The document describes the design of an afterburning low bypass turbofan engine to replace the General Electric J85 engine used on the Northrop Grumman T-38 Talon jet trainer. Initial values were obtained through parametric analysis in AEDsys ONX. A low bypass twin spool compressor with 3 fan stages and 5 high pressure compressor stages was selected. Additional components including the combustion chamber, turbines, and convergent-divergent nozzle were designed. The final engine design met the criteria of reduced thrust specific fuel consumption and weight while maintaining required thrust.

![10

• Expanded Technology Inc. Machine Shop

• Delta TechOps

• “Elements of Propulsion- Gas Turbines & Rockets” [1]

• “Aircraft Engine Design Second Edition” [2]

4 Results and Discussion

The use of parametric analysis for a real engine was the first process in designing a low bypass turbofan

engine. Once the values of the parametric analysis were finalized, AEDsys program was used to design

each component of the turbofan engine. In the following sections, 4.1 & 4.2, the parametric calculations

and the AEDsys design are describe in great detail. For reference, Figure 4.1 is a cross section of low

bypass turbofan engine with the station number locations.

Figure 4.1: Low Bypass Turbofan Station Numbering

4.1 Parametric Analysis

In order to compare the results of the given baseline turbojet engine to the newly developed low bypass

turbofan engine, a mathematical approach was initially considered. An analysis of a real engine required

a multitude of equations to be used. By applying the inputs of the turbojet with afterburner to a mixed-

flow low bypass turbofan with afterburner at each flight condition needed for the aircraft. Equations (1 –

45), listed below, can be used as an initial analysis for a mixed-flow low bypass turbofan with afterburner.

To simplify the process, the ONX program provided by AEDsys is used to do the parametric analysis

calculations. The results can be found in Appendix 12. After completing the analysis, a comparison

between both engines can be made. The fan pressure ratio and polytrophic efficiency of the fan were

initially assumed based on statistical data found in previous low bypass turbofan engines. Through

multiple iterations, the fan parameters can be finalized in order [2] to achieve the needed fuel

consumption and thrust.

Rc =

γc − 1

γc

cpc

(1)

Rt =

γt − 1

γt

cpt

(2)

RAB =

γAB − 1

γAB

cAB

(3)

a0 = √γcRcgcT0

(4)](https://image.slidesharecdn.com/231d0b88-dbe9-49bd-b399-a4bae3cc2de3-170201031715/85/DKA-867-Final-21-320.jpg)

ec γt⁄

} − (τc − 1)

τf − 1

(16)

τt = 1 −

1

ηm(1 + f)

τr

τλ

[τc − 1 + α(τf − 1)]

(17)

πt = τt

γt [(γt−1)et]⁄ (18)

𝑃𝑡16

𝑃𝑡6

=

𝜋 𝑓

𝜋 𝑐 𝜋 𝑏 𝜋 𝑡

(19)

𝑀16 = √

2

𝛾𝑐 − 1

{[

𝑃𝑡16

𝑃𝑡6

(1 +

𝛾𝑡 − 1

2

𝑀6

2

)

𝛾𝑡 (𝛾𝑡−1)⁄

]

(𝛾𝑐−1) 𝛾𝑐⁄

− 1}

(20)

𝛼′

=

𝛼

1 + 𝑓

(21)

𝑐 𝑝6𝐴 =

𝑐 𝑝𝑡 + 𝛼′

𝑐 𝑝𝑐

1 + 𝛼′

(22)](https://image.slidesharecdn.com/231d0b88-dbe9-49bd-b399-a4bae3cc2de3-170201031715/85/DKA-867-Final-22-320.jpg)

![12

𝑅6𝐴 =

𝑅𝑡 + 𝛼′

𝑅 𝑐

1 + 𝛼′

(23)

𝛾6𝐴 =

𝑐 𝑝6𝐴

𝑐 𝑝6𝐴 − 𝑅6𝐴

(24)

𝑇𝑡16

𝑇𝑡6

=

𝑇0 𝜏 𝑟 𝜏 𝑓

𝑇𝑡4 𝜏 𝑡

(25)

𝜏 𝑀 =

𝑐 𝑝𝑡

𝑐 𝑝6𝐴

1 + 𝛼′

(𝑐 𝑝𝑐 𝑐 𝑝𝑡)⁄ (𝑇𝑡16 𝑇𝑡6)⁄

1 + 𝛼′

(26)

𝜑(𝑀6, 𝛾6) =

𝑀6

2{1 + [(𝛾𝑡 − 1) 2⁄ ]𝑀6

2}

(1 + 𝛾𝑡 𝑀6

2

)2

(27)

𝜑(𝑀16, 𝛾16) =

𝑀16

2 {1 + [(𝛾𝑐 − 1) 2⁄ ]𝑀16

2 }

(1 + 𝛾𝑐 𝑀16

2

)2

(28)

𝛷 =

[

1 + 𝛼′

1

√𝜑(𝑀6, 𝛾6)

+ 𝛼′√

𝑅 𝑐 𝛾𝑡

𝑅𝑡 𝛾𝑐

𝑇𝑡16 𝑇𝑡6⁄

𝜑(𝑀16, 𝛾16)

]

2

𝑅6𝐴 𝛾𝑡

𝑅𝑡 𝛾6𝐴

𝜏 𝑀

(29)

𝑀6𝐴 = √

2𝛷

1 − 2𝛾6𝐴 𝛷 + √1 − 2(𝛾6𝐴 + 1)𝛷

(30)

𝐴16

𝐴6

=

𝛼′

√𝑇𝑡16 𝑇𝑡6⁄

𝑀16

𝑀6

√

𝛾𝑐 𝑅𝑡

𝛾𝑡 𝑅 𝑐

1 + [(𝛾𝑐 − 1) 2]⁄ 𝑀16

2

1 + [(𝛾𝑡 − 1) 2]⁄ 𝑀6

2

(31)

