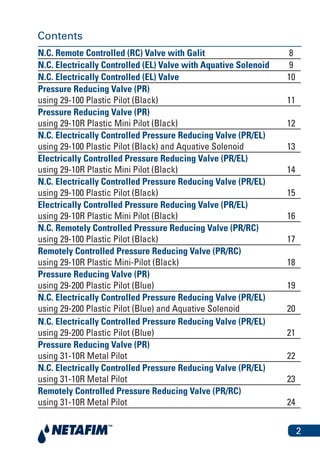

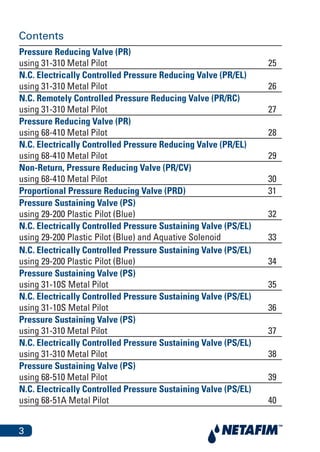

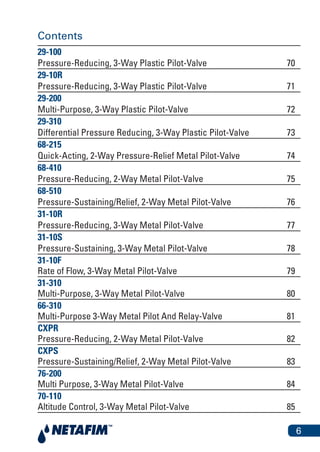

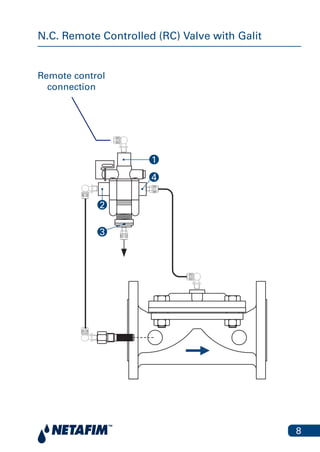

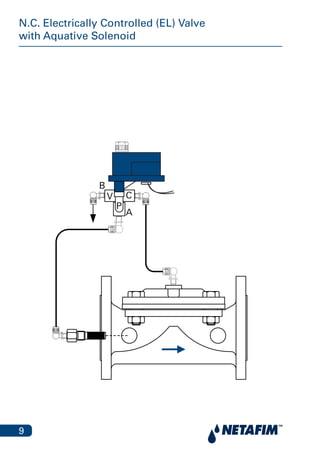

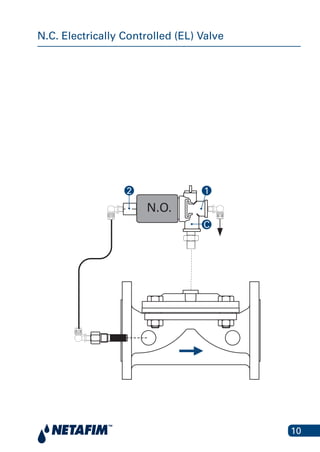

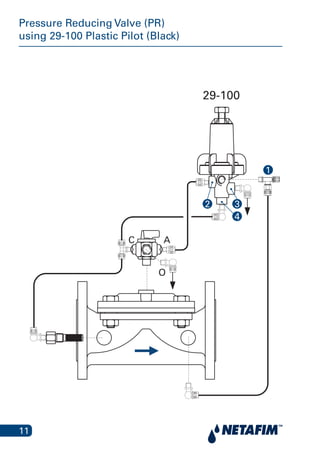

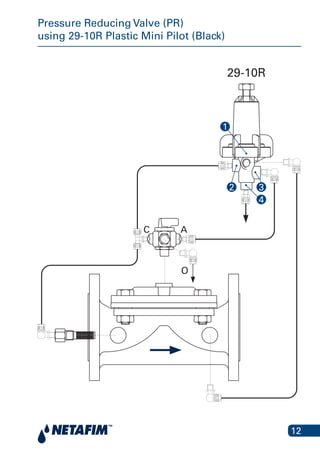

