Diseno a corte

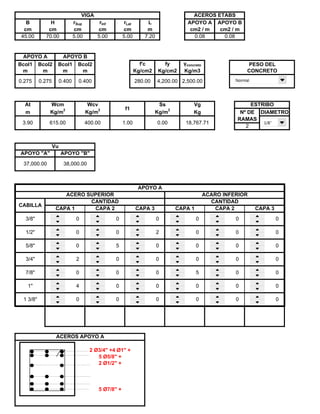

- 1. APOYO A 0 0 0 0 0 CANTIDAD ACERO SUPERIOR CAPA 1 0 0 ACARO INFERIOR 2 CAPA 2 CAPA 3 0 0 0 0 0 0 0 0 0 0 0 0 0 0 CAPA 3 CANTIDAD 0 00 CAPA 1 0 0 0 0 0 00 0 0 0 5 0 5 0 0 0 0 0 0 ACEROS ETABS m m m cm2 / m 0 0 0 Nº DE DIAMETRO CABILLA CAPA 2 APOYO A APOYO B 0 fyBcol2 Bcol1 Bcol2 APOYO A APOYO B cm m m 37,000.00 B H rSup rInf rLat L cm2 / m RAMAS Kg/cm2 Kg/cm2 APOYO "B" Vu cm cm cm cm 0.08 0.0845.00 70.00 5.00 5.00 5.00 7.20 2 3/8" 0 APOYO "A" γconcreto Kg/m3 Bcol1 ESTRIBO f'c 1/2" 0 5/8" 0 3/4" 2 1 3/8" 0 7/8" 0 1" 4 0 5 Ø7/8" + ACEROS APOYO A 2 Ø3/4" +4 Ø1" + 5 Ø5/8" + 2 Ø1/2" + Ss m Kg/m2 Kg/m2 Kg/m2 1.00 0.00615.00 400.003.90 VIGA At Wcm Wcv f1 Vg Kg 18,767.71 0.275 0.275 0.400 0.400 280.00 4,200.00 2,500.00 38,000.00 PESO DEL CONCRETO

- 2. 3/8" 0 CANTIDAD CANTIDAD CAPA 1 CAPA 2 CAPA 3 CAPA 1 CAPA 2 CAPA 3 APOYO B ACERO SUPERIOR ACARO INFERIOR CABILLA CANTIDAD CANTIDAD CAPA 1 CAPA 2 CAPA 3 CAPA 1 CAPA 2 CAPA 3 3/8" 0 0 0 0 0 0 0 0 1/2" 0 0 0 2 0 0 0 0 5/8" 0 5 0 0 0 0 0 0 3/4" 2 0 0 0 0 0 0 0 7/8" 0 0 0 0 6 0 0 0 1" 5 0 0 0 0 0 0 0 1 3/8" 0 0 0 0 0 0 0 0 TRAMO A - B ACERO SUPERIOR ACARO INFERIOR CABILLA 0 0 0 0 0 0 0 1/2" 0 0 0 0 0 0 0 0 5/8" 0 0 0 0 0 0 0 0 3/4" 0 0 0 0 0 0 0 0 7/8" 0 0 0 0 4 0 0 0 1" 4 0 0 0 0 0 0 0 1 3/8" 0 0 0 0 0 0 0 0 4 Ø7/8" + ACEROS APOYO B 2 Ø3/4" +5 Ø1" + 5 Ø5/8" + 2 Ø1/2" + 6 Ø7/8" + ACEROS TRAMO A - B 4 Ø1" +

