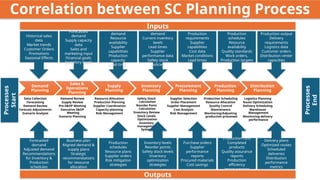

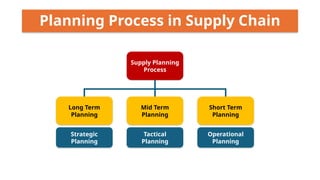

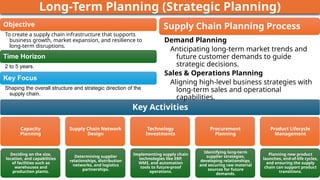

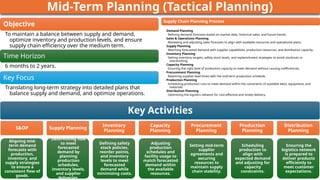

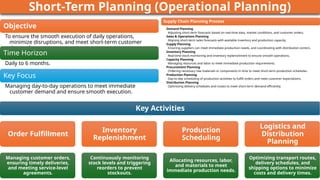

The document outlines the demand planning process within the supply chain, detailing various planning phases such as long-term, mid-term, and short-term planning. It emphasizes the need for alignment between demand forecasts and supply capabilities, covering aspects like inventory management, production scheduling, and strategic supplier relationships. Additionally, it highlights the overall objective of creating a resilient supply chain infrastructure that effectively responds to market demands and optimizes operational efficiency.