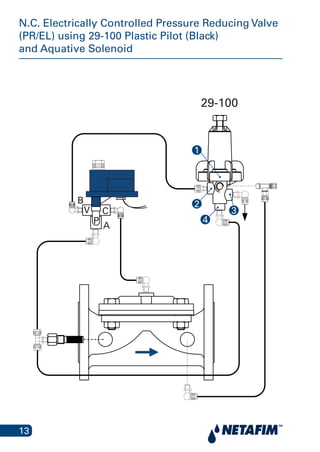

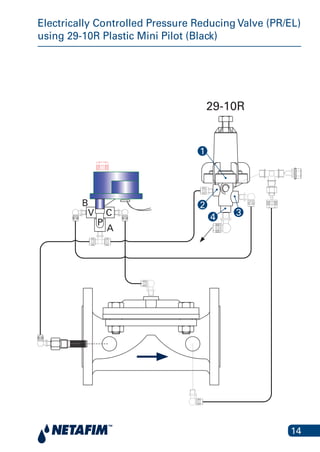

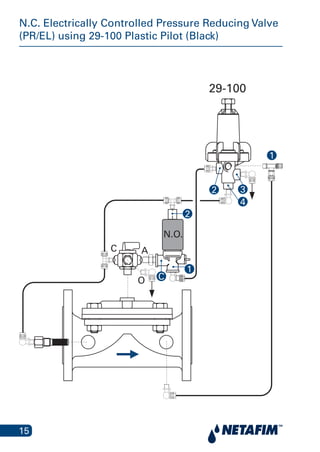

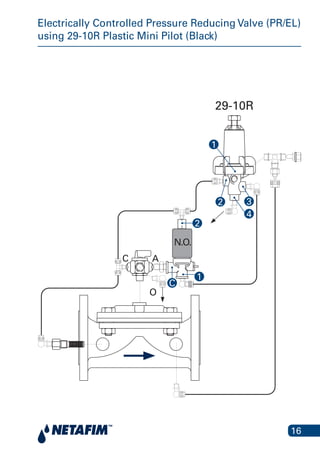

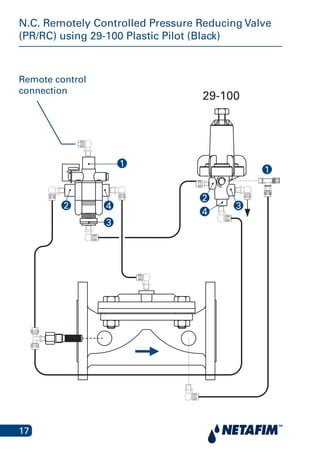

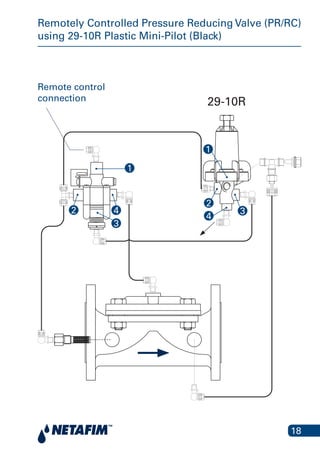

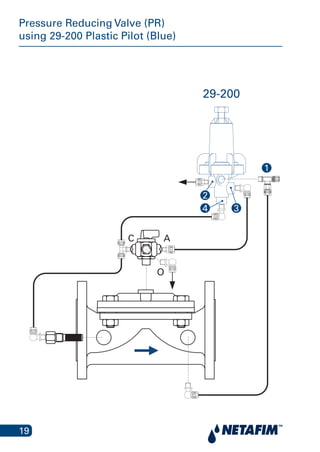

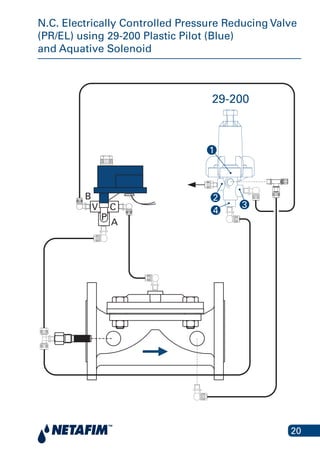