- 3. ACEROS DE REFUERZO. AREA TOTAL x Y AREA TOTAL AREA TOTAL x Y AREA TOTAL 7.22250 0.00000 11.19125 28.35345 7.22250 0.00000 8.01625 79.33386 7/8" 0 0.00 0.00 0 0.00000 10.55625 0.00000 0 0.00000 10.55625 0.00000 10.55625 0.000003/4" 0.75 0.00 0.00 0 0.00000 1/2" 0 1.27 1.27 2 2.53354 0 0.00000 7.22250 0.00000 7/8" 0 0.00 0.00 0 0.00000 5/8" 0 1.59 1.98 5 9.89663 0.00000 0.00000 39.36167 0.00000 1/2" 0 0.00 0.00 0 0.00000 6.90500 7/8" 0 0.00 0.00 0 0.00000 5.95250 3/4" 0.75 1.91 2.85 2 5.70046 0 0.00000 5.95250 5/8" 0 0.00 0.00 0 0.00000 5.95250 pulg cm cm2 ∑ 0.375 0.9525 0.71256 38.40 293.43678 ESTRIBO DIAMETRO AREA = ∑ = 7.64 cm 0.00000 1 3/8" 0 0.00 0.00 0 0.00000 10.55625 0.00000 0.00000 10.55625 0.00000 1" 1 0.00 0.00 0 0.00000 10.55625 3 3/8" 0 0.00 0.00 0 5/8" 0 0.00 0.00 0.00000 1 3/8" 0 0.00 0.00 0 0.00000 7.22250 0.00000 0.00000 7.22250 0.00000 1" 1 0.00 0.00 0 0.00000 7.22250 2 3/8" 0 0.00 0.00 0 3/4" 0.75 0.00 0.00 146.38779 1 3/8" 0 0.00 0.00 0 0.00000 5.95250 0.00000 0.00000 5.95250 0.00000 1" 1 2.54 5.07 4 20.26830 7.22250 1 3/8" 0 0.00 0.00 0 1/2" 0 0.00 0.00 AREA TOTAL Y AREA TOTAL x Y pulg cm cm2 cm2 cm cm3 1. CAPA TIPO DIAMETRO AREA CANTIDAD CAPA TIPO DIAMETRO AREA AREA TOTAL x Y pulg cm cm2 cm2 cm cm3 CANTIDAD AREA TOTAL Y 1 3/8" 0 0.00 0.00 0 3/4" 0 0.00 0.00 0.00000 5.95250 0.00000 1/2" 0 0.00 0.00 0 0.00000 5.95250 0.00000 5/8" 0 0.00 0.00 0 0.00000 5.95250 0.00000 0 0.00000 5.95250 0.00000 7/8" 0.875 2.22 3.88 5 19.39740 7.06375 137.01835 1" 0 0.00 0.00 0 0.00000 5.95250 0.00000 1 3/8" 0 0.00 0.00 0 0.00000 5.95250 0.00000 2 3/8" 0 0.00 0.00 0 0.00000 7.06375 0.00000 1/2" 0 0.00 0.00 0 0.00000 7.06375 0.00000 5/8" 0 0.00 0.00 0 0.00000 7.06375 0.00000 3/4" 0 0.00 0.00 0 0.00000 7.06375 0.00000 7/8" 0.875 0.00 0.00 0 0.00000 7.06375 0.00000 1" 0 0.00 0.00 0 0.00000 7.06375 0.00000 1 3/8" 0 0.00 0.00 0 0.00000 7.06375 0.00000 3 3/8" 0 0.00 0.00 0 0.00000 9.60375 0.00000 9.60375 0.00000 0.00000 1/2" 0 0.00 0.00 0 0.00000 0 0.00 0.00 0 0.00000 0 0.00 0.00 0 0.00000 9.60375 0.00000 5/8" 7/8" 0.875 0.00 0.00 0 0.00000 3/4" 1" 0 0.00 0.00 0 0.00000 1 3/8" 0 0.00 0.00 0 0.00000 9.60375 137.01835 ∑ = 7.06 cm ∑ 9.60375 0.00000 19.40 0.00000 9.60375 0.00000 9.60375 APOYO "A" - ACERO SUPERIOR APOYO "A" - ACERO INFERIOR YgSuperior YgInferior = = 293.4368 cm3 38.3989 cm2 = 137.0184 cm3 19.3974 cm2

- 4. AREA TOTAL x Y AREA TOTAL AREA TOTAL x Y AREA TOTAL APOYO "B" - ACERO SUPERIOR CAPA TIPO DIAMETRO AREA CANTIDAD AREA TOTAL Y AREA TOTAL x Y pulg cm cm2 cm2 cm cm3 1 3/8" 0 0.00 0.00 0 3/4" 0.75 1.91 2.85 0.00000 5.95250 0.00000 1/2" 0 0.00 0.00 0 0.00000 5.95250 0.00000 5/8" 0 0.00 0.00 0 0.00000 5.95250 0.00000 2 5.70046 6.90500 39.36167 7/8" 0 0.00 0.00 0 0.00000 5.95250 0.00000 1" 1 2.54 5.07 5 25.33537 7.22250 182.98474 1 3/8" 0 0.00 0.00 0 0.00000 5.95250 0.00000 2 3/8" 0 0.00 0.00 0 0.00000 7.22250 0.00000 1/2" 0 0.00 0.00 0 0.00000 7.22250 0.00000 5/8" 0 1.59 1.98 5 9.89663 8.01625 79.33386 3/4" 0.75 0.00 0.00 0 0.00000 7.22250 0.00000 7/8" 0 0.00 0.00 0 0.00000 7.22250 0.00000 1" 1 0.00 0.00 0 0.00000 7.22250 0.00000 1 3/8" 0 0.00 0.00 0 0.00000 7.22250 0.00000 3 3/8" 0 0.00 0.00 0 0.00000 10.55625 0.00000 1/2" 0 1.27 1.27 2 2.53354 11.19125 28.35345 5/8" 0 0.00 0.00 0 0.00000 10.55625 0.00000 3/4" 0.75 0.00 0.00 0 0.00000 10.55625 0.00000 7/8" 0 0.00 0.00 0 0.00000 10.55625 0.00000 1" 1 0.00 0.00 0 0.00000 10.55625 0.00000 1 3/8" 0 0.00 0.00 0 0.00000 10.55625 0.00000 43.47 330.03372 ESTRIBO YgSuperior = ∑ = 330.0337 cm3 = 7.59 cm DIAMETRO AREA ∑ 43.4660 cm2 pulg cm cm2 0.375 0.9525 0.71256 YgInferior = ∑ = 164.4220 cm3 = 7.06 cm ∑ 23.2769 cm2 APOYO "B" - ACERO INFERIOR CAPA TIPO DIAMETRO AREA CANTIDAD AREA TOTAL Y AREA TOTAL x Y pulg cm cm2 cm2 cm cm3 1 3/8" 0 0.00 0.00 0 3/4" 0 0.00 0.00 0.00000 5.95250 0.00000 1/2" 0 0.00 0.00 0 0.00000 5.95250 0.00000 5/8" 0 0.00 0.00 0 0.00000 5.95250 0.00000 0 0.00000 5.95250 0.00000 7/8" 0.875 2.22 3.88 6 23.27687 7.06375 164.42202 1" 0 0.00 0.00 0 0.00000 5.95250 0.00000 1 3/8" 0 0.00 0.00 0 0.00000 5.95250 0.00000 2 3/8" 0 0.00 0.00 0 0.00000 7.06375 0.00000 1/2" 0 0.00 0.00 0 0.00000 7.06375 0.00000 5/8" 0 0.00 0.00 0 0.00000 7.06375 0.00000 3/4" 0 0.00 0.00 0 0.00000 7.06375 0.00000 7/8" 0.875 0.00 0.00 0 0.00000 7.06375 0.00000 1" 0 0.00 0.00 0 0.00000 7.06375 0.00000 1 3/8" 0 0.00 0.00 0 0.00000 7.06375 0.00000 3 3/8" 0 0.00 0.00 0 0.00000 9.60375 0.00000 1/2" 0 0.00 0.00 0 0.00000 9.60375 0.00000 5/8" 0 0.00 0.00 0 0.00000 9.60375 0.00000 3/4" 0 0.00 0.00 0 0.00000 9.60375 0.00000 7/8" 0.875 0.00 0.00 0 0.00000 9.60375 0.00000 1" 0 0.00 0.00 0 0.00000 9.60375 0.00000 1 3/8" 0 0.00 0.00 0 0.00000 9.60375 0.00000 23.28 164.42202