𝜋 𝑀 𝑖𝑑𝑒𝑎𝑙 =

(1 + 𝛼′

)√ 𝜏 𝑀

1 + 𝐴16 𝐴6⁄

𝑀𝐹𝑃(𝑀6, 𝛾𝑡, 𝑅𝑡)

𝑀𝐹𝑃(𝑀6𝐴, 𝛾6𝐴, 𝑅6𝐴)

(32)

𝜋 𝑀 = 𝜋 𝑀 𝑚𝑎𝑥 𝜋 𝑀 𝑖𝑑𝑒𝑎𝑙 (33)

𝑃𝑡9

𝑃9

=

𝑃0

𝑃9

𝜋 𝑟 𝜋 𝑑 𝜋 𝑐 𝜋 𝑏 𝜋 𝑡 𝜋 𝑀 𝜋 𝐴𝐵 𝜋 𝑛

(34)

Afterburner off:

𝑐 𝑝9 = 𝑐 𝑝6𝐴 𝑅9 = 𝑅6𝐴 𝛾9 = 𝛾6𝐴 𝑓𝐴𝐵 = 0](https://image.slidesharecdn.com/231d0b88-dbe9-49bd-b399-a4bae3cc2de3-170201031715/85/DKA-867-Final-23-320.jpg)

![13

𝑇9

𝑇0

=

𝑇𝑡4 𝜏 𝑡 𝜏 𝑀 𝑇0⁄

(𝑃𝑡9 𝑃9)⁄ (𝛾9−1) 𝛾9⁄

(35)

Afterburner on:

𝑐 𝑝9 = 𝑐 𝐴𝐵 𝑅9 = 𝑅 𝐴𝐵 𝛾9 = 𝛾 𝐴𝐵

𝑓𝐴𝐵 = (1 +

𝑓

1 + 𝛼

)

𝜏 𝜆𝐴𝐵 − (𝑐 𝑝6𝐴 𝑐 𝑝𝑡⁄ )𝜏 𝜆 𝜏 𝑡 𝜏 𝑀

𝜂 𝐴𝐵ℎ 𝑃𝑅 (𝑐 𝑝𝑐 𝑇0) − 𝜏 𝜆𝐴𝐵⁄ (36)

𝑇9

𝑇0

=

𝑇𝑡7 𝑇0⁄

(𝑃𝑡9 𝑃9)⁄ (𝛾9−1) 𝛾9⁄

(37)

Continue:

𝑀9 = √

2

𝛾9 − 1

[(

𝑃𝑡9

𝑃9

)

(𝛾9−1) 𝛾9⁄

− 1] (38)

𝑉9

𝑎0

= 𝑀9√

𝛾9 𝑅9 𝑇9

𝛾𝑐 𝑅 𝑐 𝑇0

(39)

𝑓𝑂 =

𝑓

1 + 𝛼

+ 𝑓𝐴𝐵

(40)

𝐹

𝑚̇ 0

=

𝑎0

𝑔𝑐

[(1 + 𝑓𝑂)

𝑉9

𝑎0

− 𝑀0 + (1 + 𝑓𝑂)

𝑅9

𝑅 𝑐

𝑇9 𝑇0⁄

𝑉9 𝑎0⁄

1 − 𝑃0 𝑃9⁄

𝛾𝑐

]

(41)

𝑆 =

𝑓𝑂

𝐹 𝑚̇ 0⁄

(42)

𝜂 𝑃 =

2𝑔𝑐 𝑉0(𝐹 𝑚̇ 0)⁄

𝑎0

2

[(1 + 𝑓𝑂)(𝑉9 𝑎0)⁄ 2

− 𝑀0

2

]

(43)

𝜂 𝑇 =

𝑎0

2

[(1 + 𝑓𝑂)(𝑉9 𝑎0)⁄ 2

− 𝑀0

2

]

2𝑔𝑐 𝑓𝑂ℎ 𝑃𝑅

(44)

𝜂 𝑂 = 𝜂 𝑃 𝜂 𝑇 (45)

4.2 AEDsys Software Analysis

When utilizing the AEDsys software provided, each individual stage must be calculated prior. By utilizing

the processes given by “Aircraft Engine Design” [1] book, the needed results can be found. Upon finding

these results, certain numbers can be placed in each stage of the AEDsys software. Once each stage is

filled in, the entire engine can be analyzed. The analysis will thus prove if the calculated results will provide

an engine suitable for the T-38 aircraft. Below are the given requirements and steps needed to accomplish

the task.](https://image.slidesharecdn.com/231d0b88-dbe9-49bd-b399-a4bae3cc2de3-170201031715/85/DKA-867-Final-24-320.jpg)

![14

4.2.1 Inlet

The INLET program of the AEDsys software is used to design a 2-D External Compression Inlet. Below in

Figure 4.2 an example of external compression inlet is given from Mattingly’s Aircraft Engine Design [2].

The inlet is designed for the desired maximum Mach velocity and flight condition. Before the inlet design

and calculations can be made the Inlet program asks for the following inputs: a chosen number of oblique

shocks, and their ramp angles (in degrees) relative to the Upstream Velocity Vector, the Free Stream Mach

Number, the Ratio of Specific Heats, the Corrected Mass Flow (lbm/s) or Area 0 (ft2

), and lastly the desired

Inlet Height-to-Width Ratio. Upon the completion of entering the inputs the user can press the Design

Calc button to return a sketch and dimensions of the design inlet. Additionally, the calculated performance

results across each oblique shock, an internal normal shock, and total change across the shocks is

returned.