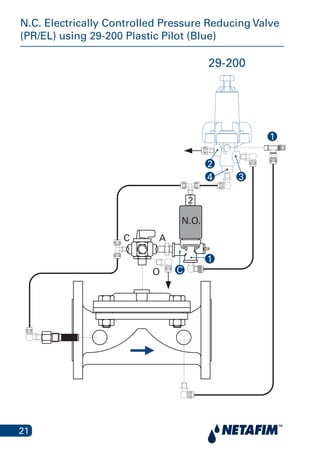

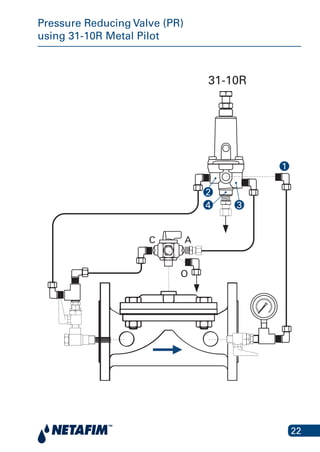

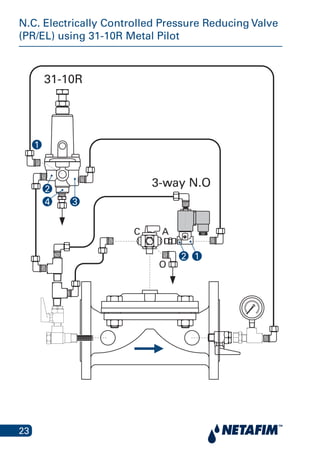

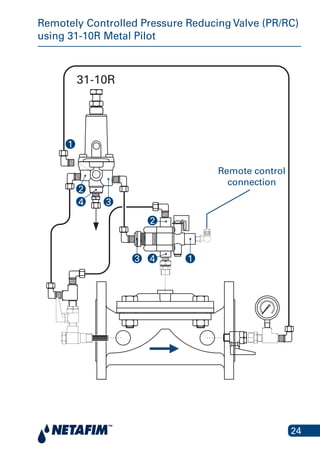

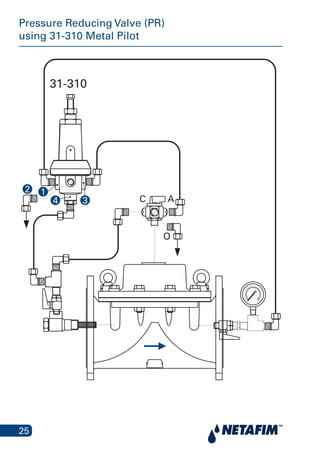

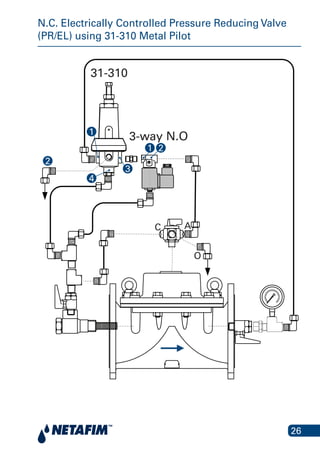

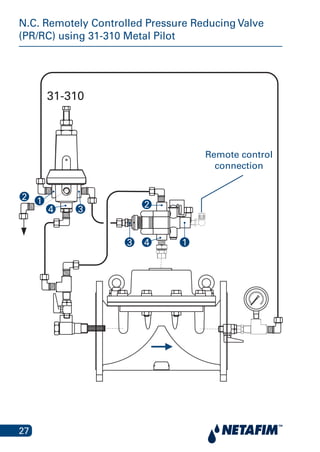

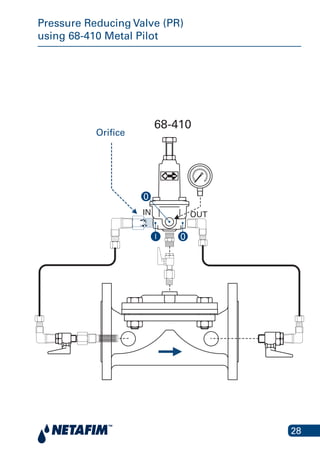