- 5. AREA TOTAL x Y AREA TOTAL AREA TOTAL x Y AREA TOTAL TRAMO "A - B" - ACERO SUPERIOR CAPA TIPO DIAMETRO AREA CANTIDAD AREA TOTAL Y AREA TOTAL x Y pulg cm cm2 cm2 cm cm3 1 3/8" 0 0.00 0.00 0 3/4" 0 0.00 0.00 0.00000 5.95250 0.00000 1/2" 0 0.00 0.00 0 0.00000 5.95250 0.00000 5/8" 0 0.00 0.00 0 0.00000 5.95250 0.00000 0 0.00000 5.95250 0.00000 7/8" 0 0.00 0.00 0 0.00000 5.95250 0.00000 1" 1 2.54 5.07 4 20.26830 7.22250 146.38779 1 3/8" 0 0.00 0.00 0 0.00000 5.95250 0.00000 2 3/8" 0 0.00 0.00 0 0.00000 7.22250 0.00000 1/2" 0 0.00 0.00 0 0.00000 7.22250 0.00000 5/8" 0 0.00 0.00 0 0.00000 7.22250 0.00000 3/4" 0 0.00 0.00 0 0.00000 7.22250 0.00000 7/8" 0 0.00 0.00 0 0.00000 7.22250 0.00000 1" 1 0.00 0.00 0 0.00000 7.22250 0.00000 1 3/8" 0 0.00 0.00 0 0.00000 7.22250 0.00000 3 3/8" 0 0.00 0.00 0 0.00000 9.76250 0.00000 1/2" 0 0.00 0.00 0 0.00000 9.76250 0.00000 5/8" 0 0.00 0.00 0 0.00000 9.76250 0.00000 3/4" 0 0.00 0.00 0 0.00000 9.76250 0.00000 7/8" 0 0.00 0.00 0 0.00000 9.76250 0.00000 1" 1 0.00 0.00 0 0.00000 9.76250 0.00000 1 3/8" 0 0.00 0.00 0 0.00000 9.76250 0.00000 20.27 146.38779 ESTRIBO YgSuperior = ∑ = 146.3878 cm3 = 7.22 cm DIAMETRO AREA ∑ 20.2683 cm2 pulg cm cm2 0.375 0.9525 0.71256 YgInferior = ∑ = 109.6147 cm3 = 7.06 cm ∑ 15.5179 cm2 TRAMO "A - B" - ACERO INFERIOR CAPA TIPO DIAMETRO AREA CANTIDAD AREA TOTAL Y AREA TOTAL x Y pulg cm cm2 cm2 cm cm3 1 3/8" 0 0.00 0.00 0 3/4" 0 0.00 0.00 0.00000 5.95250 0.00000 1/2" 0 0.00 0.00 0 0.00000 5.95250 0.00000 5/8" 0 0.00 0.00 0 0.00000 5.95250 0.00000 0 0.00000 5.95250 0.00000 7/8" 0.875 2.22 3.88 4 15.51792 7.06375 109.61468 1" 0 0.00 0.00 0 0.00000 5.95250 0.00000 1 3/8" 0 0.00 0.00 0 0.00000 5.95250 0.00000 2 3/8" 0 0.00 0.00 0 0.00000 7.06375 0.00000 1/2" 0 0.00 0.00 0 0.00000 7.06375 0.00000 5/8" 0 0.00 0.00 0 0.00000 7.06375 0.00000 3/4" 0 0.00 0.00 0 0.00000 7.06375 0.00000 7/8" 0.875 0.00 0.00 0 0.00000 7.06375 0.00000 1" 0 0.00 0.00 0 0.00000 7.06375 0.00000 1 3/8" 0 0.00 0.00 0 0.00000 7.06375 0.00000 3 3/8" 0 0.00 0.00 0 0.00000 9.60375 0.00000 1/2" 0 0.00 0.00 0 0.00000 9.60375 0.00000 5/8" 0 0.00 0.00 0 0.00000 9.60375 0.00000 3/4" 0 0.00 0.00 0 0.00000 9.60375 0.00000 7/8" 0.875 0.00 0.00 0 0.00000 9.60375 0.00000 1" 0 0.00 0.00 0 0.00000 9.60375 0.00000 0 0.00 0.00 0 0.00000 9.60375 0.00000 15.52 109.61468 1 3/8"

