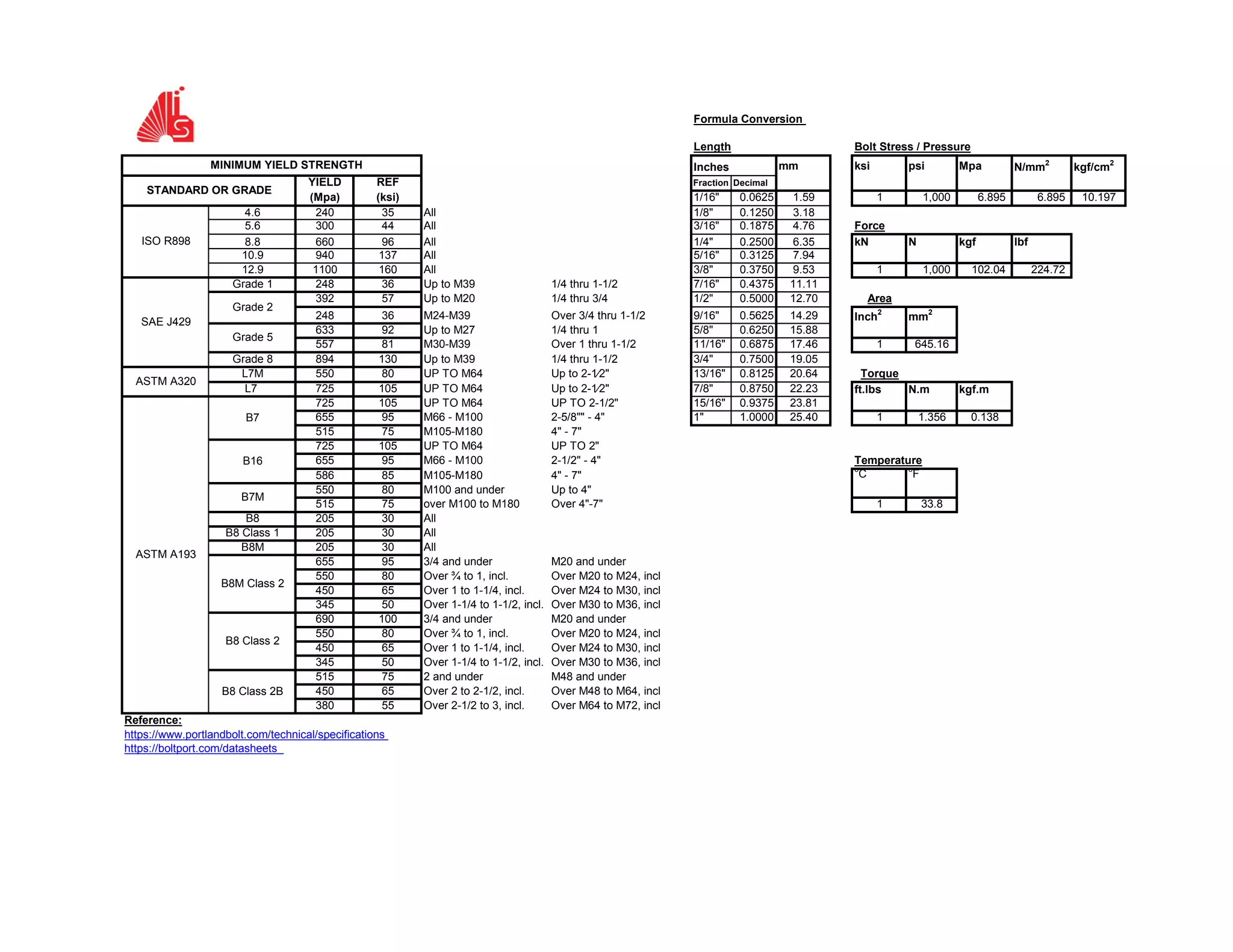

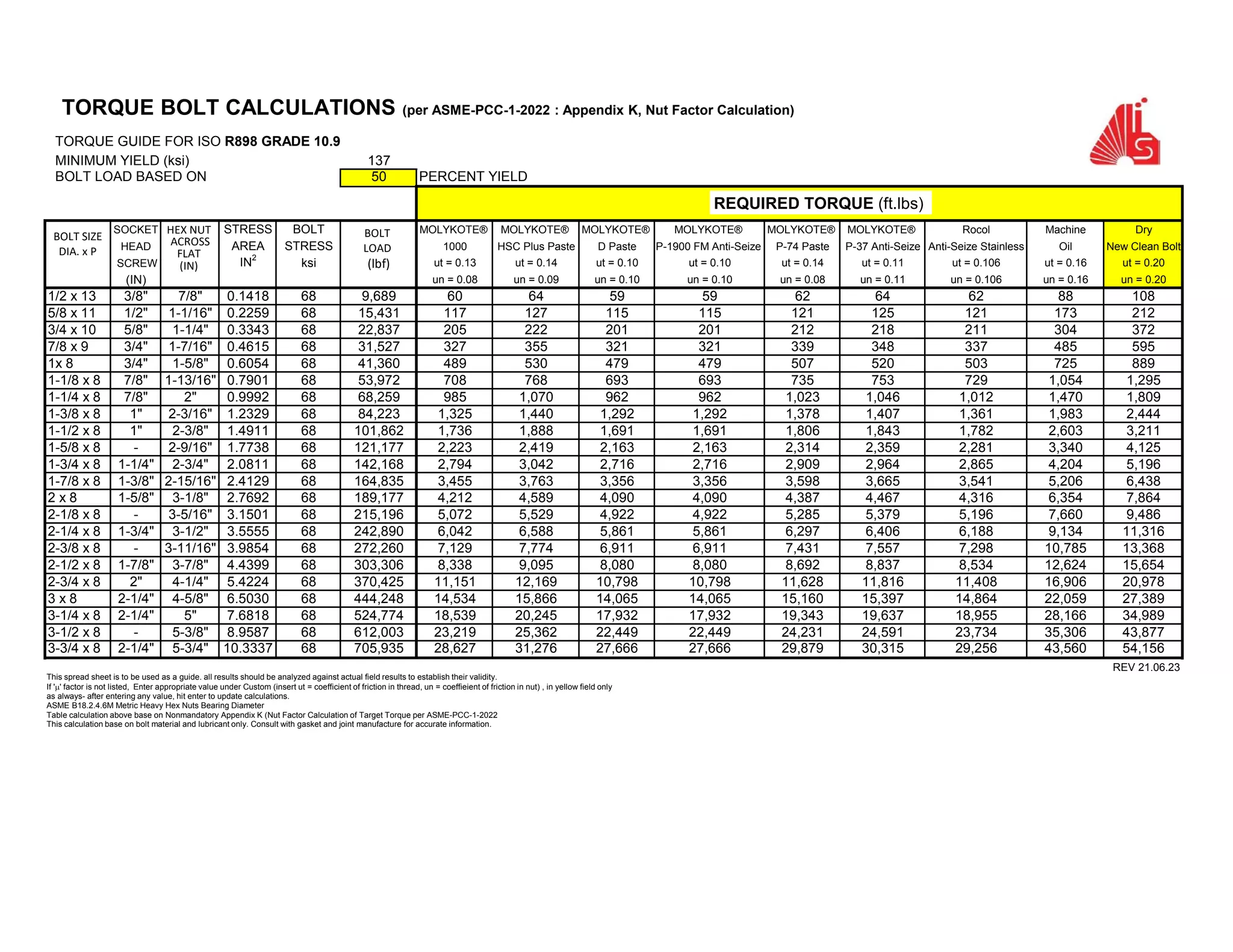

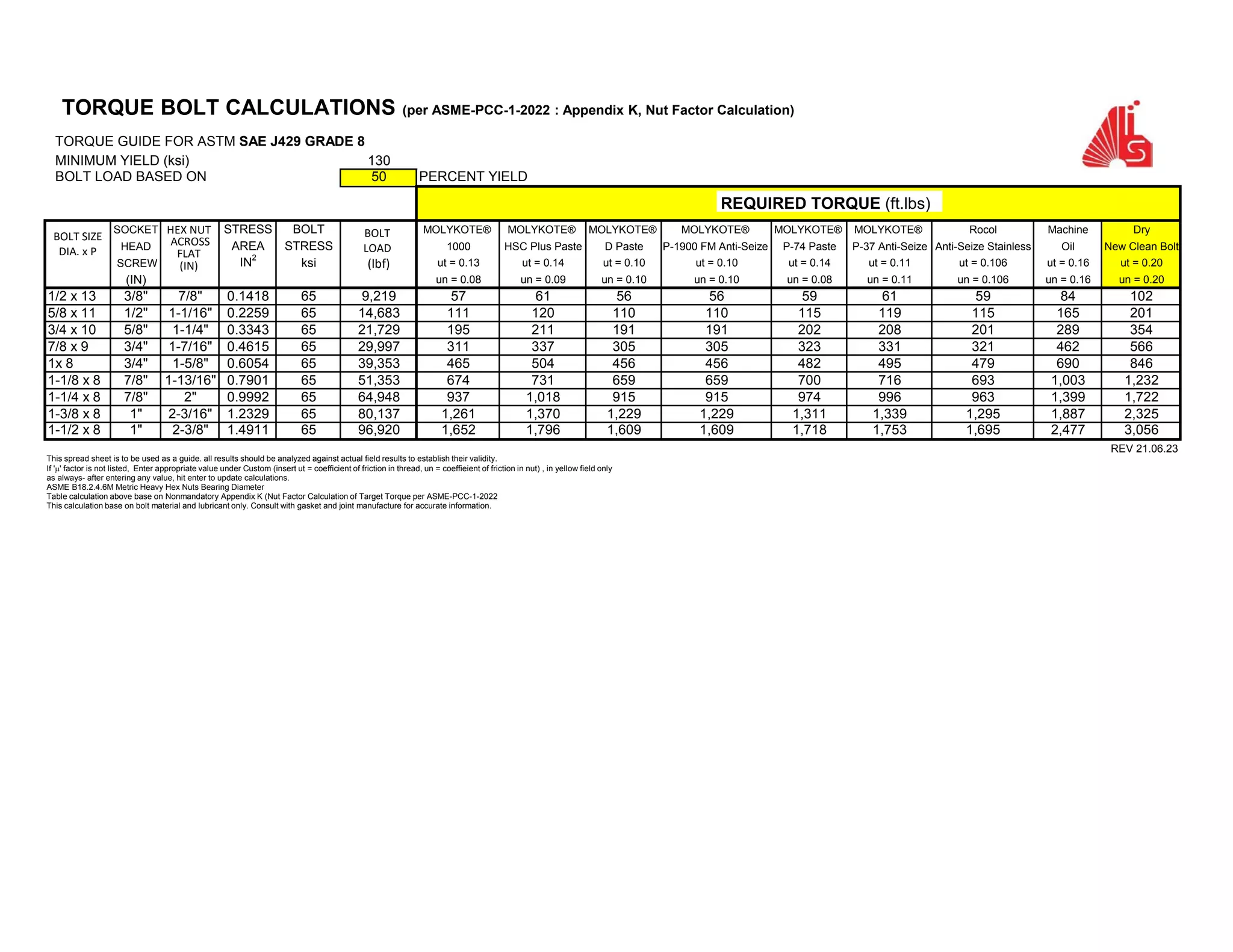