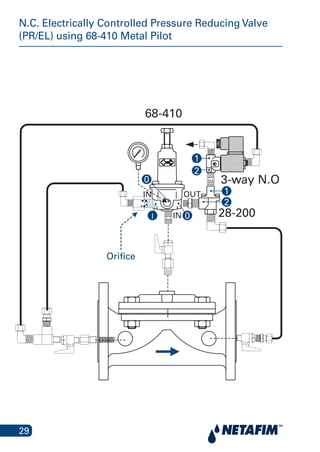

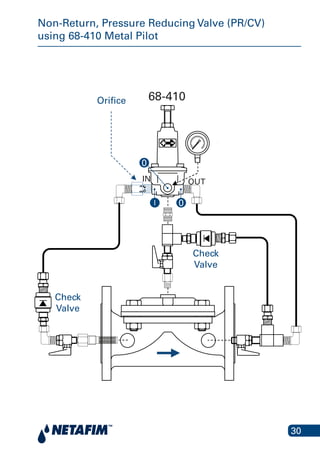

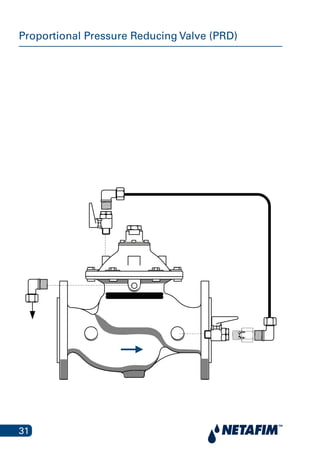

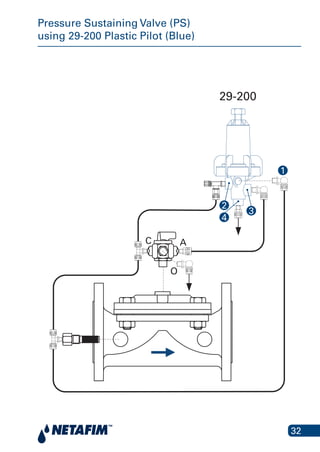

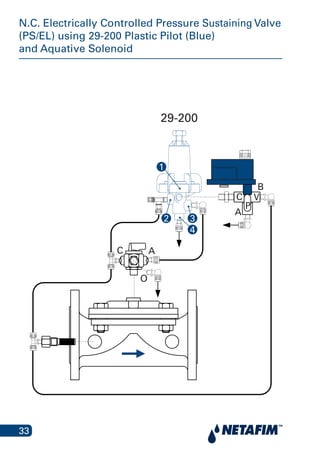

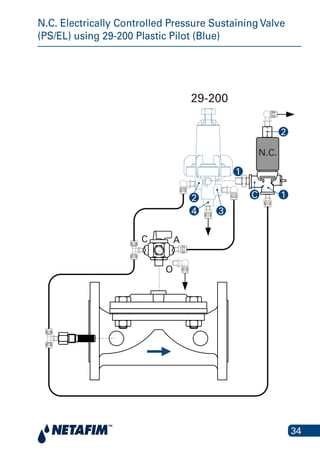

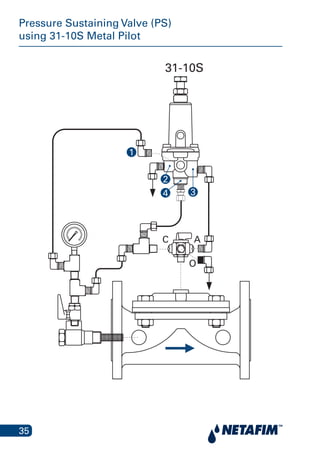

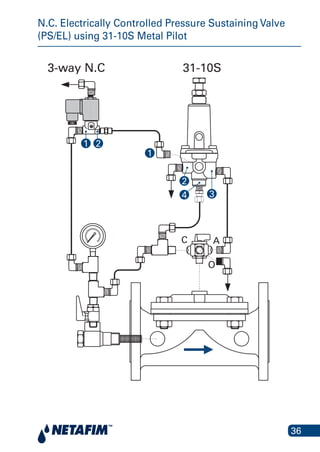