- 6. MOMENTO RESISTENTE. APOYO "A" = = = = = = = = - = - = = ( ) = ≤ = = = ( ) + + = x = x = ( ) x x x x x = = ACI 21.2.2, Fig R21.2 ACI 22.2.2.4.1 62.36 cm 20.27 7.59 cm 15.52 7.22 cmTRAMO "A - B" APOYO "B" APOYO "A" SUPERIOR 38.40 ACERO DE REFUERZO SUPERIOR INFERIOR Yg cm2 cm2 cm cm 7.06 cm ZONA RESUMEN 19.40 7.64 cm 7.06 cm 43.47 23.28 7.06 cm INFERIOR 2. d h Yg 62.36 cm h r Yg 7.64 cm Assup Fy 4,200.00 Kg/cm2 b 45.00 cm ß = 1.05 - f'c 70.00 cm 0.65 = 0.85 = 0.851.05 - 280.00 Kg/cm2 Єcmax Si f'c > 280.00 Kg/cm2 1400 ß 0.85 Si ≥ ß 0.85 Cmax = Єcmax x d = f'c 280.00 Kg/cm2 0.003 Єcmin 0.005 Єcmax Єcmin a = Assup fy = a max ß Cmax 19.88 cm 0.85 F'c b 0.85 23.38 cm a ≤ amax SI SIMPLEMENTE ARMADA NO DOBLEMENTE ARMADA C ey = fy = 0.002 Es f'c 280.00 Kg/cm2 = 45.00 cm = 0.005 ACI 22.2.2.4.3 1400 x 0.003 280.00 Kg/cm2 x 2,100,000.00 Kg/cm2 4,200.00 Kg/cm2 = 2.1. 38.40 cm2 70.00 cm 7.64 cm ecu 0.003 Es 0.003 4,200.00 Kg/cm2 0.85 = 15.06 cm 2,100,000.00 Kg/cm2 23.38 cm 38.40 cm2 Asinf 19.40 cm2

- 7. x x x x x x x = = ( ) ≤ = > = > < = = ( ) As = As' = = = - ( ) - = x x x = x x x = ( ) ( ) ACI 21.2.1, 21.2.4 0.013684 4,200.00 Kg/cm2x 50.69 cm2 4,200.00 Kg/cm2 x 0.6236 m - 0.1988 m x 0.90 2 Ø 2 As1 = 100,431.90 Kg x m x = 2 As1 = Muc Fy x d - amax ACI 22.2.2.4.1 2 Muc = C x d - = 100,431.90 Kg x mMuc = 212,879.21 Kg x 0.6236 m - 212,879.21 Kg ACI ACI 22.2.2.4.1 0.1988 m x 0.90 amax x Ø ACI C 0.85 f'c b amax C 19.88 cm es = ecu x ß 0.85 f'c - 1 = 0.0075598 ρreal 0.003 x 0.85 0.85 = Ascol = 0.013684 ρreal fy b d 45.00 cm 62.36 cm ey 0.002 es 0.00756 es ey Ø 0.65 0.90 es ey es 0.005 Ø 1.11 0.90 x Ø es 0.005 Ø ACI 9.3.3.1, 21.2.2 = Ascolocada x fy x a Para Doblemente Armada = 38.40 cm2 Para Simplemente Armada 2 d -Mr Ø 0.90 = 38.40 cm2 = 79,583.17 Kg x m 280.00 Kg/cm2 = 38.40 cm2 x 4,200.00 Kg/cm2 x 0.62 m - 1 Mr x f's = Es x - 0.15 m 2 0.85 280.00 Kg/cm2 45.00 cm 0.003 x ACI 19.40 cm2 Єcmax x Cmax d' ≤ Fy f's = 4,200.00 Kg/cm2 9.2.1.2, 9.5.2.1, 20.2.2, 22.2.1.2 Cmax f's = 2,100,000.00 Kg/cm2 x 23.38 cm 7.06 cm = 4,396.95 Kg/cm2 23.38 cm d' YgInferior 7.06 cm