Figure 4.2: External compression inlet

From the results a contour plot may be designed by pressing the Contours button. A window will emerge

asking the user to choose the desired x-axis and y-axis variables with the ability to select the variable

minimum and maximum values for each, the number of calculations to be made up to a max of 100, and

then a button to calculate the points for the plot contour data. Once these points are calculated the user

has a choice between having a standard black and white plot or a color plot to be made. Using the contour

plot, one can estimate the optimum values of either variable relative to the Inlet Total Pressures (Pts/Pt0)

described by the legend on the right side of the window. Refer to Appendix E for results of the INLET

program. Similarly refer to Appendix D: inlet inputs and requirements tables for Capture Area Estimations.](https://image.slidesharecdn.com/231d0b88-dbe9-49bd-b399-a4bae3cc2de3-170201031715/85/DKA-867-Final-25-320.jpg)

![15

The following equations, charts, and figures from the paper, “Preliminary Design of a 2D Supersonic Inlet

to Maximize Total Pressure Recover,” [3] are used as a reference to the Inlet program results:

Figure 4.3: Shock Pressure Recovery for Freestream Mach Number and Number of Oblique Shocks

Figure 4.4: Multi Shock Compression for Oswatisch Optimization

𝑀1 sin 𝜃1 = 𝑀2 sin 𝜃2 = ⋯ = 𝑀 𝑛−1 sin 𝜃 𝑛−1 (46)

Mach number and Turning Angle Calculations across each Oblique Shock (Ramp)

𝑀1

2

=

(𝛾 − 1)2

𝑀0

4

𝑠𝑖𝑛2

𝜃1 − 4(𝑀0

2

𝑠𝑖𝑛2

𝜃1 − 1)(𝛾𝑀0

2

𝑠𝑖𝑛2

𝜃1 + 1)

[2𝛾𝑀0

2

𝑠𝑖𝑛2 𝜃1 − (𝛾 + 1)][(𝛾 − 1)𝑀0

2

𝑠𝑖𝑛2 𝜃1 + 2] (47)](https://image.slidesharecdn.com/231d0b88-dbe9-49bd-b399-a4bae3cc2de3-170201031715/85/DKA-867-Final-26-320.jpg)

![16

tan 𝛿1 =

2𝑐𝑜𝑡𝜃1(𝑀0

2

𝑠𝑖𝑛2

𝜃1 − 1)

2 + 𝑀0

2

(𝛾 + 1 − 2𝑠𝑖𝑛2 𝜃1) (48)

𝑀2

2

=

(𝛾 − 1)2

𝑀1

4

𝑠𝑖𝑛2

𝜃2 − 4(𝑀1

2

𝑠𝑖𝑛2

𝜃2 − 1)(𝛾𝑀1

2

𝑠𝑖𝑛2

𝜃2 + 1)

[2𝛾𝑀1

2

𝑠𝑖𝑛2 𝜃2 − (𝛾 + 1)][(𝛾 − 1)𝑀1

2

𝑠𝑖𝑛2 𝜃2 + 2] (49)

tan 𝛿2 =

2𝑐𝑜𝑡𝜃2(𝑀1

2

𝑠𝑖𝑛2

𝜃2 − 1)

2 + 𝑀1

2

(𝛾 + 1 − 2𝑠𝑖𝑛2 𝜃2) (50)

Applying the optimum criteria from Eq. (4.46):

𝑀0 sin 𝜃1 = 𝑀1 sin 𝜃2 (51)

M2 is assumed to be equal to M3_up, and M3 _up will be a given input parameter, therefore M2

is known.

𝑀2 = 𝑀3_𝑢𝑝

(52)

Since M3_up is given, M3, the Mach number just after the normal shock, is calculated by the

normal shock equation:

𝑀3

2

=

(𝛾 − 1)𝑀3

2

_𝑢𝑝 + 2

2𝛾𝑀3

2

_𝑢𝑝 − (𝛾 − 1) (53)

In order to calculate M4, assume that M5 and hub-tip ratio h_t is given based on engine data.

Assuming the duct diameter is constant from 4 to 5, we have the following relation for the

airflow areas:

𝐴4

𝐴5

=

1

1 − ℎ_𝑡2 (54)

𝐴4

𝐴5

=

𝐴4

𝐴∗⁄

𝐴5

𝐴∗⁄ (55)

According to the Area-Mach number relation, we have:

(

𝐴5

𝐴∗

)

2

=

1

𝑀5

2 [

2

𝛾 − 1

(1 +

𝛾 − 1

2

𝑀5

2

)]

𝛾+1

𝛾−1

(56)

(

𝐴4

𝐴∗

)

2

=

1

𝑀4

2 [

2

𝛾 − 1

(1 +

𝛾 − 1

2

𝑀4

2

)]

𝛾+1

𝛾−1

(57)

With M5 known and using Eq. (54-58), the equation solving for M4 is derived.](https://image.slidesharecdn.com/231d0b88-dbe9-49bd-b399-a4bae3cc2de3-170201031715/85/DKA-867-Final-27-320.jpg)

![17

𝑀4 =

√

2

𝛾 + 1

𝛾+1

𝛾−1

(

𝐴5

𝐴∗)

2

−

2

𝛾 + 1

𝛾+1

𝛾−1

−1 (58)

For the 2 oblique shocks, the total pressure across each oblique shock is calculated as

the following:

𝑃𝑅𝑖 = [

(𝛾 + 1)𝑀𝑖−1

2

(sin 𝜃𝑖)2

(𝛾 − 1)𝑀𝑖−1

2 (sin 𝜃𝑖)2 + 2

]

𝛾

𝛾−1

[

(𝛾 + 1)

2𝛾𝑀𝑖−1

2 (sin 𝜃𝑖)2 − (𝛾 − 1)

]

1

𝛾−1

, 𝑖 = 1 − 2 (59)