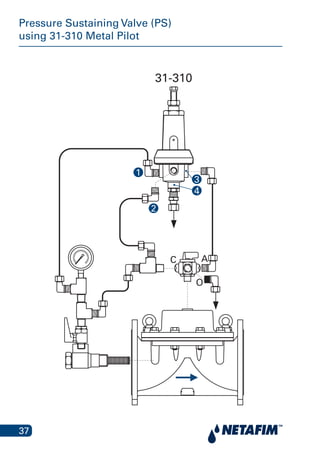

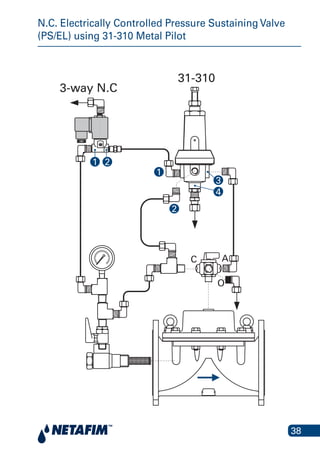

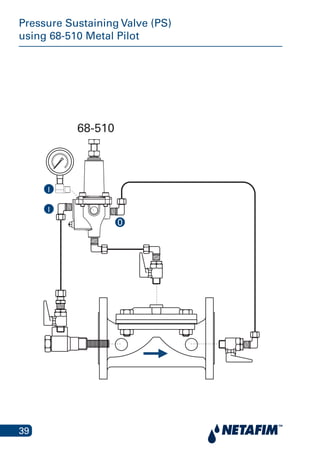

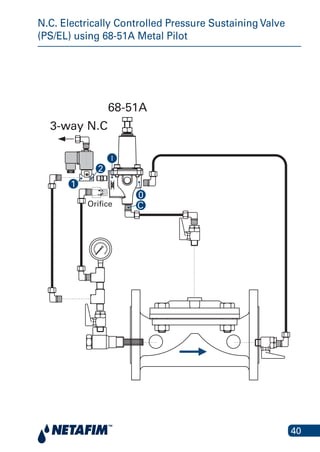

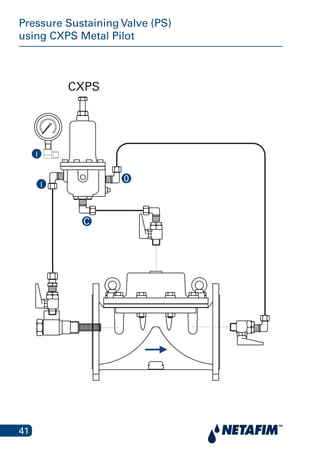

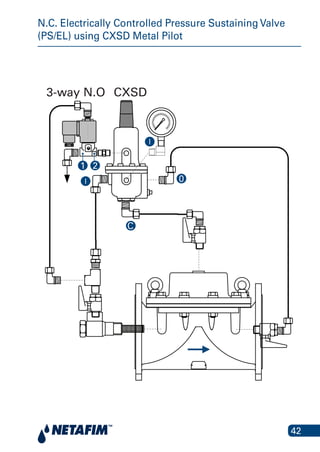

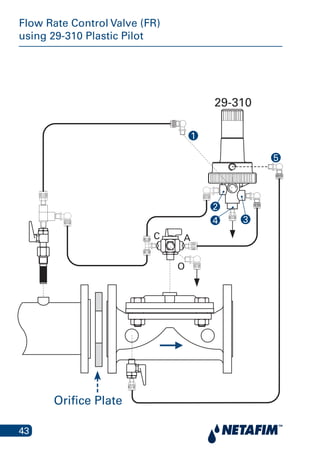

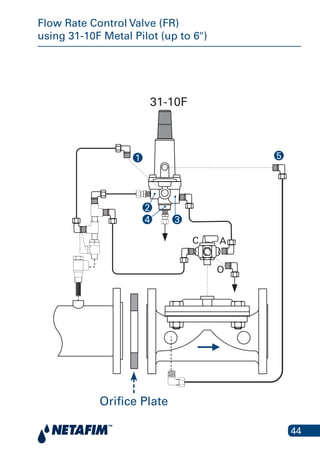

