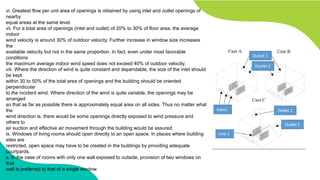

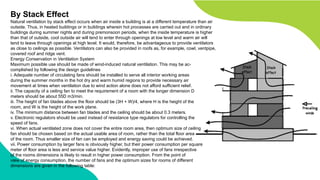

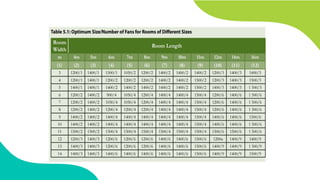

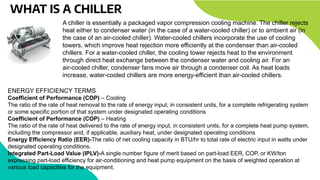

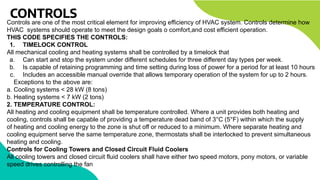

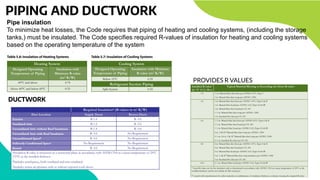

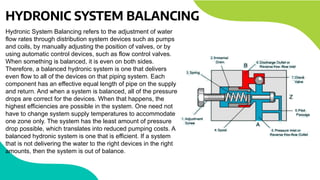

The document discusses heating, ventilation and air conditioning (HVAC) systems. It covers the basics of HVAC, including common components like compressors, condensers and evaporators. It also discusses different types of heating and cooling systems, focusing on central plant systems that use chilled water and direct expansion systems like split air conditioners. The document outlines mandatory code requirements for HVAC systems, including equipment efficiency standards, controls, balancing and economizers. It provides details on natural ventilation strategies using wind and stack effects, and guidelines for optimizing fan use for energy efficiency.