- 8. = = x x x x x x x x x x x x x x x x = - = - =d h Yg 70.00 cm 7.06 cm 62.94 cm 100,431.90 Kg x m= + -25,680.60 Kg x m 74,751.30 Kg x m= 59,250.40 Kg x m 0.85 f'c -25,680.60 Kg x mMus x 0.90 = Muc + Mus x 0.6236 m - 0.0706 m Mr = - d' Øx = -12.29 cm2 x 4,200.00 Kg/cm2 = -12.29 cm2 Mus = As2 x Fy x d As2 = As - As1 = 38.40 cm2 - 50.69 cm2 x fy x = b 9.51 cm Muinf = Ø x As inf a = As inf = x fy x λ x = 106,737.57 Kg x m 0.85 f'c b = Ø x As sup 1.00 a = As sup fy Musup As sup = 38.40 cm2 λ 19.40 cm2 1.25 79,583.17 Kg x m x 0.63 m 4,200.00 Kg/cm2 1.25 As inf = 38.40 cm2 Musup = Mr = 4,200.00 Kg/cm2 x 1.25 18.82 cm Ø 1.00 λ = - 19.40 cm2 x 280.00 Kg/cm2 45.00 cm0.85 fy λ x 38.40 cm2 x 4,200.00 Kg/cm2 a 2 d - a 2 d - 0.85 280.00 Kg/cm2 45.00 cm x 1.25 x 0.62 m = 0.0951 m 2 Muinf 0.1882 m 2 Musup = 19.40 cm2 4,200.00 Kg/cm2 1.25 -Muinf = 1.00 x

- 9. APOYO "B" = = = = = = = = - = - = = ( ) = ≤ = = = ( ) + + = x = x = ( ) x x x x x = = x x x x x x x = = ( ) ≤ = > = > < = =Ø 0.90es ey es 0.005 Ø 1.01 es 0.00634 ACI 21.2.1, 21.2.4 Ø 0.65 es 0.005 Ø 0.90 0.0063361 ρreal fy 0.0154776 x 4,200.00 Kg/cm2 0.85 0.85 280.00 Kg/cm2 - 1 = 45.00 cm 62.41 cm es = ecu x ß 0.85 0.002 ρreal = Ascol = 43.47 cm2 = 0.0154776 b d ecu 0.003 Es 2,100,000.00 Kg/cm2 ey = fy = 4,200.00 Kg/cm2 = amax SI SIMPLEMENTE ARMADA NO DOBLEMENTE ARMADA C Es 2,100,000.00 Kg/cm2 = 17.05 cm 0.85 F'c 0.85 280.00 Kg/cm2 45.00 cmb ACI 22.2.2.4.1 a = Assup fy = 43.47 cm2 x 4,200.00 Kg/cm2 Єcmax Єcmin 0.003 0.005 a max ß Cmax 0.85 23.40 cm 19.89 cm = 0.003 x 62.41 cm = 23.40 cm ß 0.85 Єcmax 0.003 Єcmin 0.005 ACI 21.2.2, Fig R21.2 280.00 Kg/cm2 = 0.85 = 0.85 ß 0.85 Si f'c 280.00 Kg/cm2 f'c ≥ 0.65 = 1.05 - Si f'c > 280.00 Kg/cm2 ACI 22.2.2.4.3 280.00 Kg/cm2 d h Yg 70.00 cm 7.59 cm 62.41 cm Fy 4,200.00 Kg/cm2 7.59 cm Assup 43.47 cm2 Asinf 23.28 cm2 f'c Yg 2.2. h 70.00 cm b 45.00 cm r 1 = 0.003 x es ey f'c - ey 0.002 a ≤ xCmax = Єcmax d 14001400 ß = 1.05 -

- 10. ( ) As = As' = = = - ( ) - = x x x = x x x = ( ) ( ) = -19,070.85 Kg x m -119,660.26 Kg x m Mr = Muc + Mus = 100,589.41 Kg x m + -119,660.26 Kg x m 4,200.00 Kg/cm2 x 0.6241 m - 0.0000 m x 50.73 cm2 = -50.73 cm2 Mus = As2 x Fy x d x 0.90 As2 = As - As1 = 0.00 cm2 - As1 = 100,589.41 Kg x m = 50.73 cm2 4,200.00 Kg/cm2 x 0.6241 m - 0.1989 m As1 = Muc Fy x d - amax x Ø ACI 22.2.2.4.1 Muc = 213,046.08 Kg x 0.6241 m - 0.1989 m x 0.90 d - amax x Ø ACI 2 280.00 Kg/cm2 45.00 cm 19.89 cm C 213,046.08 Kg ACI ACI 22.2.2.4.1 C 0.85 f'c b amax 0.85 7.06 cm = 4,398.44 Kg/cm2 23.40 cm 0.003 x 23.40 cm f's = 4,200.00 Kg/cm2 ACI 9.2.1.2, 9.5.2.1, 20.2.2, 22.2.1.2 Cmax f's = 2,100,000.00 Kg/cm2 x Єcmax x Cmax d' ≤ Fy = 88,532.77 Kg x m Para Doblemente Armada 43.47 cm2 23.28 cm2 d' YgInferior 7.06 cm = 43.47 cm2 x 4,200.00 Kg/cm2 x 0.62 m - a x Øx d ACI 9.3.3.1, 21.2.2 Para Simplemente Armada Mr = Ascolocada x fy =Mus = -50.73 cm2 x - d' x Ø 2 2 = 100,589.41 Kg x m 2 Muc = C x f's = Es x 2 - 0.17 m x 0.90 0.90Mr 2

