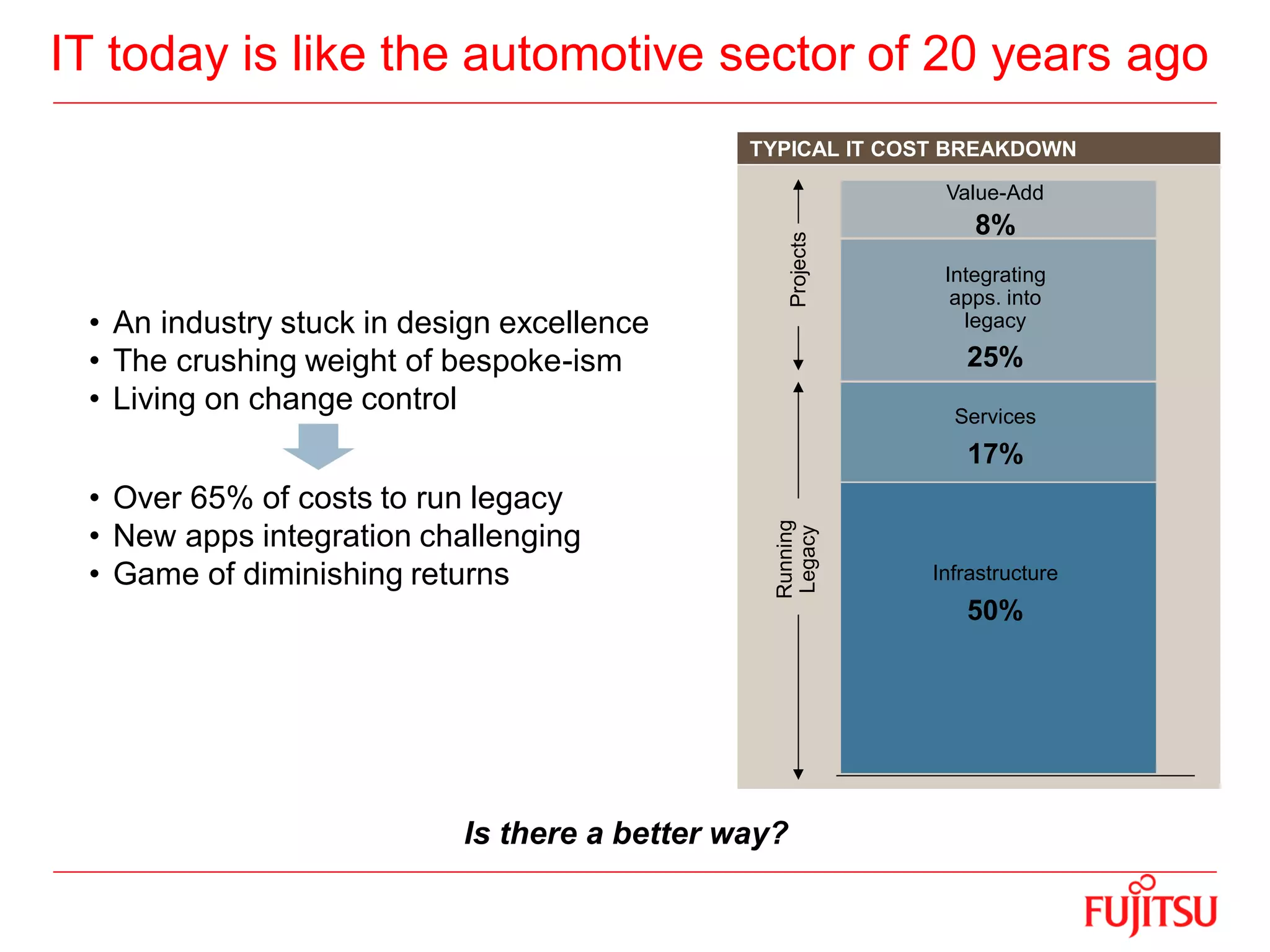

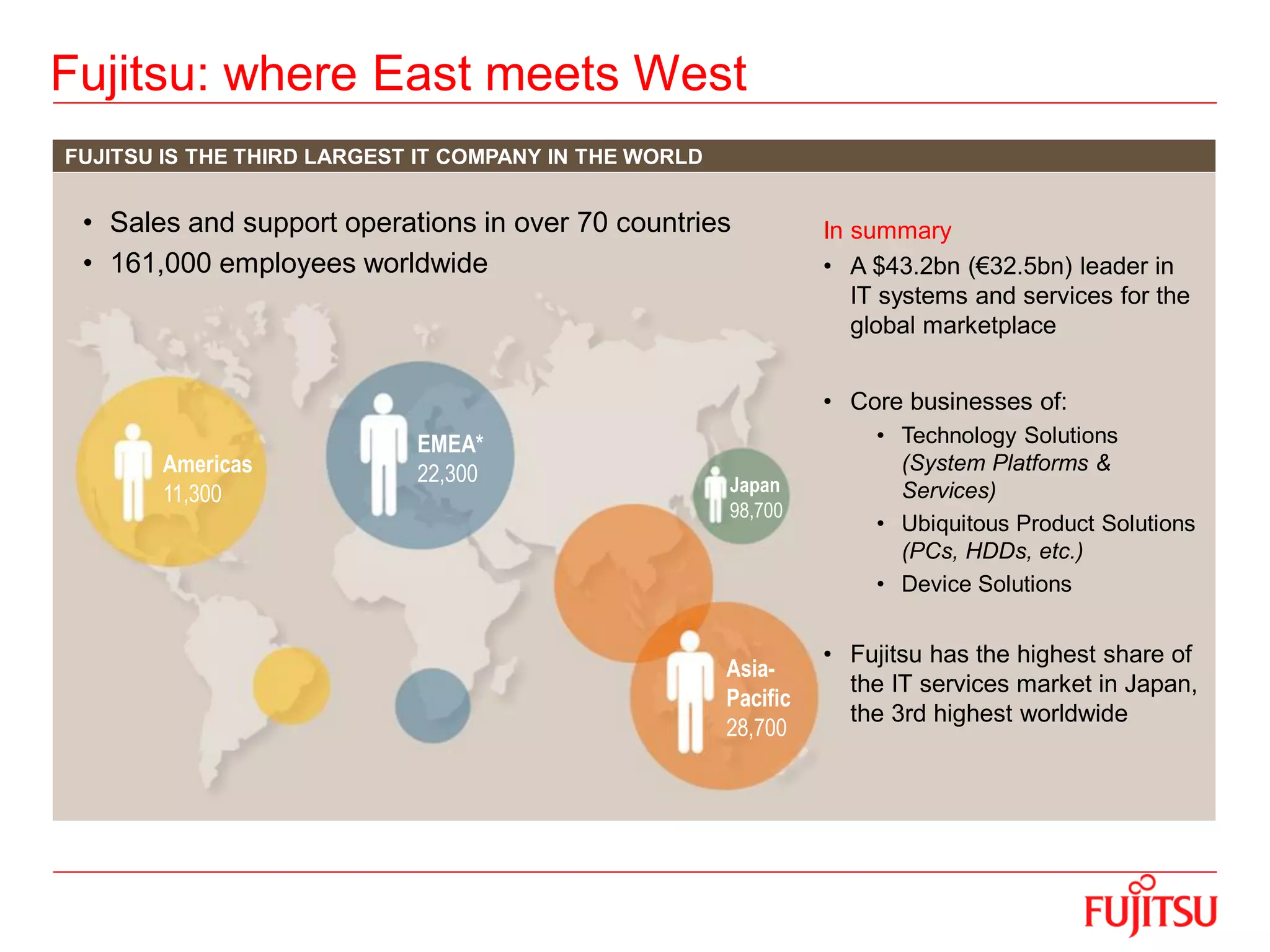

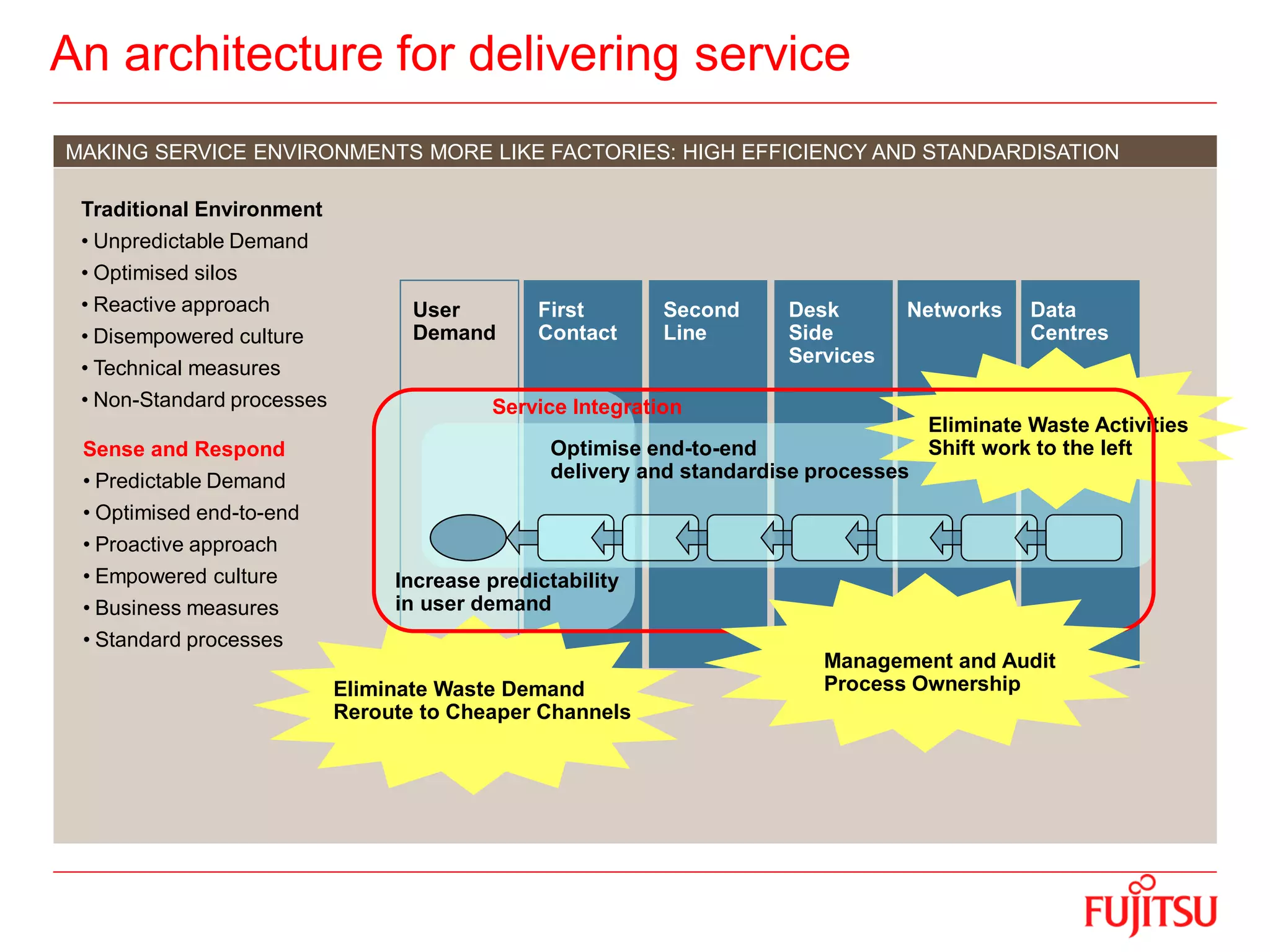