The total pressure ratio across the normal shock is calculated by the following:

𝑃𝑅3 = [

(𝛾 + 1)𝑀3

2

_𝑢𝑝

(𝛾 − 1)𝑀3

2

𝑢𝑝

+ 2

]

𝛾

𝛾−1

[

(𝛾 − 1)

2𝛾𝑀3

2

𝑢𝑝

− (𝛾 − 1)

]

1

𝛾−1

(60)

From the subsonic diffuser, assume the total temperature is constant, then according to

the equation flow function, we have:

𝑃𝑅_𝑆𝑢𝑏 =

𝑃𝑡4

𝑃𝑡3

=

1

𝐴𝑅43

𝑊𝑓𝑓3

𝑊𝑓𝑓4 (61)

The flow function values Wff3 and Wff4 are determined by statics temperatures t3 and t4,

and the Mach numbers M3 and M4.

Based on Borda-Carnot loss equation, the following equation is derived with correction

factors:

𝑃𝑡4

𝑃𝑡3

= 1 − 𝐾 𝑀𝑡ℎ 𝐾𝑑 (1 −

1

𝐴𝑅43

)

2 𝛾

2 𝑀3

2

(1 +

𝛾 − 1

2 𝑀3

2

)

𝛾

𝛾−1 (62)

The coefficient KMth accounts for friction loss and Kd accounts for expansion loss. With

the values found, then the values of PR4 and AR43 are determined by solving Eq. (61) and

(62) simultaneously.

The total pressure recovery is then calculated as following:

𝑇𝑃𝑅 = ∏ 𝑃𝑅𝑖 × 𝑃𝑅_𝑠𝑢𝑏

3

𝑖=1

(63)](https://image.slidesharecdn.com/231d0b88-dbe9-49bd-b399-a4bae3cc2de3-170201031715/85/DKA-867-Final-28-320.jpg)

![18

Φ𝑖𝑛𝑙𝑒𝑡 =

(

𝐴0𝑖 𝑟𝑒𝑠

𝐴0 𝑟𝑒𝑞

− 1) {𝑀0 − (

2

𝛾 + 1 +

𝛾 − 1

𝛾 + 1 𝑀0

2

)

1

2

}

𝐹𝑔𝑐 (𝑚̇ 0 𝑎0)⁄

(64)

4.2.2 Fan & Compressor

One of the first steps in designing a gas turbine engine is to design the compressor. The turbine,

combustion chamber, and afterburner design are greatly determined by the outputs of the compressor.

Using the method describe in “Elements of Propulsion” [1], below is a list of the equations that were used

to calculate the initial values of each stage of the compressor. Each calculation had to be repeated for the

number of stages that were chosen for the compressor. The desired number of stages for a compressor

are determined by the designer preference, output required, and weight desired for the entire turbofan

engine. Certain inputs are initially assumed and later altered based on the designer’s preference in stage

loading, degree of reaction, stage efficiency, blade radius, blade solidity, and number of blades per stage.

These inputs include: M1, α1, α3, u2/u1, φcr, and φcs; to view typical initial guesses, see Table 11.2 located

in the Appendix D. The equations can also be used to determine the velocity triangles at each compressor

stage. The mass flow parameter can be calculated using the GASTAB program provided with the AEDSYS

software.

Air flow through an axial-flow compressor is naturally three-dimensional, which makes it extremely hard

to comprehend and analyze the flow. To simplify the design process, a two-dimensional flow field is used.

The sum of the two flow fields will give the total flow field. The two different coordinate systems are used

to describe the flow, Absolute (V = absolute velocity) is fixed to the compressor housing and the relative

(VR = relative velocity) is fixed to the rotating blades.

𝑇1 =

𝑇𝑡1

1 + (

𝛾 − 1

2 )𝑀1

2 (65)

𝑎1 = √ 𝛾𝑅𝑔𝑐 𝑇1

(66)

𝑉1 = 𝑀1 𝑎1 (67)

𝑢1 = 𝑉1 cos 𝛼1 (68)

𝜐1 = 𝑉1 sin 𝛼1 (69)

𝑃1 =

𝑃𝑡1

[1 + (

𝛾 − 1

2

) 𝑀1

2

]

𝛾

𝛾−1

(70)

MFP(M1)

𝐴1 =

𝑚̇ √ 𝑇𝑡1

𝑃𝑡1(cos 𝛼1)𝑀𝐹𝑃(𝑀1)

(71)](https://image.slidesharecdn.com/231d0b88-dbe9-49bd-b399-a4bae3cc2de3-170201031715/85/DKA-867-Final-29-320.jpg)

![23

cooled to a point that will allow the turbine to maintain stability. To begin the initial design, follow the

equations listed below.

Diffuser:

𝐴𝑅 =

𝐴3.2

𝐴3.1

(111)

𝜂 𝐷 =

𝜂 𝐷𝑚 𝐴𝑅2(1 − [𝐴3.1 𝐴 𝑚⁄ ]2) + 2(𝐴𝑅[𝐴3.1 𝐴 𝑚⁄ ] − 1)

𝐴𝑅2 − 1

(112)

(

𝛥𝑃𝑡

𝑞1

)

𝐷

= (1 −

1

𝐴𝑅2

)(1 − 𝜂 𝐷)

(113)

𝜋 𝐷 = 1 −

(∆𝑃𝑡 𝑞1⁄ ) 𝐷

1 + 2 𝛾𝑀3.1

2⁄

(114)

𝐴 𝑚 = 𝜂 𝐷𝑚(𝐴𝑅)𝐴3.1 (115)

𝐿 = 𝐻3.1 (

𝑟 𝑚3.1

𝑟 𝑚3.2

)

𝐴𝑅 − 1

2 tan 4.5𝑑𝑒𝑔

(116)