- 11. = = x x x x x x x x x x x x x x x x = - = - = 1.25 0.1141 m Muinf = 69,938.50 Kg x m Yg 70.00 cm 7.06 cm 62.94 cm Muinf = 1.00 x 23.28 cm2 x x d - a d h 4,200.00 Kg/cm2 1.25 = 11.41 cm 0.85 f'c b 0.85 280.00 Kg/cm2 45.00 cm = As inf fy λ = 23.28 cm2 Musup = 118,100.02 Kg x m 2 x 1.25 x4,200.00 Kg/cm2 x fy 0.62 m - 0.2131 m Musup = 1.00 x 43.47 cm2 x x λ x d = 21.31 cm a 0.85 f'c b 0.85 280.00 Kg/cm2 45.00 cm = 43.47 cm2 4,200.00 Kg/cm2 1.25 23.28 cm2 Ø 1.00 λ 1.25 a = As sup fy λ Mr = 88,532.77 Kg x m As sup = 43.47 cm2 As inf = Muinf = Ø x 2 As inf x fy 2 x 0.63 m -4,200.00 Kg/cm2 x 2 Musup a -= Ø x As sup

- 12. TRAMO "A - B" = = = = = = = = - = - = = ( ) = ≤ = = = ( ) + + = x = x = ( ) x x x x x = = x x x x x x x = = ( ) ≤ = > = > < = = h 70.00 cm b 45.00 cm r 2.3. Yg 0.00 cm Assup 15.52 cm2 Asinf 20.27 cm2 f'c 280.00 Kg/cm2 Yg 70.00 cm 7.06 cm 62.94 cm Fy 4,200.00 Kg/cm2 Si f'c > 280.00 Kg/cm2 ACI 22.2.2.4.3 d h 1400 ß = 1.05 - f'c ≥ 1400 = 0.85 = 0.850.65 = 1.05 Si f'c 280.00 Kg/cm2 - 280.00 Kg/cm2 ß 0.85 Єcmax 0.003 Єcmin 0.005 ACI 21.2.2, Fig R21.2 ß 0.85 Cmax = Єcmax Єcmax Єcmin x ACI 22.2.2.4.1 d = 0.003 x 62.94 cm 0.003 0.005 = 15.52 cm2 = 23.60 cm a max ß Cmax 0.85 23.60 cm 20.06 cm 4,200.00 Kg/cm2 = 6.09 cm 0.85 F'c b 0.85 280.00 Kg/cm2 45.00 cm Assup a ≤ amax SI SIMPLEMENTE ARMADA x NO DOBLEMENTE ARMADA a = fy ecu 0.003 Es 2,100,000.00 Kg/cm2 ey = fy = 4,200.00 Kg/cm2 = Es 2,100,000.00 Kg/cm2 0.002 ρreal = Ascol = 15.52 cm2 = 0.0054792 b d 45.00 cm 62.94 cm - 1 = 0.003es = ecu x ß 0.85 ρreal fy 0.85 0.85 280.00 Kg/cm2f'c - 1 = 0.0233723 0.0054792 x 4,200.00 Kg/cm2 ey 0.002 es 0.02337 ACI x es ey Ø 0.65 es 0.005 ey es 0.005 Ø 2.43 21.2.1, 21.2.4 Ø 0.90 0.90es Ø C

- 13. ( ) As = As' = = = - ( ) - = x x x = x x x = ( ) ( ) Para Simplemente Armada Mr = Ascolocada x fy x d x Ø ACI 9.3.3.1, 21.2.2 2 = 2 Mr = 15.52 cm2 x 4,200.00 Kg/cm2 x 35,132.18 Kg x m Para Doblemente Armada 0.63 m - 0.06 m x d' YgInferior 7.22 cm 0.90 f's = Es x Єcmax ACI 9.2.1.2, 9.5.2.1, 20.2.2, 22.2.1.2 15.52 cm2 x Cmax d' ≤ Fy Cmax 20.27 cm2 - a 4,372.05 Kg/cm2 23.60 cm f's = 4,200.00 Kg/cm2 f's = 2,100,000.00 Kg/cm2 x 0.003 0.85 f'c b 23.60 cm 7.22 cm =x 45.00 cm 20.06 cm C 214,852.56 Kg ACI ACI 22.2.2.4.1 amax 0.85 280.00 Kg/cm2C Muc = C x d - amax x Ø ACI ACI 22.2.2.4.1 2 Muc = 214,852.56 Kg x 0.6294 m - 0.2006 m x 0.90 = 102,302.49 Kg x m 2 4,200.00 Kg/cm2 x As1 = Muc Fy x d - amax 0.90 2 x Ø 2 As1 = 102,302.49 Kg x m As - As1 = = 51.16 cm2 0.6294 m - 0.2006 m x 51.16 cm2 = -51.16 cm2 Mus = As2 x Fy As2 = x 4,200.00 Kg/cm2 x d - d' x 0.00 cm2 - x 0.6294 m Ø Mus = -51.16 cm2 - 0.0000 m x 0.90 = -121,698.13 Kg x m -121,698.13 Kg x m = -19,395.64 Kg x mMr = Muc + Mus = 102,302.49 Kg x m +