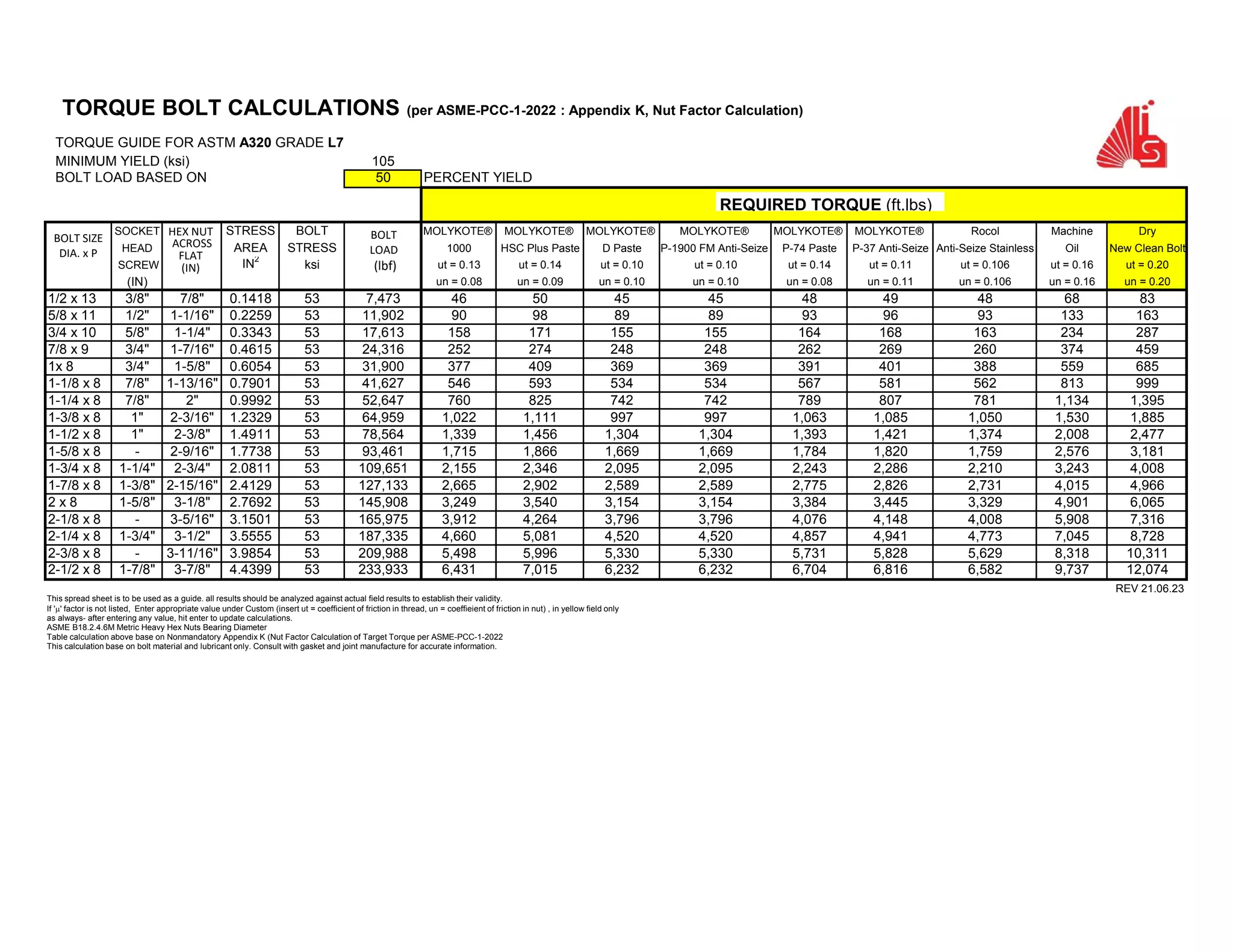

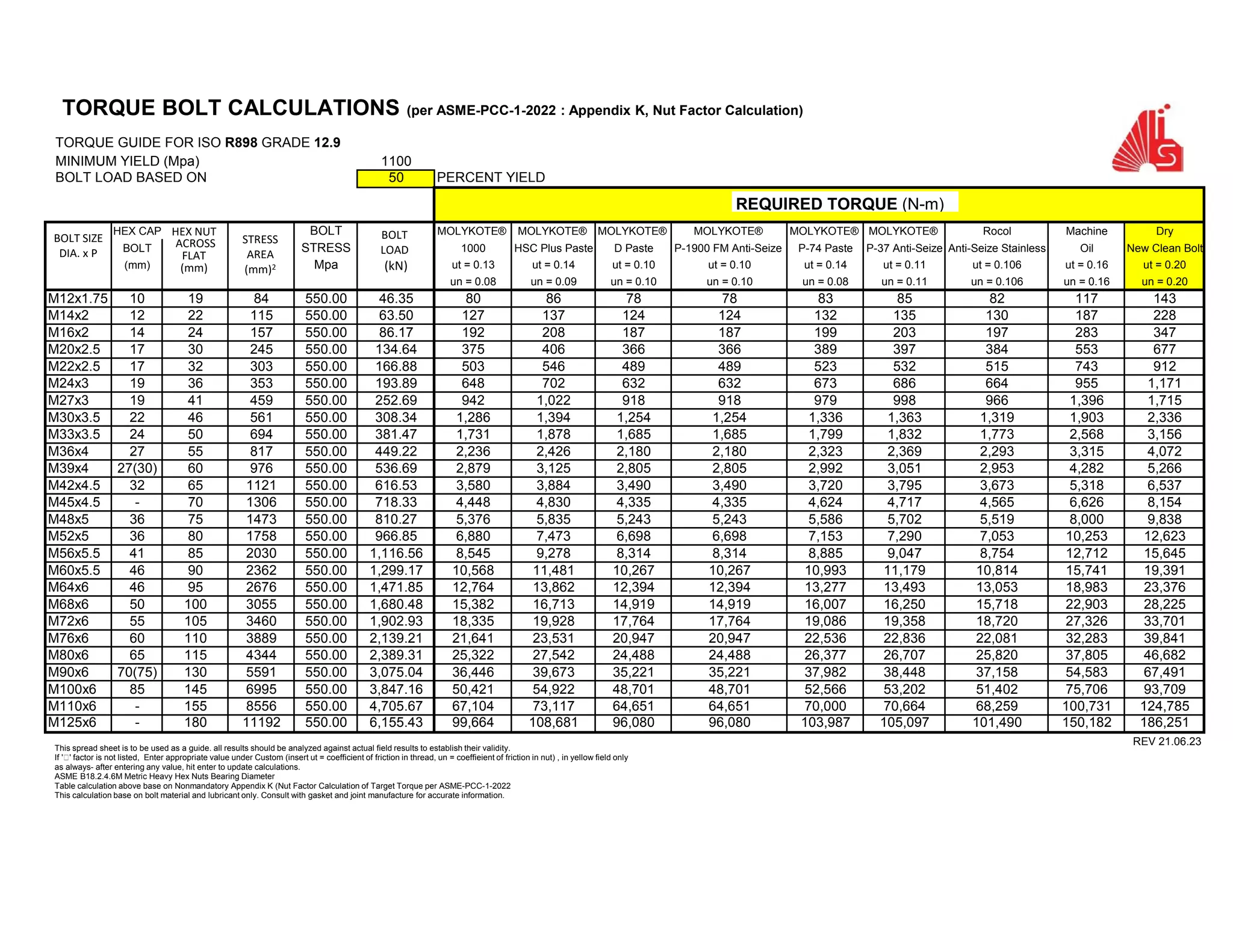