∆𝑥 = √𝐿2 − (𝑟3.1 − 𝑟3.2)2 (117)

Air Partitioning:

𝜑4 =

𝑚̇ 𝑓𝑀𝐵

𝑓𝑠𝑡 𝑚̇ 3.1

(118)

∆𝑇 𝑚𝑎𝑥 =

𝑇𝑡4 − 𝑇3.1

𝜑4

(119)

𝜑 𝑆𝑍 =

𝑇𝑔 − 𝑇3.1

∆𝑇 𝑚𝑎𝑥

(120)

𝜑 𝑃𝑍 =

𝜑 𝑆𝑍

𝜀 𝑃𝑍

(121)

𝜇 𝑃𝑍 =

𝜑4

𝜑 𝑃𝑍

(122)

𝜇 𝑆𝑍 =

𝜑4

𝜑 𝑆𝑍

−

𝜑4

𝜑 𝑃𝑍

(123)

𝑇𝑔 = 𝑇𝑡3.1 + 𝜑 𝑃𝑍 𝜀 𝑃𝑍∆𝑇 𝑚𝑎𝑥 (124)

𝛷 =

𝑇𝑔 − 𝑇 𝑚

𝑇𝑔 − 𝑇3.1

(125)](https://image.slidesharecdn.com/231d0b88-dbe9-49bd-b399-a4bae3cc2de3-170201031715/85/DKA-867-Final-34-320.jpg)

![24

For Film Cooling:

𝜇 𝑐 =

1

6

(

𝑇𝑔 − 𝑇 𝑚

𝑇 𝑚 − 𝑇3.1

)

(126)

For Transpiration or Effusion Cooling:

𝜇 𝑐 =

1

25

(

𝑇𝑔 − 𝑇 𝑚

𝑇 𝑚 − 𝑇3.1

)

(127)

𝜇 𝐷𝑍 = 1 − (𝜇 𝑃𝑍 + 𝜇 𝑆𝑍 + 𝜇 𝑐) (128)

Dome and Liner:

(

∆𝑃𝑡

𝑞 𝑟

)

𝑀𝐵

=

𝑃𝑡3.2 − 𝑃𝑡4

𝑃𝑡3.2 − 𝑃3.2

(129)

𝑚̇ 𝐴

𝑚̇ 𝑟

= 𝜇 𝑆𝑍 + 𝜇 𝐷𝑍

(130)

𝛼 𝑜𝑝𝑡 = 1 − (

𝑚̇ 𝐴

𝑚̇ 𝑟

)

2 3⁄

(

∆𝑃𝑡

𝑞 𝑟

)

𝑀𝐵

−1 3⁄ (131)

𝐻𝐿 = 𝛼 𝑜𝑝𝑡 𝐻𝑟 (132)

Total Pressure Loss:

𝜏 𝑃𝑍 =

𝑇𝑔

𝑇𝑡3.2

(133)

(

∆𝑃𝑡

𝑞 𝑟

)

𝑚𝑖𝑛

= (

𝜇 𝑃𝑍

𝛼 𝑜𝑝𝑡

)

2

𝜏 𝑃𝑍(2𝜏 𝑃𝑍 − 1)

(134)

Primary Zone:

𝑉𝑗 = 𝑈𝑟√(

∆𝑃𝑡

𝑞 𝑟

)

𝑀𝐵

(135)

𝐶 𝐷90° = {

0.64 𝑓𝑜𝑟 𝑝𝑙𝑎𝑖𝑛 ℎ𝑜𝑙𝑒𝑠

0.81 𝑓𝑜𝑟 𝑝𝑙𝑢𝑛𝑔𝑒𝑑 ℎ𝑜𝑙𝑒𝑠

(136)

𝑟𝑡 = √ 𝑟ℎ

2

+

𝑚̇ 𝑃𝑍 − 3𝑚̇ 𝑓𝑀𝐵

𝑁𝑛𝑜𝑧 𝜋𝐶 𝐷90° cos 𝛼 𝑠𝑤

(

𝐴 𝑟

𝑚̇ 𝑟

) (

∆𝑃𝑡

𝑞 𝑟

)

𝑀𝐵

−1 2⁄ (137)

𝑆′

=

2

3

tan 𝛼 𝑠𝑤 [

1 − (𝑟ℎ 𝑟𝑡⁄ )3

1 − (𝑟ℎ 𝑟𝑡⁄ )2

]

(138)

𝐴 𝑆𝑊 = 𝜋(𝑟𝑡

2

− 𝑟ℎ

2

) (139)

𝐿 𝑃𝑍 = 2𝑆′

𝑟𝑡 (140)](https://image.slidesharecdn.com/231d0b88-dbe9-49bd-b399-a4bae3cc2de3-170201031715/85/DKA-867-Final-35-320.jpg)

![26

𝑑ℎ =

𝑑𝑗

√𝐶 𝐷90° sin 𝜃

(155)

𝑁ℎ𝐷𝑍 = 𝜇 𝐷𝑍 (

4𝐴 𝑟

𝜋𝑑𝑗

2)

𝑈𝑟

𝑉𝑗

(156)

𝐿 𝐷𝑍 = 1.5𝐻𝐿 (157)

Total Length:

𝐿 𝐿 = 𝐿 𝑃𝑍 + 𝐿 𝑆𝑍 + 𝐿 𝐷𝑍 (158)