- 14. = = x x x x x x x x x x x x x x x x = - = - = 48,174.97 61,514.56 ZONA RESUMEN SUPERIOR INFERIOR Kg x m Kg x m 106,737.57 59,250.40- RESISTENTE 88,532.77 - 118,100.02 69,938.50 - 35,132.18 APOYO "A" APOYO "B" TRAMO "A - B" SUPERIOR Kg x m 79,583.17 Kg x m 0.0994 m 2 Muinf = 61,514.56 Kg x m INFERIOR MAXIMO PROBABLE MOMENTO 4,200.00 Kg/cm2 x 1.25 x 0.63 m -Muinf = 1.00 x 20.27 cm2 x h Yg 70.00 cm 7.22 cm 62.78 cm 2 fy x d - a d Muinf = Ø x As inf x 0.85 f'c b 0.85 280.00 Kg/cm2 45.00 cm = 20.27 cm2 4,200.00 Kg/cm2 1.25 = 9.94 cm 0.0761 m 2 Musup = 48,174.97 Kg x m a = As inf fy λ 4,200.00 Kg/cm2 x 1.25 x a 2 0.63 m -Musup = 1.00 x 15.52 cm2 x x λ x d - 35,132.18 Kg x m As sup = 15.52 cm2 As inf = 20.27 cm2 Mr = Ø 1.00 λ 1.25 a = As sup fy λ = = 0.85 f'c b 0.85 15.52 cm2 7.61 cm 280.00 Kg/cm2 45.00 cm Musup = Ø x As sup x fy 4,200.00 Kg/cm2 1.25

- 15. DISEÑO A CORTE CORTE ISOSTATICO. ( ) = = = = = = = = = = x = x = = x x = x x = = + = + = = x = x = = x = x = = x + x x + x = x + x x + x = x x = = = = + + = + + = = ( ; ) = ( ; ) = = + = + = 3. 3.1. ACI 18.4.2.4 ; Fig. R18.4.2 615.00 Kg/m2 Wcv 400.00 Kg/m2 400.00 Kg/m2 Wu 1.20 Cp f1 Ln 6.53 m At Wcm 2,398.50 Kg / m S At 3.90 m 787.50 Kg / m f1 1.00 Cv 0.20 S 0.00 Kg / m Cv At Wcv 1,560.00 Kg / m Pp 615.00 Kg/m2 3.90 m 1,560.00 Kg / m 0.20 0.00 Kg / m Wu Ln 6,319.20 Kg / m 6.53 m Ss Wu 6,319.20 Kg / m At 3.90 m Wcm 3.90 m 0.00 Kg/m2 S 0.00 Kg/m2 γconcreto b h 2,500.00 Kg/m3 0.45 m b 0.45 m h 0.70 m γconcreto 2,500.00 Kg/m3 1.60 1.60 0.70 m Cp1 Cp Cp1 Pp 2,398.50 Kg / m 787.50 Kg / m 3,186.00 Kg / m = 20,616.39 Kg Vg = 18,767.71 Kg Wu 1.20 3,186.00 Kg / m 1.00 2 Vp1 27,076.79 Kg Vg = = 2 59,250.40 Kg x m Mu apoyo "B" - Superior 118,100.02 Kg x m Mu apoyo "B" - Inferior 69,938.50 Kg x m Mu apoyo "A" - Superior Mu apoyo "B" - Inferior Mu apoyo "A" - Superior 106,737.57 Kg x m Mu apoyo "A" - Inferior Ln Vp1 = 106,737.57 Kg x m = 69,938.50 Kg x m 6.525 m Vp2 27,180.14 Kg Vp2 = Mu apoyo "B" - Superior Mu apoyo "A" - Inferior Vp1 Vp2 max 27,076.79 Kg 59,250.40 Kg x m Ln 6.525 m = 118,100.02 Kg x m 27,180.14 Kg 27,180.14 Kg Vu1 Vp Vg 27,180.14 Kg 18,767.71 Kg 45,947.85 Kg Vp max

