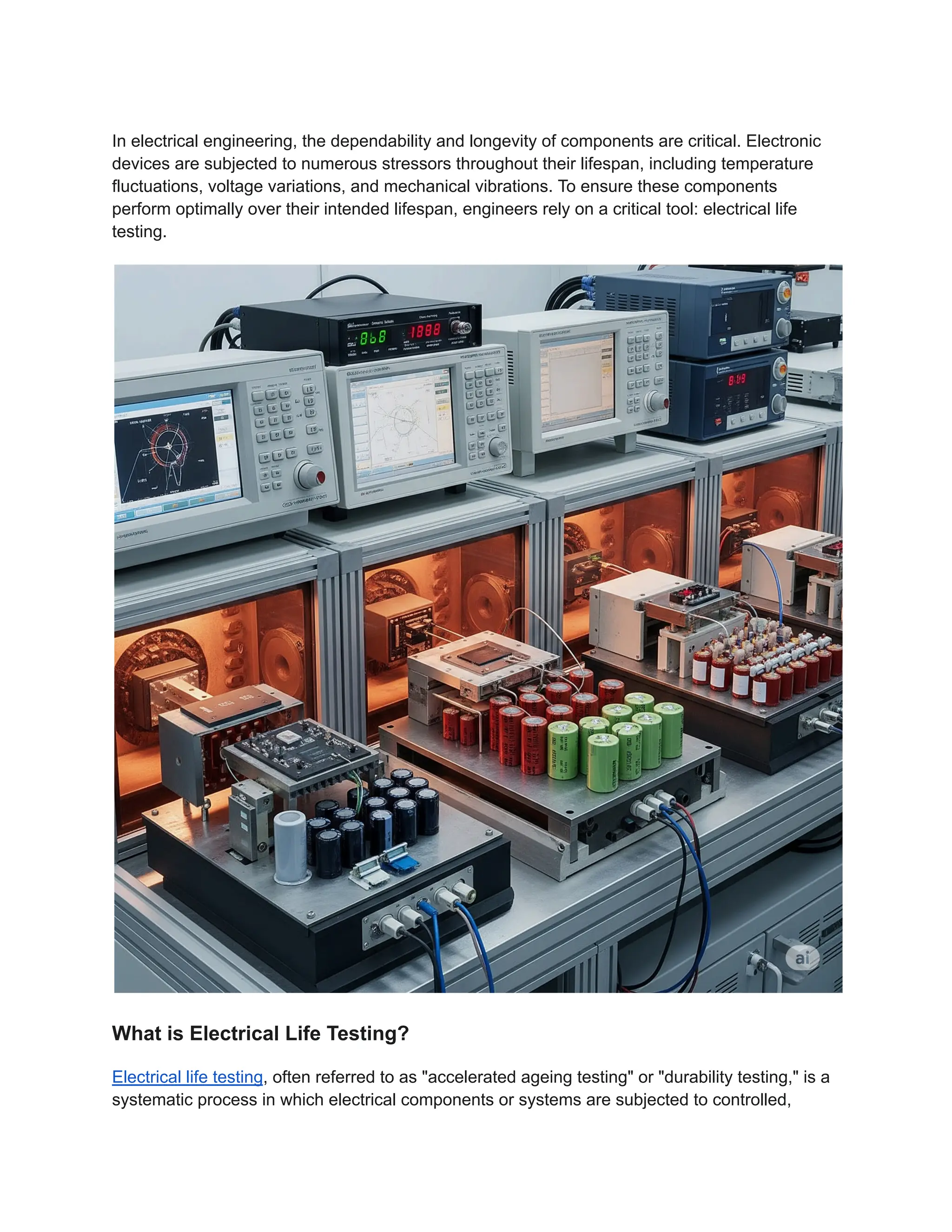

The document "Electrical Life Testing: Ensuring Long-Term Reliability" by CPL Group UK would likely focus on the company’s expertise in ensuring the safety, compliance, and longevity of electrical systems and equipment. CPL Group, known for its facilities management and electrical services in the UK, emphasizes maintaining safe and reliable electrical installations for commercial, industrial, and domestic clients. The document would probably detail their approach to electrical life testing, which involves assessing the durability and performance of electrical components over time to prevent failures, ensure compliance with regulations, and enhance operational efficiency.