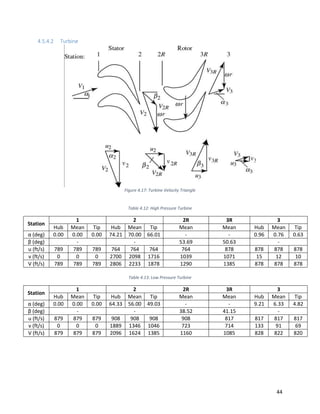

4.2.4 Turbine

Upon completing the initial calculations for the compressor, the turbine calculations can be started. Based

on the number of high pressure and low pressure stages of both the fan and compressor will determine

the number of stages in the turbine. The high pressure turbine(s) will power the high pressure compressor

stages, the low pressure turbine(s) will power both the low pressure compressor and fan stages. The

decision on the number of stages for both high and low pressure turbines will be based upon weight,

designer preference, stage loading, and power needed to drive the compressor. Once the designer

achieves desired results, the turbine calculations will be completed. Below is a list of equations (159 - 192)

for calculating the mean-radius stage for stator and rotor flow with losses. The equations can also be used

to determine the velocity triangles at each turbine stage. Certain inputs are initially assumed and later

altered based on the designer’s preference in stage loading, degree of reaction, stage efficiency, blade

radius, blade solidity, and number of blades per stage. These inputs include: M2, α1, α3, u3/u2, φt stator, and

φt rotor; to view typical initial guesses, see Table 11.5 located in the Appendix. It is important to keep in

mind that M2 must be supersonic at the first turbine stage in order to obtained choked flow but should

not cause M3 to be greater than 0.9. It is also important to note that a desirable multistage design would

have the total temperature difference distributed evenly among each stage. Within each stage, the total

temperature at station two will equal that of station one (i.e. Tt1 = Tt2). It can also be seen that the stage

loading should remain between 1.4 and 2 for modern aircraft engines. For simplicity of design, α1 will

remain the same throughout each stage of the turbine.

𝑇1 =

𝑇𝑡1

1 + [(𝛾 − 1)/2]𝑀1

2

(159)

𝑉1 = √

2𝑔𝑐 𝑐 𝑝 𝑇𝑡1

1 + 2 [(𝛾 − 1)𝑀1

2]⁄

(160)

𝑢1 = 𝑉1 cos 𝛼1 (161)

𝑣1 = 𝑉1 sin 𝛼1 (162)

𝑇2 =

𝑇𝑡2

1 + [(𝛾 − 1) 2⁄ ]𝑀2

2

(163)](https://image.slidesharecdn.com/231d0b88-dbe9-49bd-b399-a4bae3cc2de3-170201031715/85/DKA-867-Final-37-320.jpg)

![27

𝑉2 = √

2𝑔𝑐 𝑐 𝑝 𝑇𝑡2

1 + 2 [(𝛾 − 1)𝑀2

2]⁄

(164)

𝜓 =

𝑔𝑐 𝑐 𝑝(𝑇𝑡1 − 𝑇𝑡3)

(𝜔𝑟)2

(165)

𝛼2 = sin−1

(𝜓

𝜔𝑟

𝑉2

) − (

𝑢3

𝑢2

tan 𝛼3) √1 + (

𝑢3

𝑢2

tan 𝛼3)

2

− (𝜓

𝜔𝑟

𝑉2

)

2

1 + (

𝑢3

𝑢2

tan 𝛼3)

2

(166)

𝑢2 = 𝑉2 cos 𝛼2 (167)

𝑣2 = 𝑉2 sin 𝛼2 (168)

𝛷 =

𝑢2

𝜔𝑟

(169)

𝑉3 =

𝑢3

𝑢2

cos 𝛼2

cos 𝛼3

(170)

𝑢3 = 𝑉3 cos 𝛼3 (171)

𝑣3 = 𝑉3 sin 𝛼3 (172)

°𝑅𝑡 = 1 −

1

2𝜓

(

𝑉2

𝜔𝑟

)

2

[1 − (

𝑢3 cos 𝛼2

𝑢2 cos 𝛼3

)

2

]

(173)

𝑇3 = 𝑇2 − °𝑅𝑡(𝑇𝑡1 − 𝑇𝑡3) (174)

𝑀3 = 𝑀2

𝑉3

𝑉2

√

𝑇2

𝑇3

(175)

𝑀2𝑅 = 𝑀2√cos2 𝛼2 + (sin 𝛼2 −

𝜔𝑟

𝑉2

)

2

(176)

𝑀3𝑅 = 𝑀3√cos2 𝛼3 + (sin 𝛼3 −

𝜔𝑟

𝑉3

)

2

(177)

𝑇𝑡3𝑅 = 𝑇𝑡2𝑅 = 𝑇𝑡3 +

𝑉3

2

2𝑔𝑐 𝑐 𝑝

[cos2

𝛼3 + (sin 𝛼3 +

𝜔𝑟

𝑉3

)

2

− 1]

(178)](https://image.slidesharecdn.com/231d0b88-dbe9-49bd-b399-a4bae3cc2de3-170201031715/85/DKA-867-Final-38-320.jpg)

![28

𝜏 𝑠 =

𝑇𝑡3

𝑇𝑡1

(179)

𝑍𝑠 𝑐 𝑥

𝑠

= (2 cos2

𝛼2) (tan 𝛼1 +

𝑢2

𝑢1

tan 𝛼2) (

𝑢1

𝑢2

)

2 (180)

𝛽2 = tan−1

𝑣2 − 𝜔𝑟

𝑢2

(181)

𝛽3 = tan−1

𝑣3 + 𝜔𝑟

𝑢3

(182)

𝑍 𝑟 𝑐 𝑥

𝑠

= (2 cos2

𝛽3) (tan 𝛽2 +

𝑢3

𝑢2

tan 𝛽3)(

𝑢2

𝑢3

)

2 (183)

𝑃1 = 𝑃𝑡1 (

𝑇1

𝑇𝑡1

)

𝛾 (𝛾−1)⁄ (184)