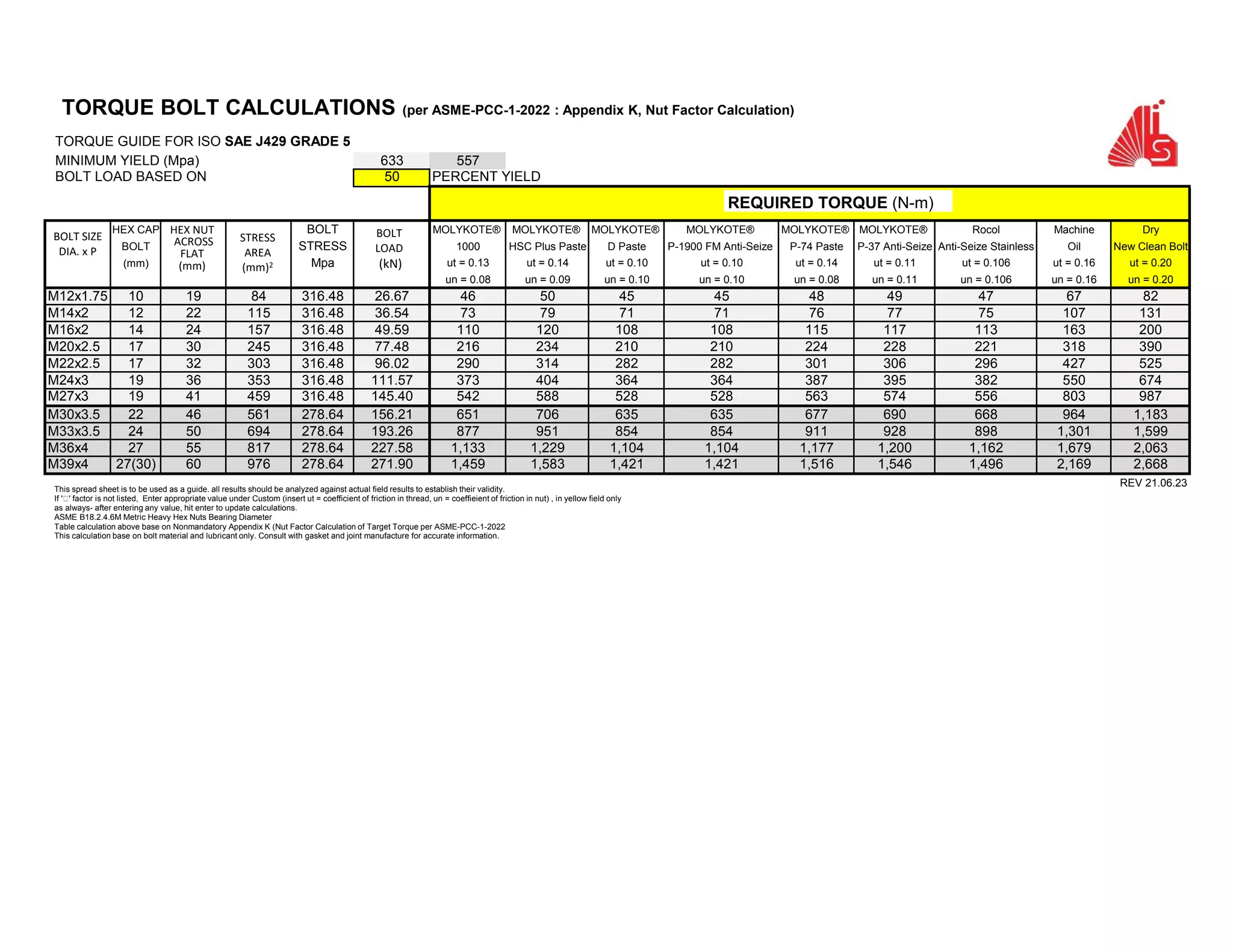

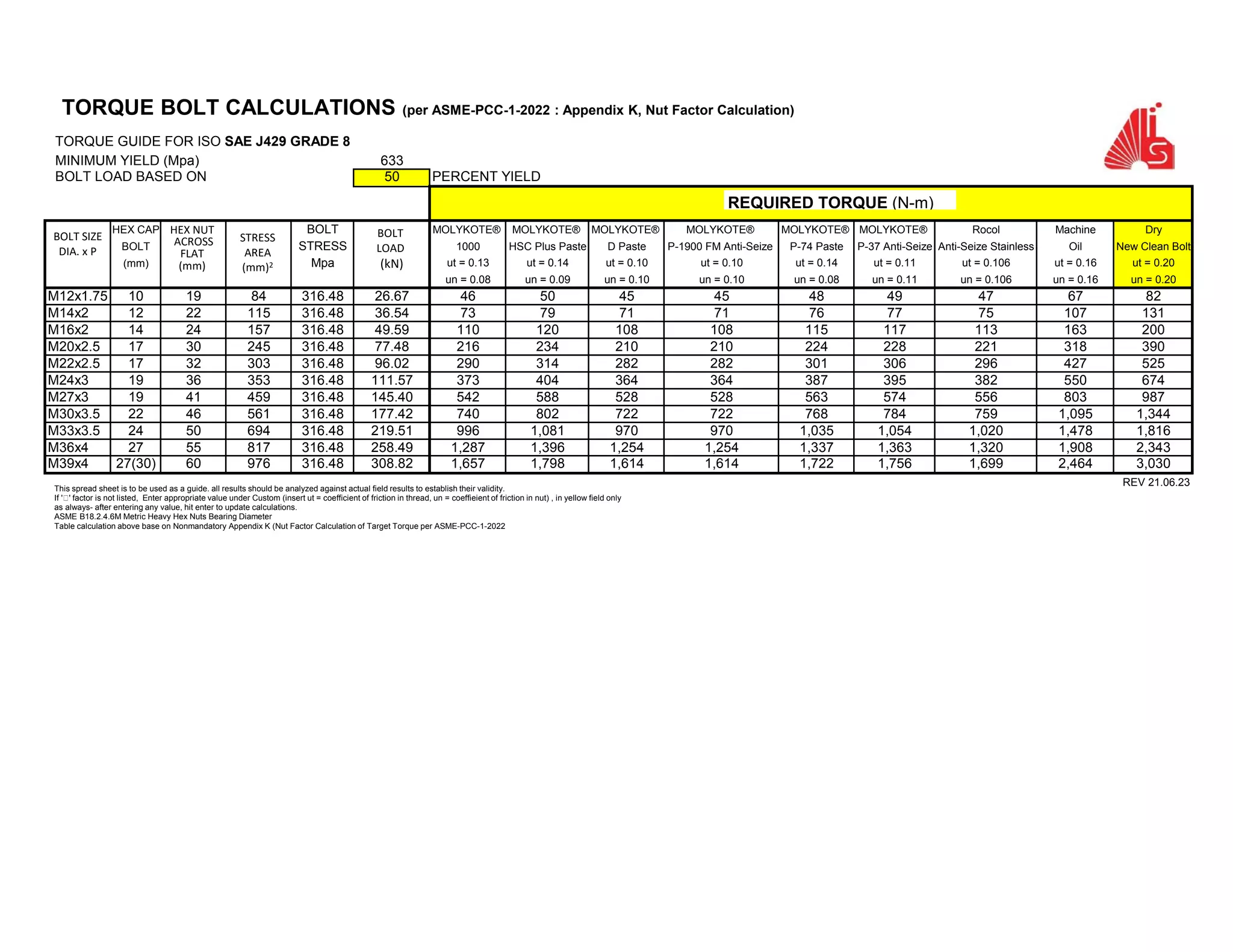

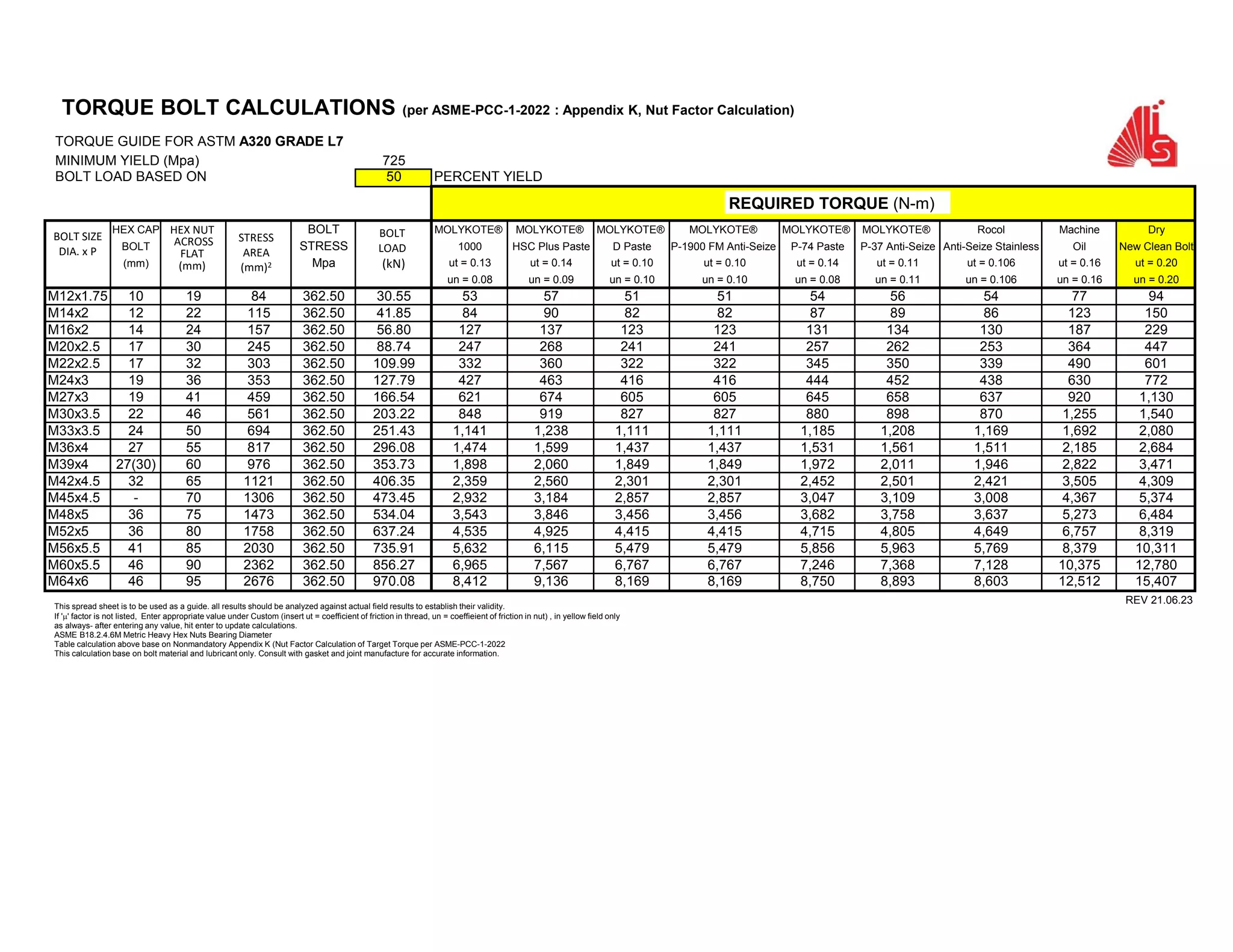

