The document discusses drum manufacturing for steam boilers. It provides details on:

1) The functions of a boiler drum including steam-water separation, housing equipment for steam purification, and maintaining water level.

2) Standard drum specifications for different MW capacities including plate thickness, length, and weight.

3) Raw material suppliers and plate specifications.

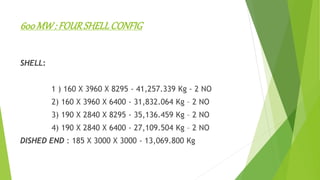

4) Configurations for different MW drums including number of shells and dimensions.

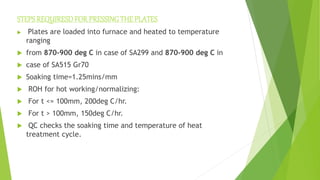

5) The hot forming process including plate heating temperatures and times.

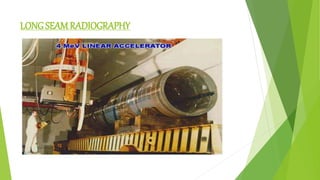

6) Quality checks and non-destructive testing of welds.

7) Other manufacturing steps like circumferential seam welding and hydrotesting.