𝑃𝑡2 =

𝑃𝑡1

1 + 𝜑 𝑡 𝑠𝑡𝑎𝑡𝑜𝑟[1 − (𝑇2 𝑇𝑡2⁄ ) 𝛾 (𝛾−1)⁄ ]

(185)

𝑃2 = 𝑃𝑡2 (

𝑇2

𝑇𝑡2

)

𝛾 (𝛾−1)⁄ (186)

𝑃𝑡2𝑅 = 𝑃2 (

𝑇𝑡2𝑅

𝑇2

)

𝛾 (𝛾−1)⁄ (187)

𝑃𝑡3𝑅 =

𝑃𝑡2𝑅

1 + 𝜑 𝑡 𝑟𝑜𝑡𝑜𝑟[1 − (𝑇3 𝑇𝑡3𝑅⁄ ) 𝛾 (𝛾−1)⁄ ]

d

(188)

𝑃3 = 𝑃𝑡3𝑅 (

𝑇3

𝑇𝑡3𝑅

)

𝛾 (𝛾−1)⁄ (189)

𝑃𝑡3 = 𝑃3 (

𝑇𝑡3

𝑇3

)

𝛾 (𝛾−1)⁄ (190)

𝜋 𝑠 =

𝑃𝑡3

𝑃𝑡1

(191)

𝜂 𝑠 =

1 − 𝜏 𝑠

1 − 𝜋 𝑠

(𝛾−1) 𝛾⁄

(192)

After completing the calculations for each desired stage; the flow annulus area, radii, and number of

blades can be calculated for each stator and rotor. Below is a list of equations (193 - 211) that allow for

completion of the calculation process. Upon completing the calculations, the values found can be placed](https://image.slidesharecdn.com/231d0b88-dbe9-49bd-b399-a4bae3cc2de3-170201031715/85/DKA-867-Final-39-320.jpg)

![34

𝐶𝑓𝑔 =

𝐶𝑓𝑔 𝑝𝑒𝑎𝑘 𝑚̇ 7 𝑉9𝑖 𝑔𝑐⁄ + (𝑃9𝑖 − 𝑃0)𝐴9

𝑚̇ 7 𝑉𝑠 𝑔𝑐⁄

(220)

𝐹𝑔 = 𝐶𝑓𝑔 𝑝𝑒𝑎𝑘 𝑚̇ 7 𝑉9𝑖 𝑔𝑐⁄ + (𝑃9𝑖 − 𝑃0)𝐴9 (221)

𝐶 𝑉 =

𝑉9

𝑉9𝑖

= √

1 − (𝑃9 𝑃𝑡9⁄ )(𝛾−1) 𝛾⁄

1 − (𝑃9𝑖 𝑃𝑡8⁄ )(𝛾−1) 𝛾⁄

(222)

𝑃9

𝑃𝑡9

= {1 − 𝐶 𝑉

2

[1 − (

𝑃9𝑖

𝑃𝑡8

)

(𝛾−1) 𝛾⁄

]}

𝛾 (𝛾−1)⁄

(223)

𝜋 𝑛 =

𝑃𝑡9

𝑃𝑡8

= 𝐶 𝐷

𝐴 𝐴∗⁄ |9

𝐴9 𝐴8⁄

(224)

4.3 Weight Calculation Method

Due to the fact that the DKA-867 is in the preliminary stage of design, a preliminary weight estimation

was made for both the engine with and without a tailpipe. For a more in depth look as to what the exact

weight of the engine will be based on dimensioning and material choice, a CAD model will need to be

made. The CAD model will allow for a material selection for each individualized component of the engine.

Once labeled and completed, the weight of each component may be found. Although, a CAD model will

only give a valid comparison to an actual low-bypass turbofan engine. The only way to truly know the

actual weight of the engine is to create a prototype model that uses equivalent density materials or the

same materials stated below in the materials section of this report. For the case of the DKA-867, the

preliminary weight calculation can be made via equation (225) found below. This will be used to find the

weight of the engine with the afterburning section. To find the weight without afterburner, comparisons

of afterburners with similar dimensions of the one used in the DKA-867 low-bypass turbofan with

afterburner were used. Using an average of the afterburner weights found, the weight was then

subtracted from the weight found using the equation below. It can be seen that both the thrust and Mach

number used in the equation are the maximum allotted by the engine.

𝑊 = 0.063𝑇1.1

𝑀0.25

𝑒(−0.81 𝐵𝑃𝑅) (225)

4.4 Mission Analysis

The analysis of each mission needed for the Northrop Grumman T-38 Talon was determined using the

AEDsys software provided by “Aircraft Engine Design Second Edition” [2]. Upon completing the ONX

parametric analysis provided, a document will be saved with the results. Using these results, a mission

analysis can be done. To begin the analysis, the completed parametric analysis must be uploaded to the

AEDsys main program software. Once uploaded, the aircraft and engine type must be chosen based on

the needs of the designer. This will allow for a more realistic output when selecting the needed mission.

These can be selected by going to the ‘Aircraft Drag’ and ‘Engine’ tabs found on the task bar. To state how

many engines will be used in flight, the ‘Cycle Deck’ button can be opened under the ‘Engine’ tab. Next,

the ‘Mission’ button should be clicked, which will open a second screen that is used to determine a given

operation.](https://image.slidesharecdn.com/231d0b88-dbe9-49bd-b399-a4bae3cc2de3-170201031715/85/DKA-867-Final-45-320.jpg)

![45

5 Material Selections

Below is a list of materials that will be used in the design of the DKA-867 engine. The materials have been

found via the “Aircraft Engine Design Second Edition” [2] in the Reference section. Each has a brief

description of the capabilities along with the properties and components associated as they relate to

aircraft engines. Most of the materials have been recently developed and have proved to excel in the

components listed within the sections. It is highly advised for the engine developer to use these materials

when finalizing the design of the DKA-867.