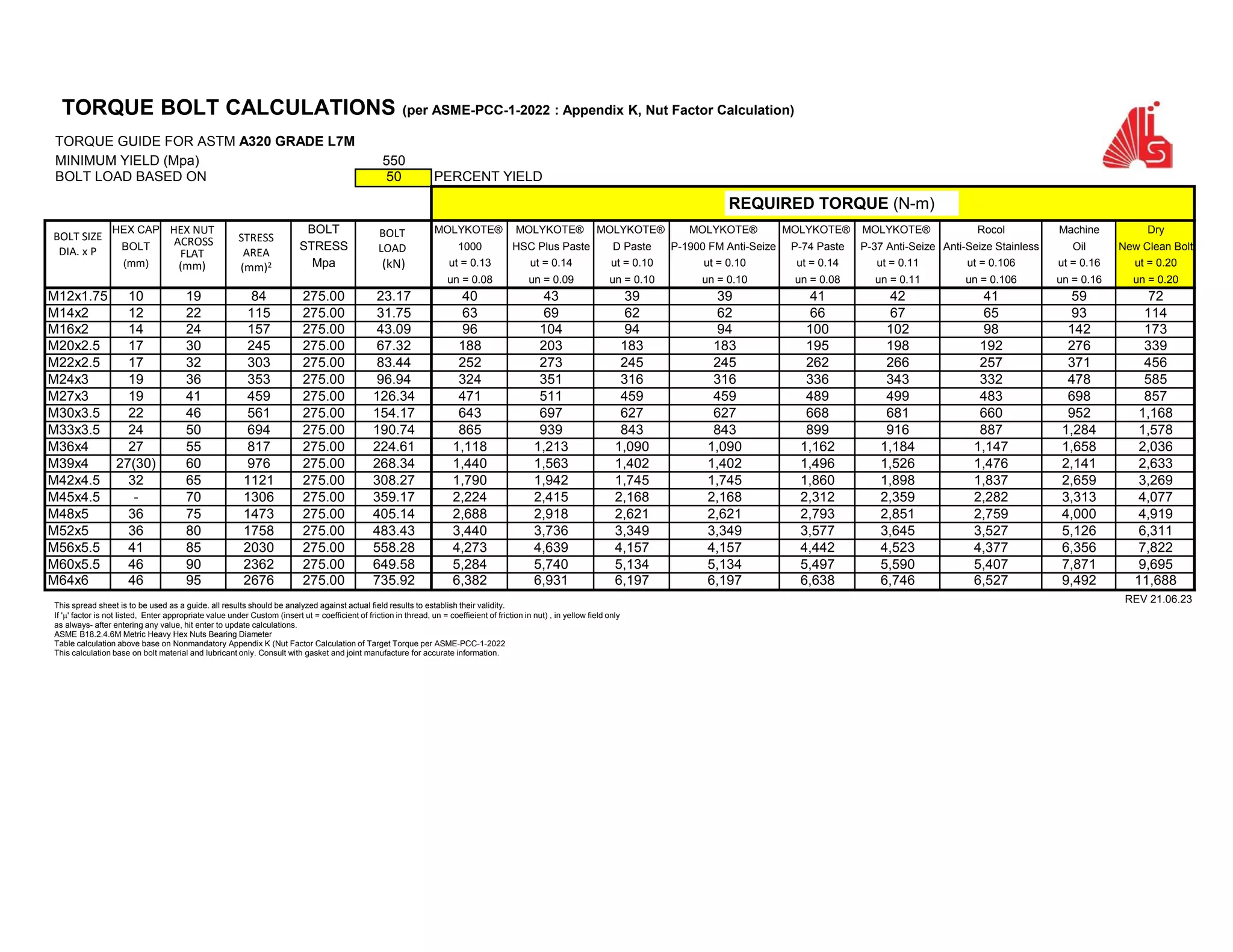

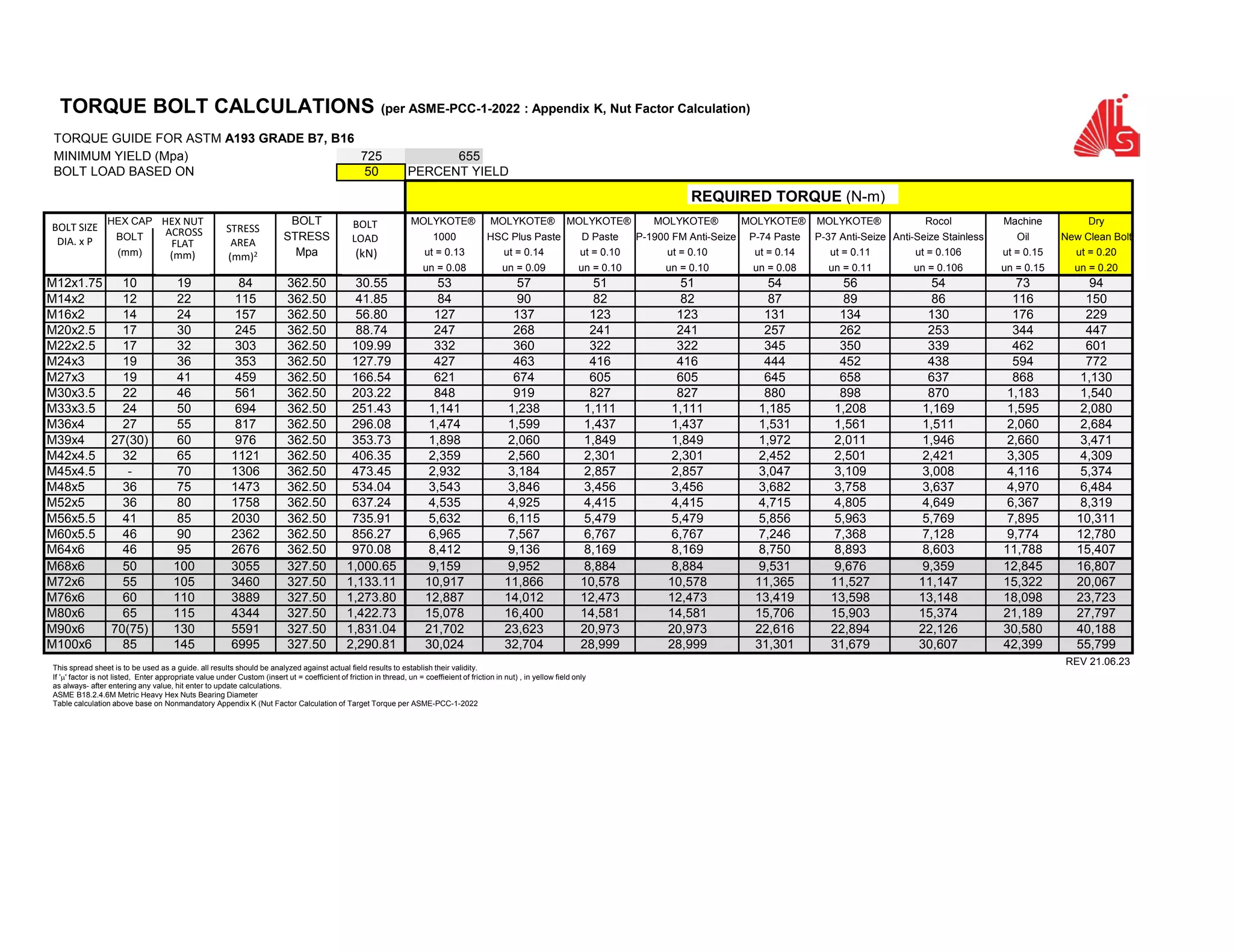

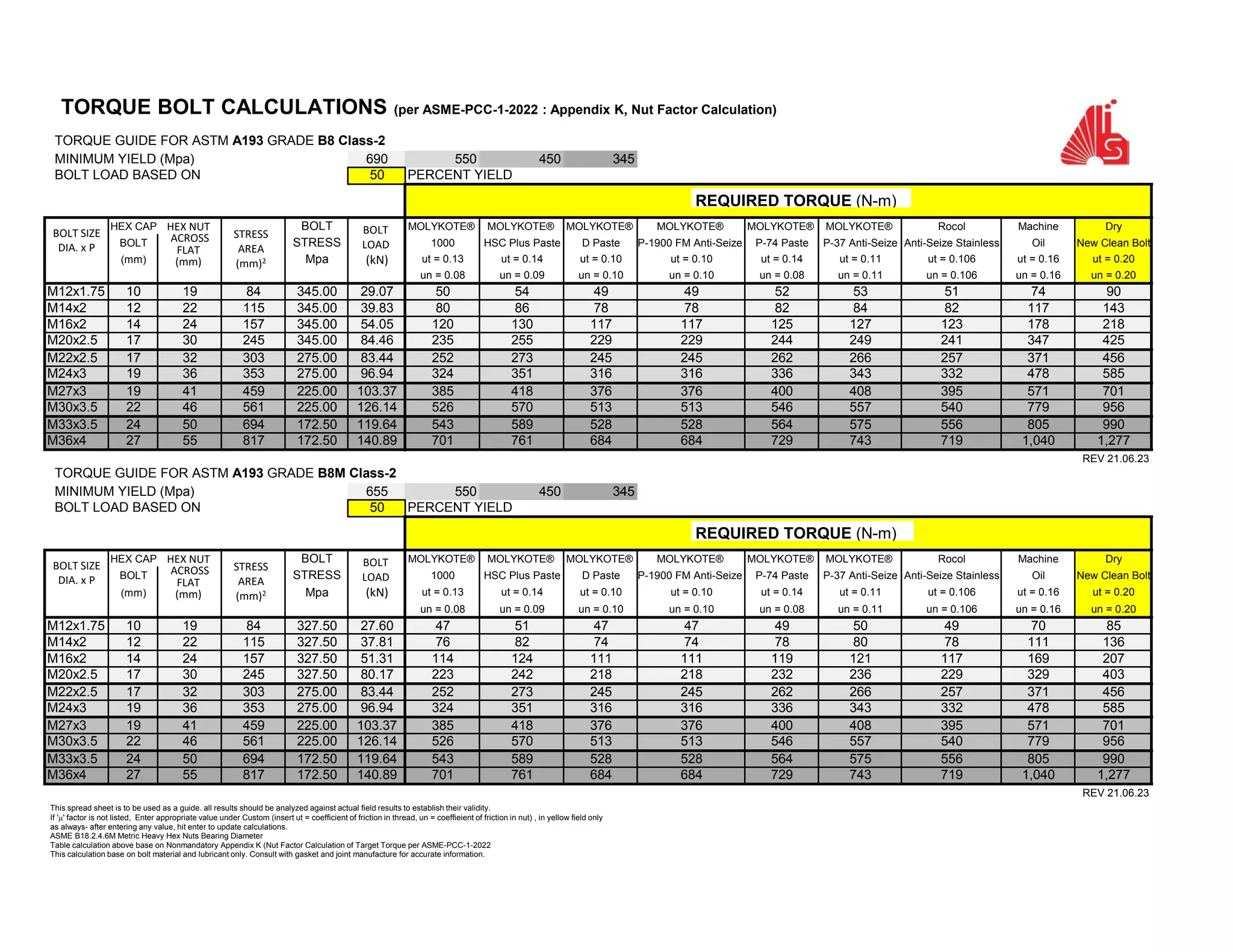