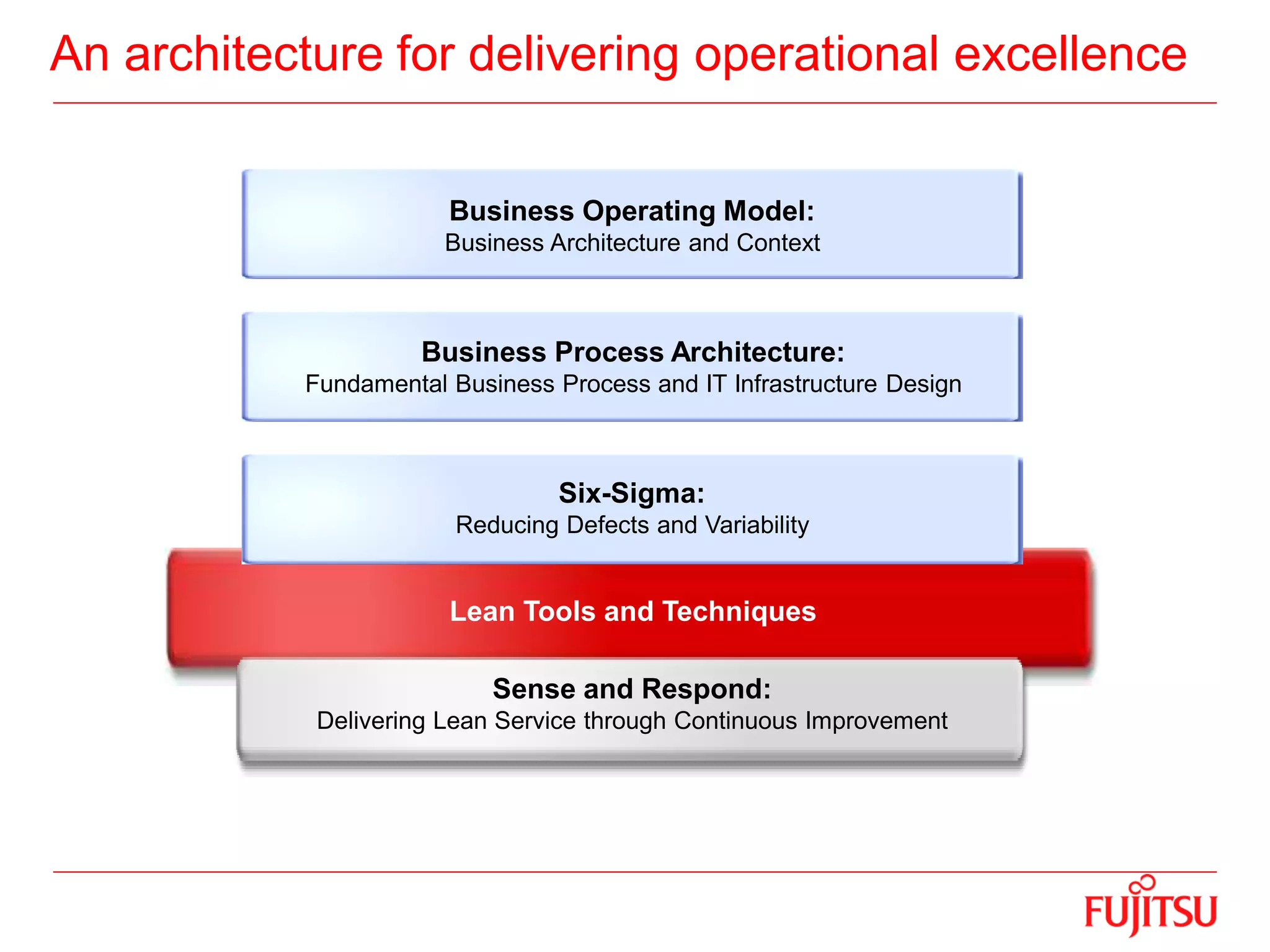

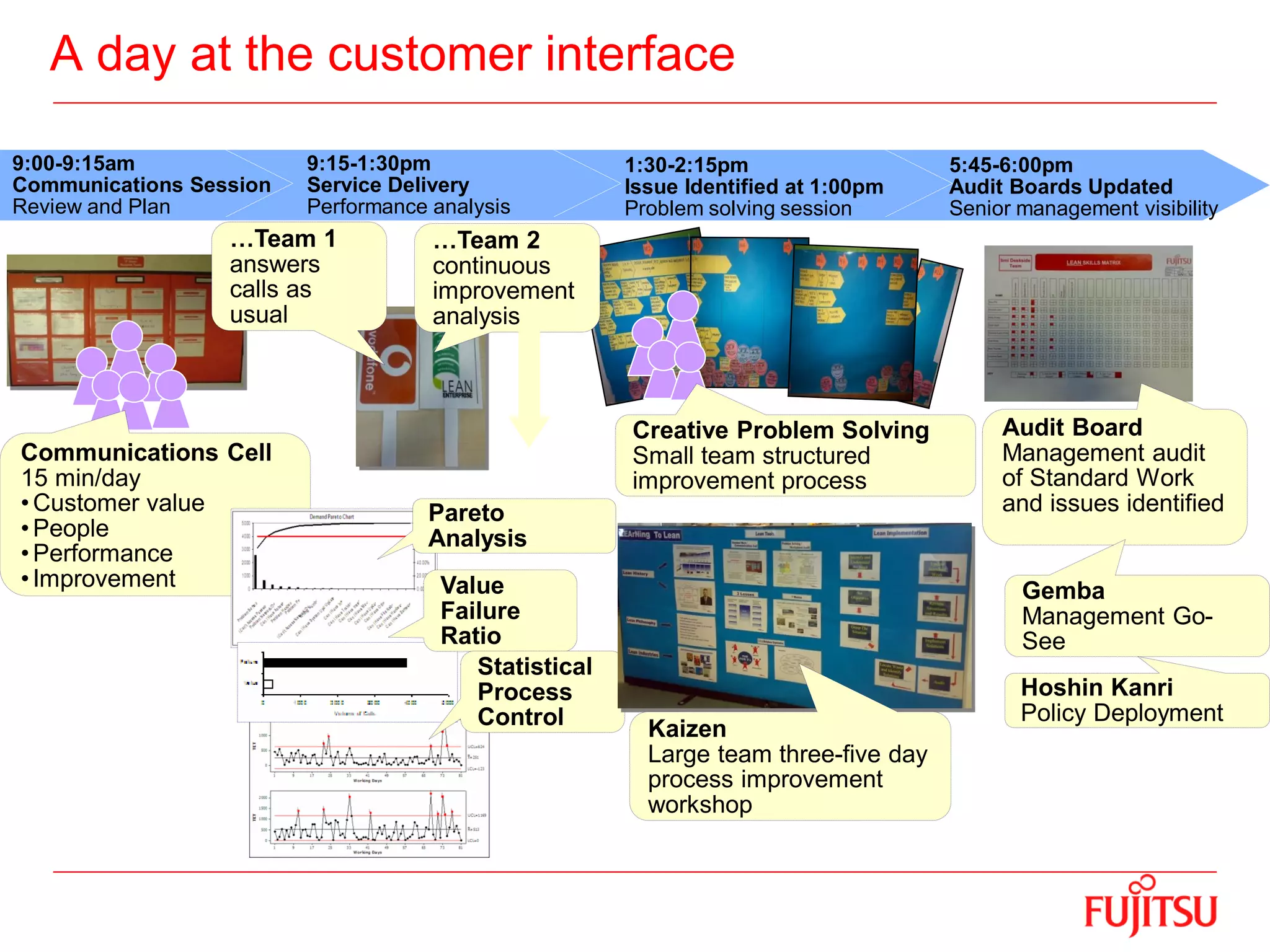

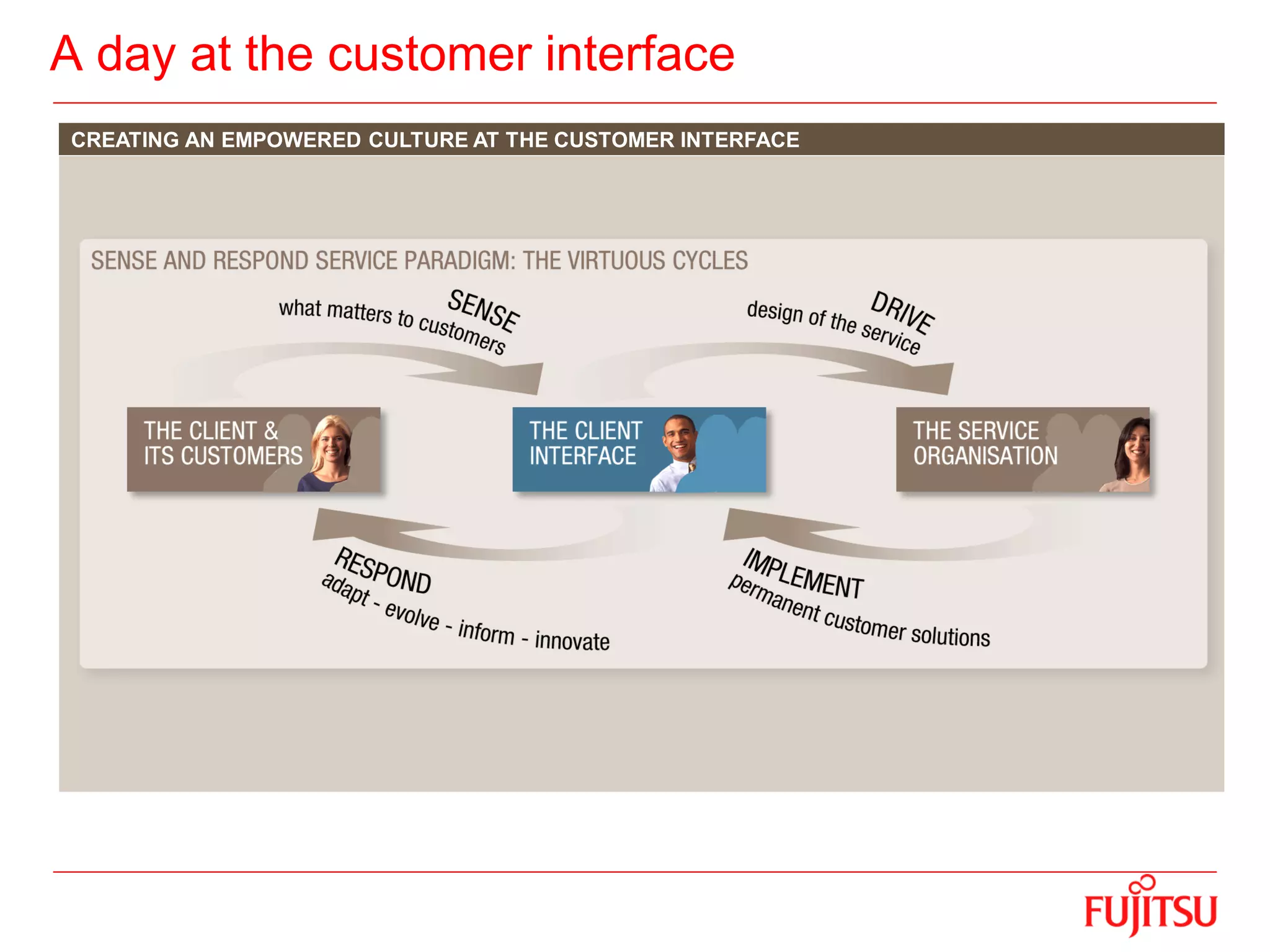

