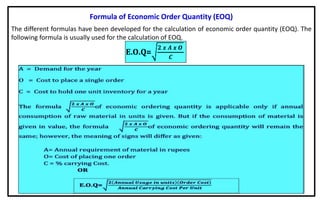

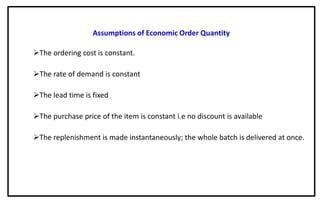

EOQ is the order quantity that minimizes total annual inventory costs by balancing ordering costs and carrying costs. Ordering costs include purchasing, receiving, and paperwork costs, while carrying costs include storage, insurance, and opportunity costs of capital tied up in inventory. The EOQ formula calculates the quantity that makes ordering and carrying costs equal to determine the optimal order size. Key assumptions are constant ordering costs, demand rate, lead time, purchase price, and instant replenishment.