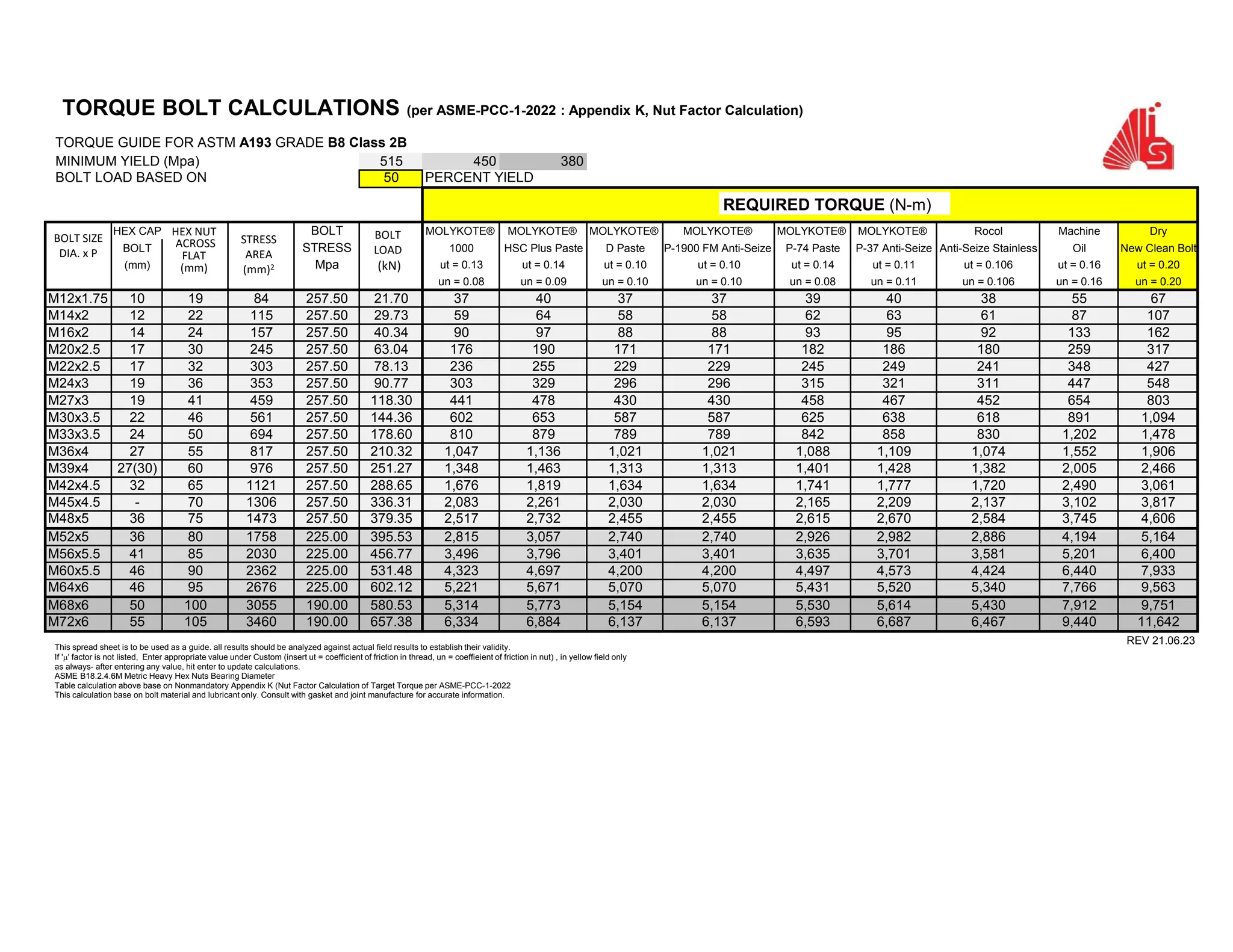

The document provides information on bolt stress, pressure, length, and diameter conversion factors. It includes a table with specifications for various bolt sizes including diameter, length, yield strength, torque values, and references. It also details calculations for determining bolt load and torque values based on factors like bolt material, lubricant used, and other specifications.