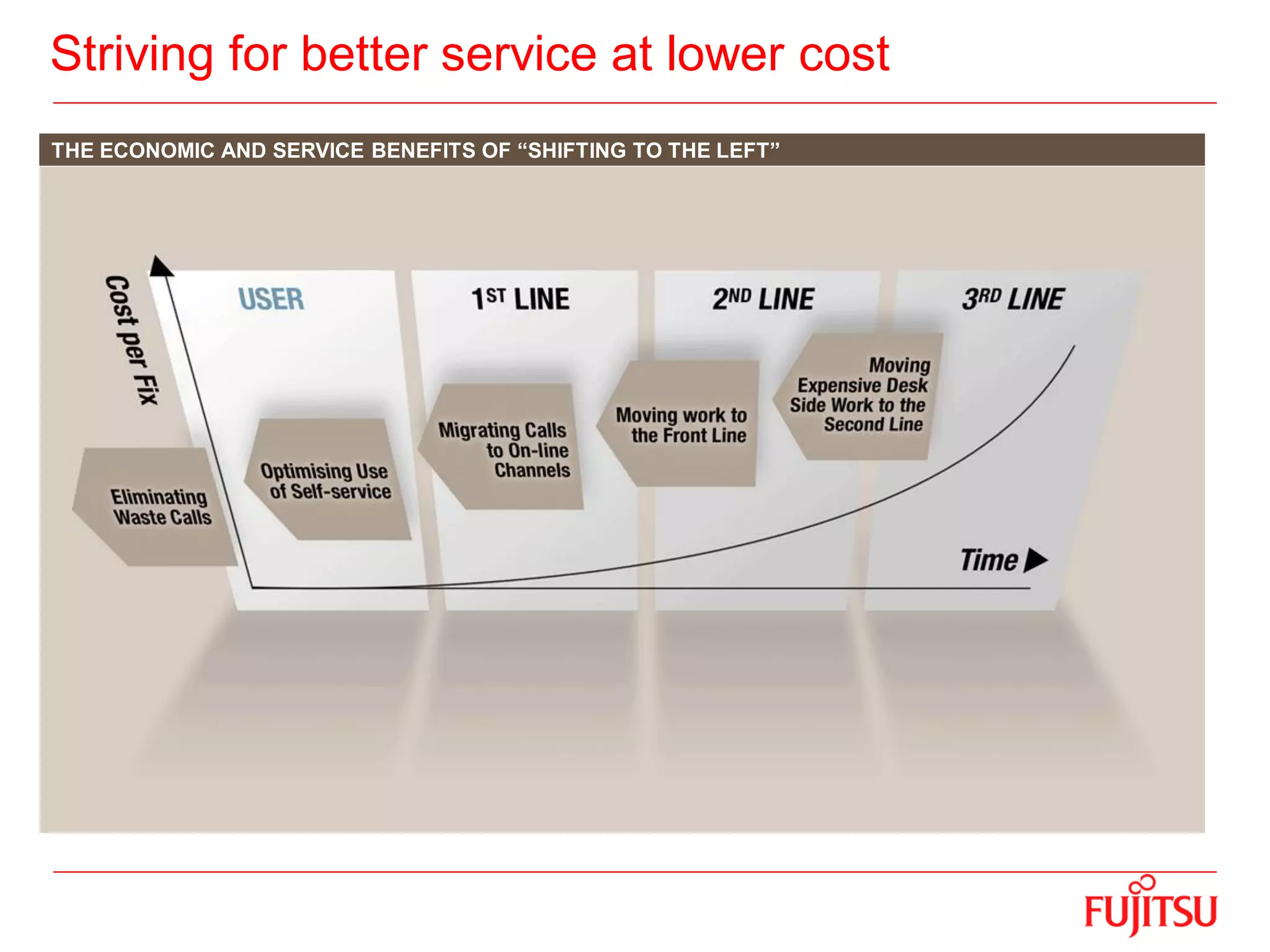

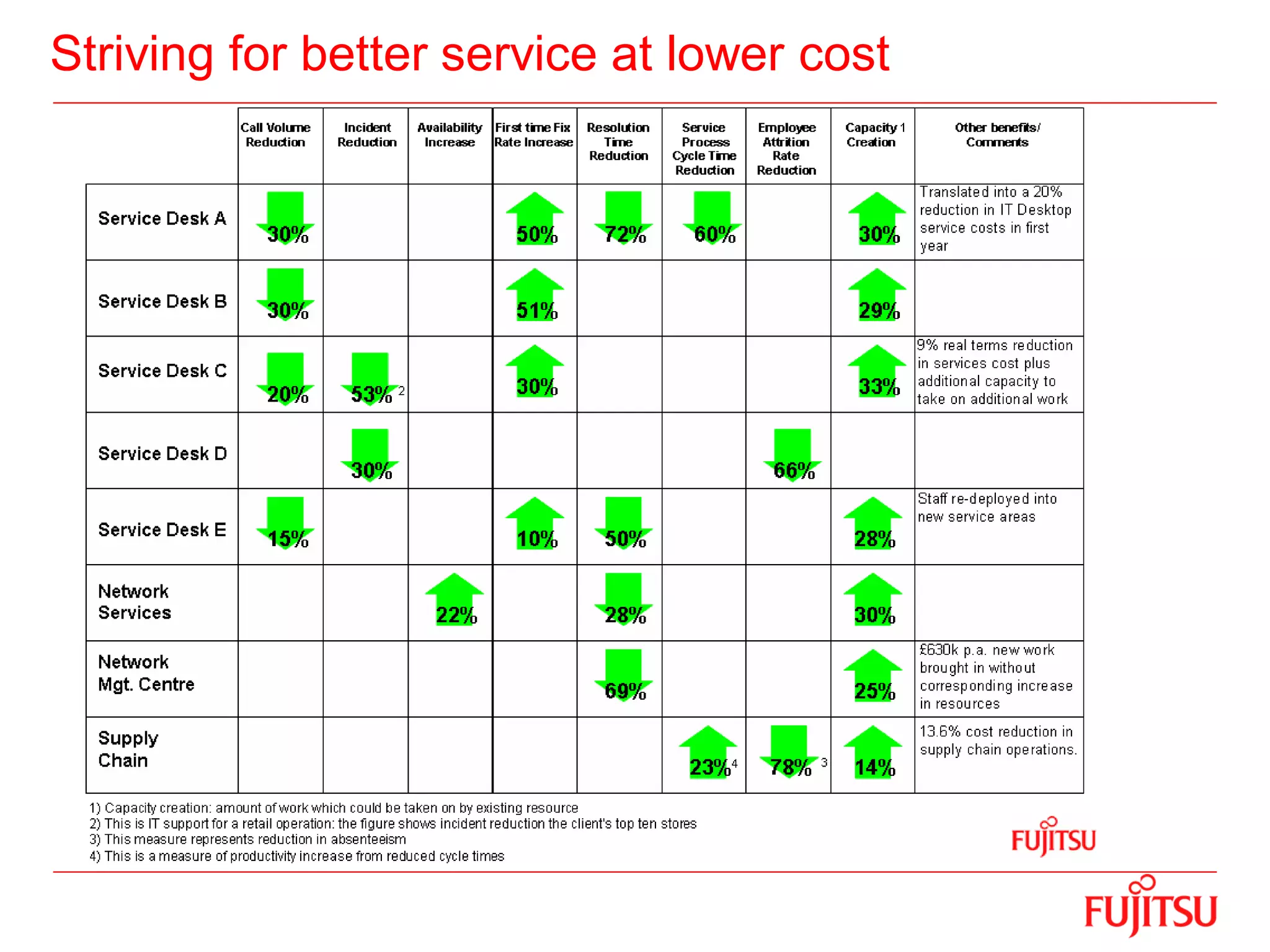

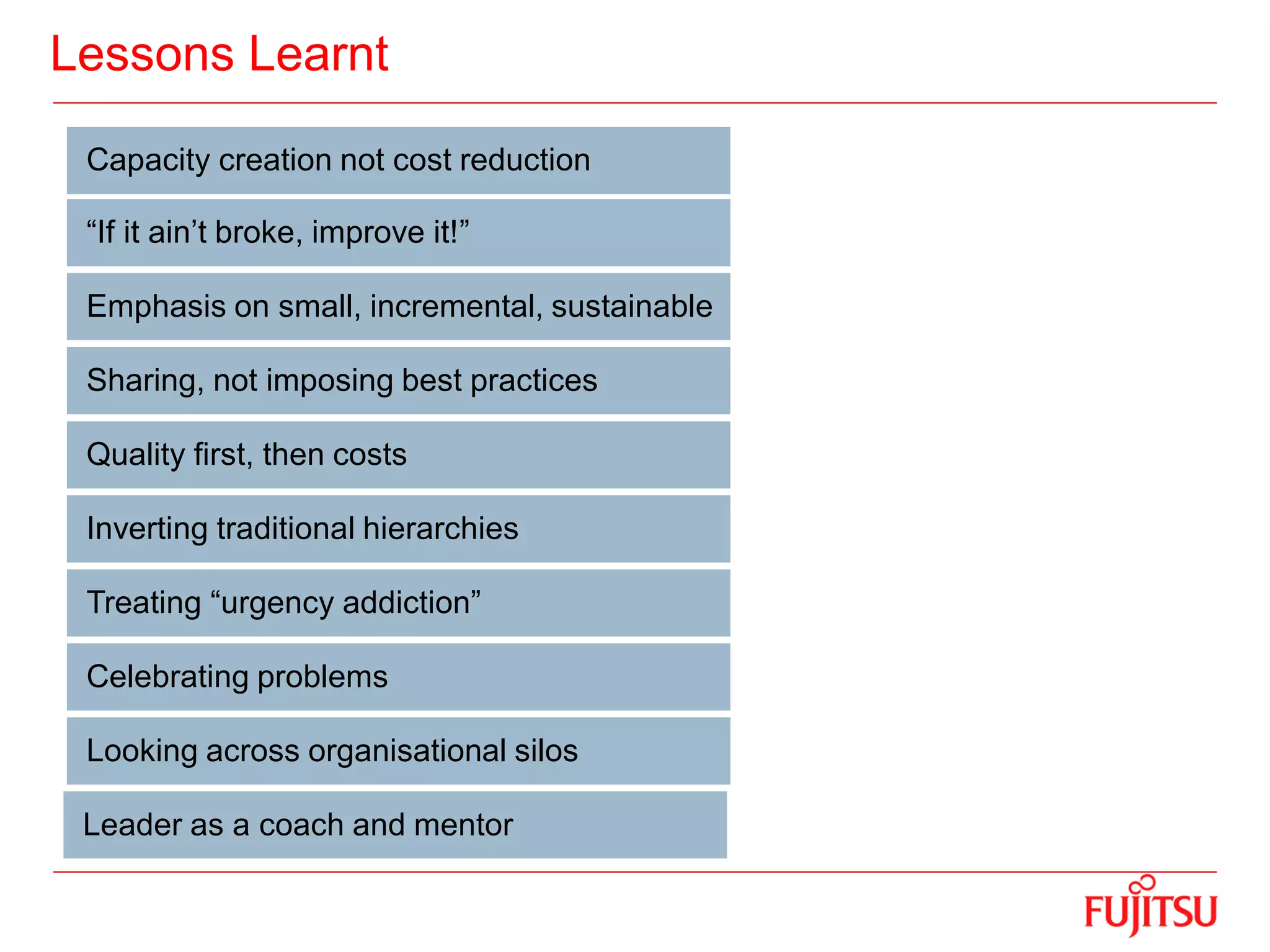

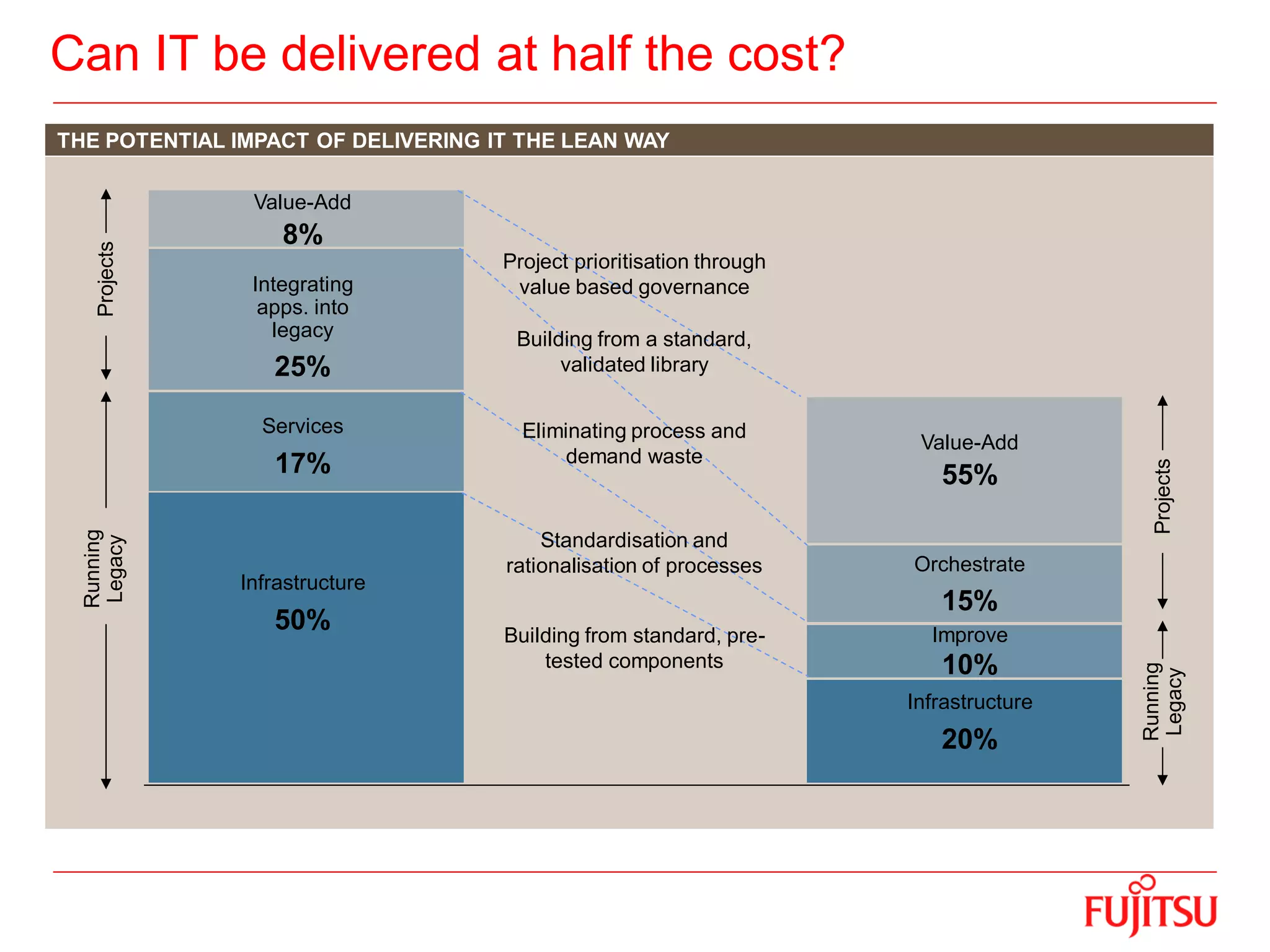

This document summarizes a presentation on delivering lean IT services through continuous improvement and standardization. It discusses how Fujitsu applies lean principles like reducing waste and standardizing components and processes. Currently, most IT costs go to running legacy systems and infrastructure, but Fujitsu's approach aims to shift work left through standardization, reduce demand waste, and prioritize projects based on value to increase the portion of spending adding value from just 8% to 55%. By optimizing end-to-end delivery and standardizing processes, the potential impact of delivering IT through lean principles could be to reduce costs by half.