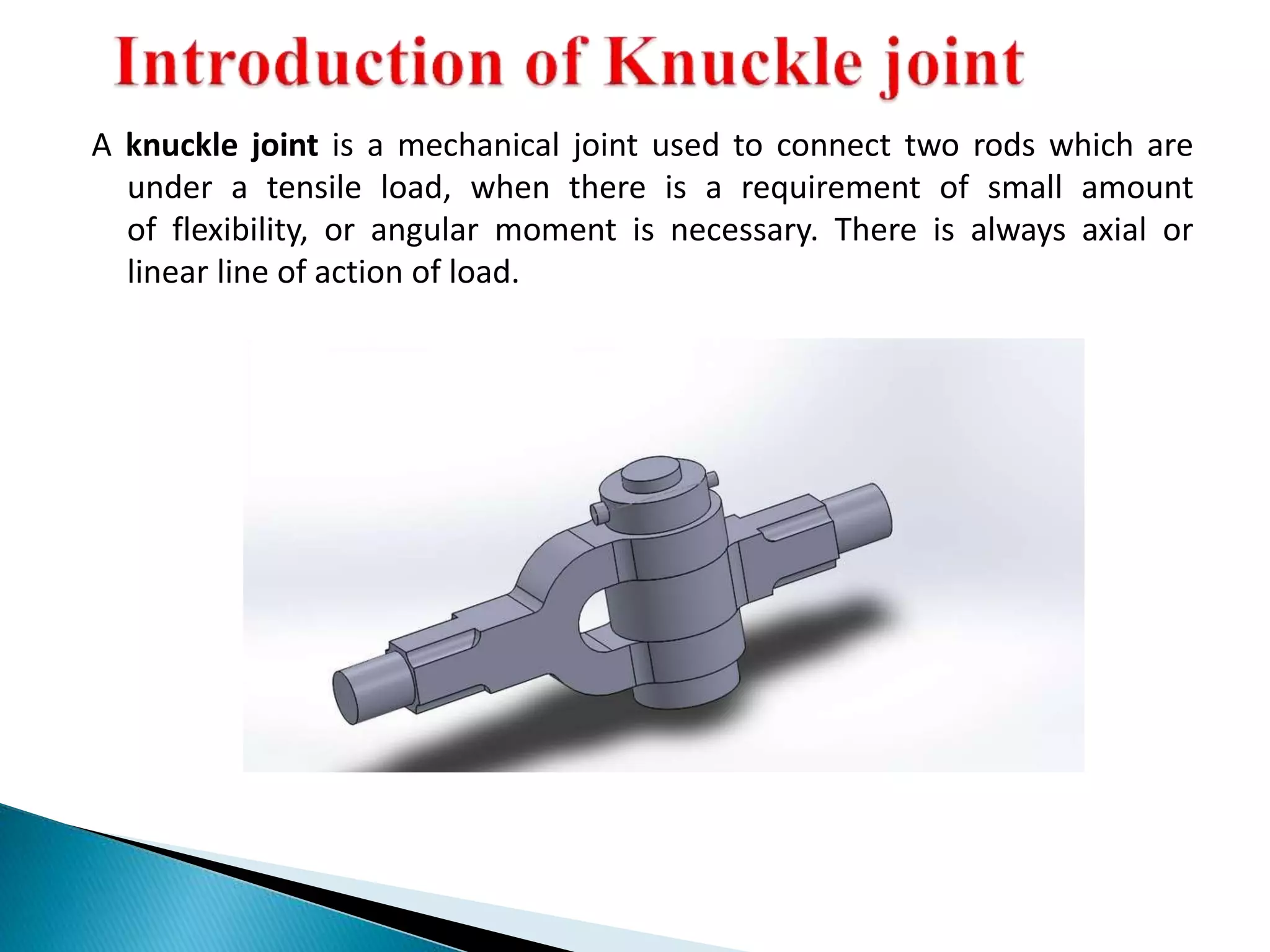

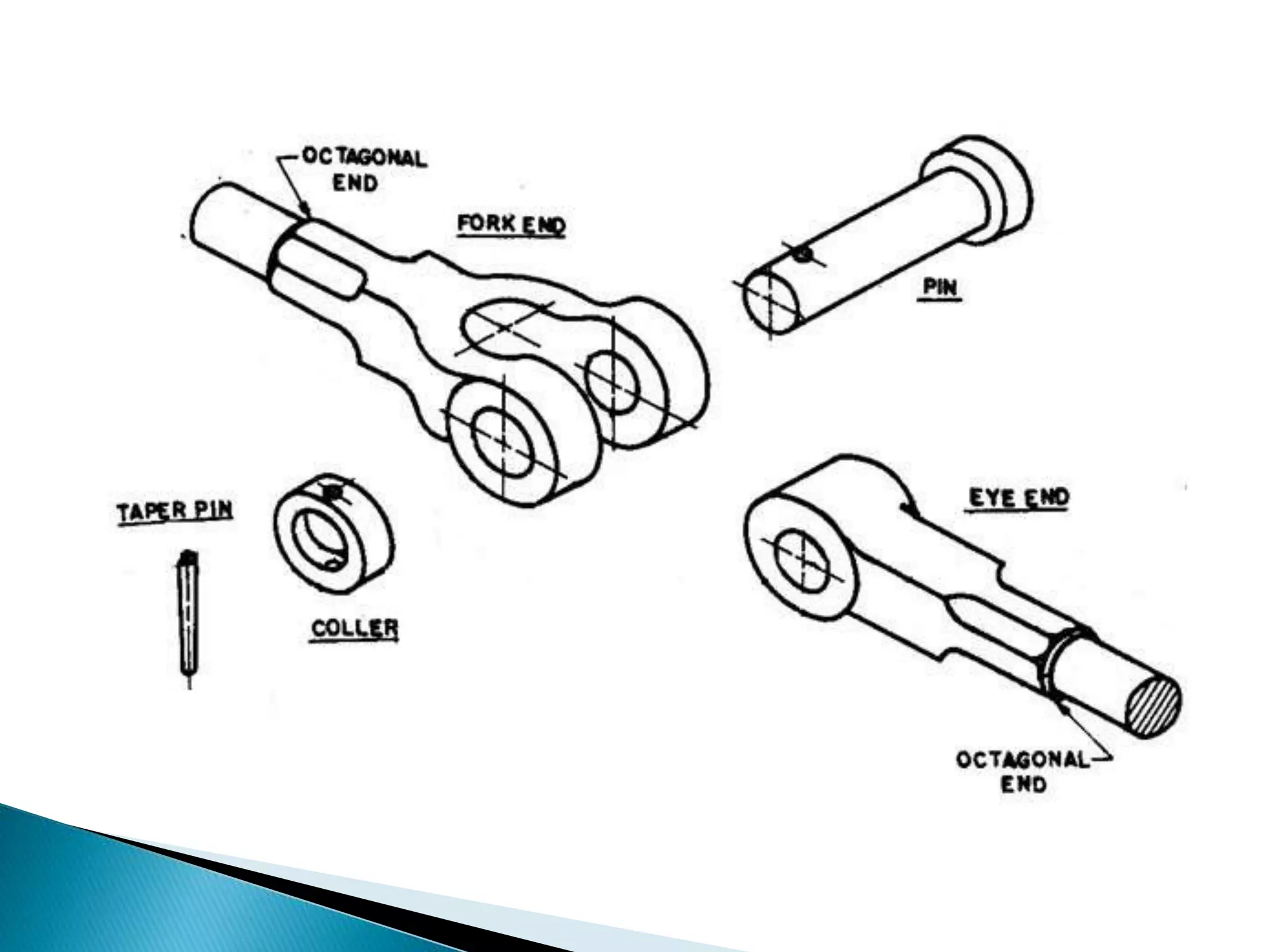

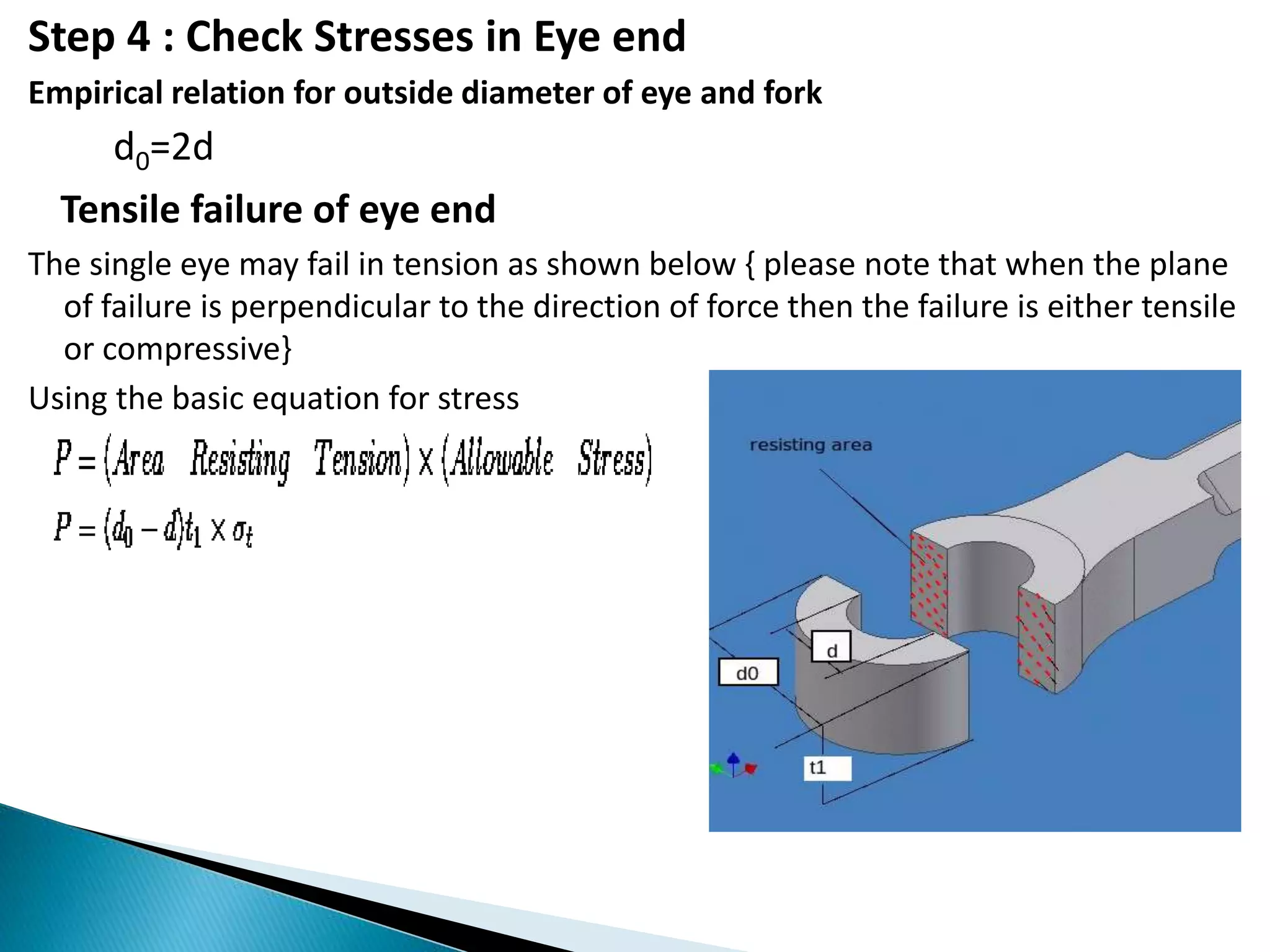

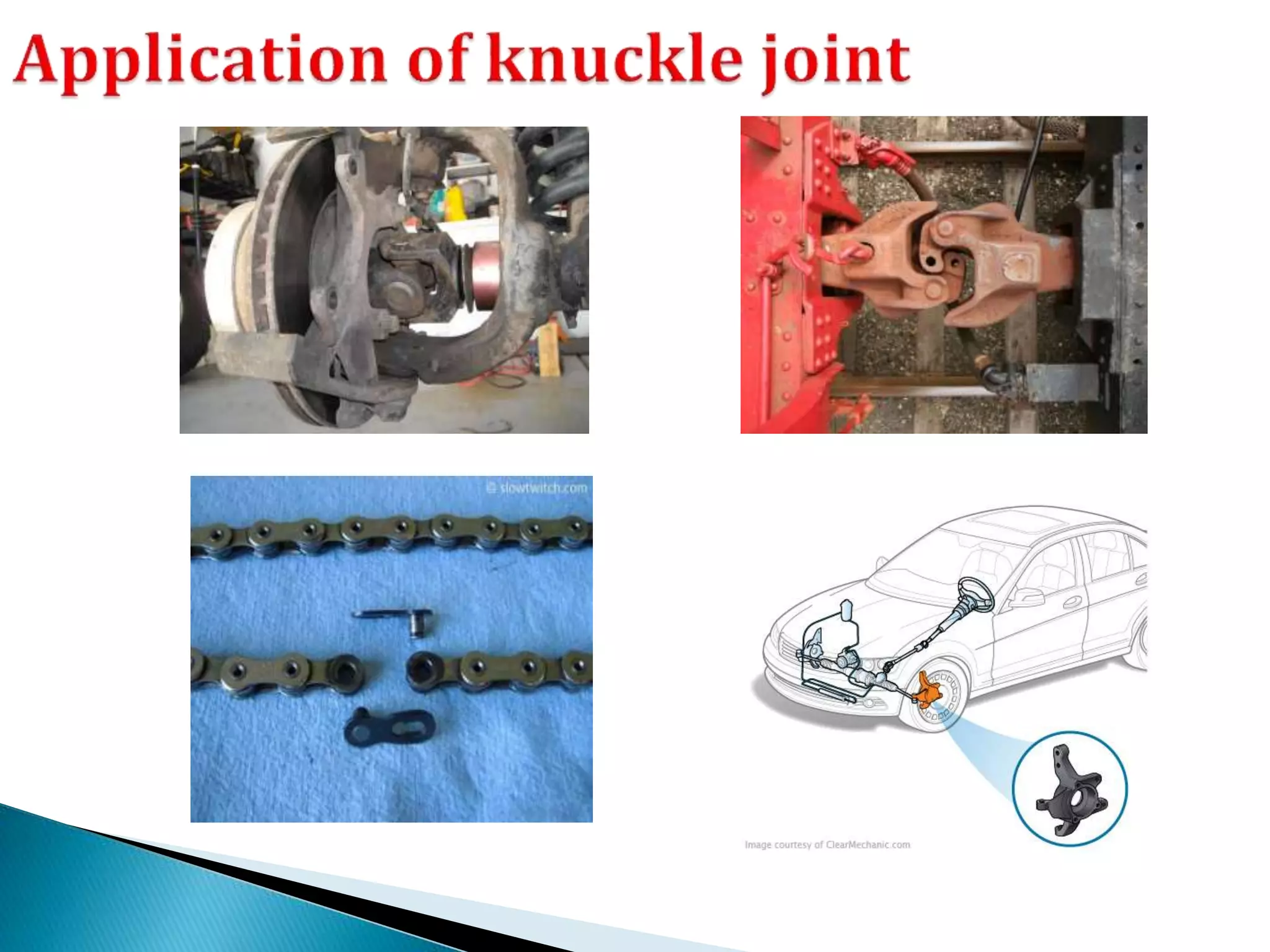

A knuckle joint connects two rods under tension and allows for small angular movements. It consists of eye ends, a forked end, a pin, and collar. The joint is designed by calculating rod diameters based on load, choosing eye/fork thicknesses and pin diameter based on empirical relations, and checking stresses do not exceed allowable values for tension, shear, and crushing. Knuckle joints can withstand tensile loads, are rigid but flexible, and easy to manufacture but cannot handle compression or multi-plane movements.