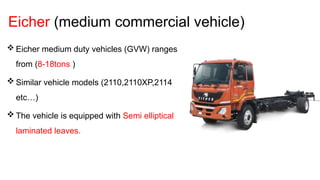

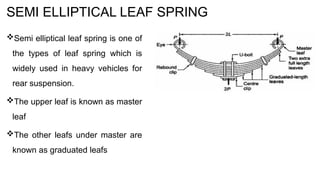

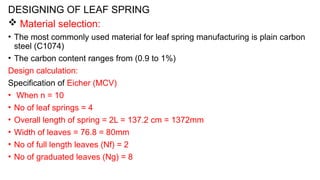

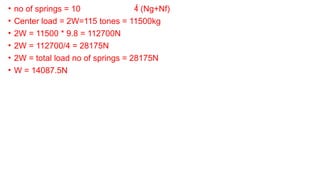

The document discusses the design and analysis of a semi-elliptic leaf spring used in Eicher medium commercial vehicles, detailing its structure, function, and advantages. Leaf springs are crucial for supporting vehicle weight, maintaining tire grip, and ensuring load stability. The document also covers types of leaf springs, material selection, and design calculations specific to Eicher's specifications.