5.1 Aluminum 2124 Alloy (ρ = 5.29 slug/ft3

)

This is one of a series of premium aluminum alloys that were developed as a result of studies into the

micro mechanisms of fracture in high-strength aluminum compositions. Normally, the alloy is produced

in a plate with a thickness ranging up to six inches. It can be seen in Figure 5.1 below the traditional yield

and ultimate tensile strength data for Aluminum 2124. The figure will allow for a non-conservative design

to be considered because of the fact that the part could undergo permanent deformation during the

exposure time.

Figure 5.1: Effect of Temperature and Exposure Time on Tensile Properties

It is actually preferable to base designs on creep and creep-rupture data. The values for these can be

determined by using Figure 5.2. For common practice, an allowance of less than 1% creep during the life

of the part. As seen in the figure, Al 2124 is seldom used above 400˚F. From the figure, it should be noted

that reductions will be made to results because of the cyclic stress, uncertainties in load calculations,

property variations, and safety margins. Based on the properties seen in the figures and recently stated,

the inlet and nacelle will be using Al 2124.](https://image.slidesharecdn.com/231d0b88-dbe9-49bd-b399-a4bae3cc2de3-170201031715/85/DKA-867-Final-56-320.jpg)

![52

7 References

[1] J. D. Mattingly, Elements of Propulsion: Gas Turbines and Rockets, 1st Edition ed., J. A. Schetz, Ed.,

Reston, Virginia: AmericanInstituteof Aeronauticsand Astronautics,Inc., 2006.

[2] J. D. Mattingly, Aircraft Engine Design, 2nd Edition ed., J. S. Przemieniecki, Ed., Reston , VA: American

Institute of Aeronautics and Astronautics , 2002.

[3] H. R. &. D. Mavris, "Preliminary Design of a 2D SUpersonic Inlet to Maximize Total Pressure Recovery".

[4] J. L. Kerrebrock, Aircraft Engines and Gas Turbines, Massachusetts: The Alpine Press Inc. , 1977.

[5] C. W. Smith, Aircraft Gas Turbines, New York : John Wiley & Sons , 1956.

[6] FAA, "14 CFR Parts Applicable to Engines & Propellers," 22 March 2016. [Online]. Available:

https://www.faa.gov/aircraft/air_cert/design_approvals/engine_prop/engine_prop_regs/regs/ .

[Accessed 10 April 2016].](https://image.slidesharecdn.com/231d0b88-dbe9-49bd-b399-a4bae3cc2de3-170201031715/85/DKA-867-Final-63-320.jpg)

![55

10 Appendix C: Reflections

David Byrd:

This project has been the most challenging yet interesting task of my college career. I have always had a

love for engines and trying to make them more powerful. When AIAA posed a competition to design a

low-bypass turbofan engine using a baseline turbojet engine, I knew this was the project for me.

Fortunately, I found two other people with the same passion for air, fuel, and power. The three of us set

out to design the best low bypass engine we could as well as furthering our understanding of gas turbine

engine.

Upon starting the project, I decided that I would take on the responsibility of designing the compressor

and the afterburner. Little did I know how complex and vital the compressor was to the entire engine.

With the use of “Aircraft Engine Design Second Edition” [2] and “Elements of Propulsions: Gas Turbines

and Rockets” [1] books, I was able to increase my knowledge of the in-depth calculations for each stage

of the compressor. Using the process found in both books, I generated an Excel spreadsheet for each stage

of the compressor. This task turned into a considerable greater undertaking. Even though the Excel

spreadsheet did not work the way anticipated, it did increase my understanding of the relationship with

the values in the compressor. I took most of the values found in the Excel spreadsheet and input the into

COMPR program. The output data allowed me to double check my initial calculations and provided other

critical data for the compressor. After main iterations of the Excel spreadsheet and the COMPR program,

the compressor was finally completed.

One of the major disadvantages of designing the afterburner, was the lack of useful resources. “Aircraft

Engine Design Second Edition” [2] used a combination of ONX, GASTAB, AFTRBRN program to design the

afterburner. I initial started an Excel Spreadsheet, but reverted to the process describe in “Aircraft Engine

Design Second Edition” [2] book due to absence of information. However, the process in the book was

not the easiest to follow, but did produce excellent results. This Project has been a great challenge to me

while sheading knowledge of the complexity of a gas turbine engine. I would like to thank Dr. Adeel Khalid

for his time teaching and a growing my love of the aerospace engineering.

Kristian Lien:

Upon beginning the engine design project, I knew it would be a great challenge. It soon became one of

the hardest things I had done in school but also my greatest success. Upon taking the Aircraft Propulsion

class, I knew that my calling would be to design engines for a living. To challenge that goal, my group and

I decided to design a propulsive system for our Aeronautics Senior Design Project. Luckily, AIAA had posed

a competition to design a low-bypass turbofan engine using a baseline turbojet engine. This helped in the

ease of knowing what to expect for results as well as comparison purposes. In beginning the project, each

component had to be designated to each group member.

I had decided to design the turbine as well as the combustion chamber. Initially, I knew that the design of

both would be quite perplexing. To obtain more knowledge about each individual system, much research

and reading was done. By using both the “Aircraft Engine Design Second Edition” [2] and “Elements of

Propulsions: Gas Turbines and Rockets” [1] books, much new knowledge was obtained on either subject.

To begin, the turbine had to be developed. Using the equations found in each book, an Excel spreadsheet

was created. The results of the spreadsheet created little success but helped with an understanding of

how each input value could determine the resulting flow through the turbine. After weeks of](https://image.slidesharecdn.com/231d0b88-dbe9-49bd-b399-a4bae3cc2de3-170201031715/85/DKA-867-Final-66-320.jpg)