- 16. = = = ( ; ; ) = ( ; ; ) = = Para Concretos de peso normal = = Para Concretos Livianos = > > = x x x x x ( ) = x x x x x = > > = = = x x x x ( ) = x x x x = + x x x = + x x x = = + = + = x x x x x x 45,947.85 Kg 0.75 = 37,000.00 Kg Vu apoyo "B" 38,000.00 Kg max Vu1 Vu apoyo "A" Vu apoyo "B" λ 37,000.00 Kg 38,000.00 Kgmax 45,947.85 Kg 1.00 = 45,947.85 Kg Ø Vu apoyo "A" Ø 0.75 ØVc Ø 0.53 f'c b λ λ 0.75 ACI 22.5.5.1 ØVc 0.75 0.53 280.00 Kg/cm2 45.00 cm 62.36 cm 18,664.75 Kg ØVs Ø 2.12 f'c b d ACI 22.5.1.2 ØVc ØVs 0.75 2.12 280.00 Kg/cm2 45.00 cm 62.36 cm d 9,332.38 Kg 74,659.01 Kg ØVc = 18,664.75 Kg = 9,332.38 Kg 2 2 0.75 3.5 45.00 cm 62.36 cm 2 16,698.44 Kg ØVc Ø 3.5 b ØVmax ØVc ØVs 18,664.75 Kg 74,659.01 Kg 93,323.77 Kg 0.0359 cm2/cm S Fy 4,200.00 Kg/cm2 Av1min = 0.2 f'c b = = 3.5 0.2 280.00 Kg/cm2 45.00 cm = 45.00 cm = 0.0375 cm2/cm S Fy 4,200.00 Kg/cm2 Av2min = 3.5 b ( 0.0359 cm2/cm Avmin = max ( Av1min ; ; 0.0375 cm2/cm ) S S S Av2min ) = max Avmin = 0.0375 cm2/cm S Vumax Vumax λ Vumax Vg 61,263.80 Kg 1.00 Si Si 18,767.71 Kg 45,947.85 Kg d 1.00 Vu = Vu1 Vg Vu1 18,767.71 Kg 45,947.85 Kg ØVc 0.00 Kg 0.00 Kg

- 17. - - x x x x > = = Si Vu < ØVc 2 45,947.85 Kg < 9,332.38 Kg Av = 0.0000 cm2/cm S ØVc < Vu < ØVmax 2 4,200.00 Kg/cm2 9,332.38 Kg < 45,947.85 Kg < 93,323.77 Kg ØVc = = 45,947.85 Kg 0.00 Kg = 0.2339 cm2/cm S Ø Fy d 0.75 ) 62.36 cm Av = max ( Av ; Avmin ) Aumentar Sección max ( 0.2339 cm2/cm ; 0.0375 cm2/cm 3 ramas = 0.2339 cm2/cm S S S Si Vu > ØVmax cm 45,947.85 Kg 93,323.77 Kg DIAMETRO Separación "S" N° Diametro AREA "db" 2 ramas 0.71 0.95 6.00 9.00 4 ramas pulg cm2 cm cm cm 12.00 4 1/2" 1.27 1.27 10.00 16.00 21.00 3 3/8" 36.00 48.00 5 5/8" 1.98 1.59 16.00 25.00 3.88 2.22 33.00 49.00 33.00 6 3/4" 2.85 1.91 24.00 66.00 8 1" 5.07 2.54 43.00 64.00 86.00 7 7/8" 11 1 3/8" 9.58 3.49 81.00 122.00 0.2339 cm2/cm Av = Vu Si So min 6.00 cm So Av 163.00 Av = S 6.00 cm

- 18. LONGITUD DE CONFINAMIENTO ( Lo ). ( ) = - r = = - - = = = ≤ = = x = > = = x = x = SEPARACIÓN DE ESTRIBOS EN ZONA CONFINADA (So). ( ) = x = = = = SEPARACIÓN DE ESTRIBOS EN ZONA NO CONFINADA (S). = x = = APOYO "B" 88,532.77 - TRAMO "A - B" - 35,132.18 Kg x m APOYO "A" 79,583.17 - RESUMEN ZONA MOMENTO RESISTENTE SUPERIOR INFERIOR Kg x m ACI 18.4.2.4 = d = 32.00 cm 2 < Ln / h Si 0.275 m 0.275 m 0.400 m 0.400 m ACI 18.4.2.4 S 12.00 cm 0.05 m 0.05 m Ø 3/8" @ 0.12 m Ø 3/8" @ 0.06 m Ø 3/8" @ 0.06 m 6.525 m 1.400 m 3.725 m 1.400 m 30.00 cm So 6.00 cm S1 So 2 12.00 cm 7.20 m S2 4 So3 24 Ø del estribo 22.00 cm So4 = 8 x Ø de la barra long. de menor diametro = 10.00 cm Lcf3 0.00 cm Lo 140.00 cm So1 = d = 16.00 cm So2 132.08 cm 6 h Lo3 2 h 140.00 cm Si Ln / h 10 + 2 = 132.08 cm Si 4 0.00 cm Lo2 = h x Ln ≤ 10 Lcf2 = Lo1 h 70.00 cm Ln / h 4 Lcf1 0.400 m 6.525 m Ln = 9.32143 h d h 65.00 cm Ln 7.20 m 0.275 m 70.00 cm 2 h 3.2. 3.3. 3.4. 2 So Av 6.00 cm