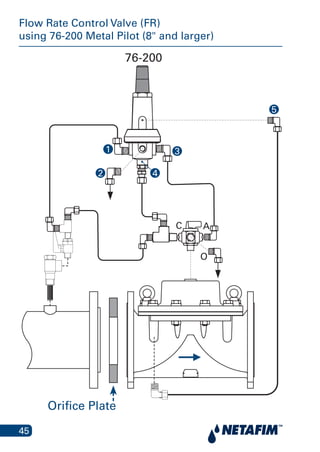

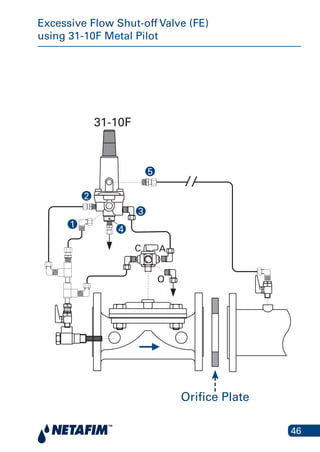

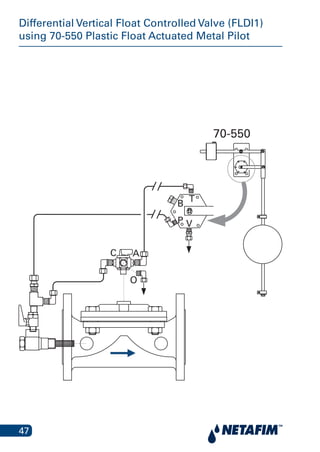

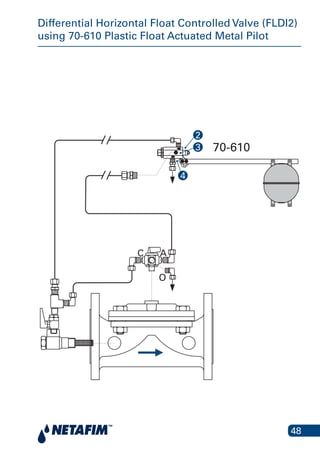

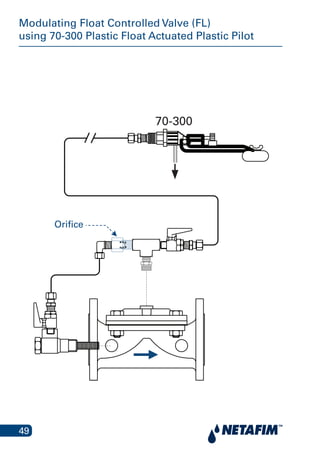

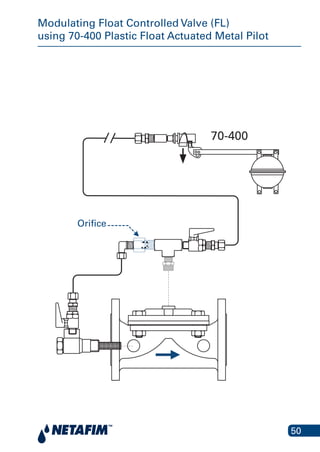

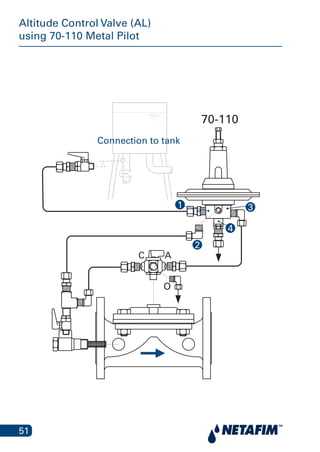

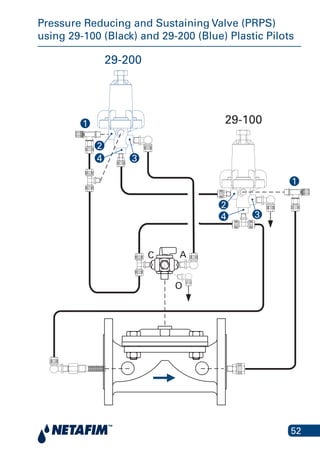

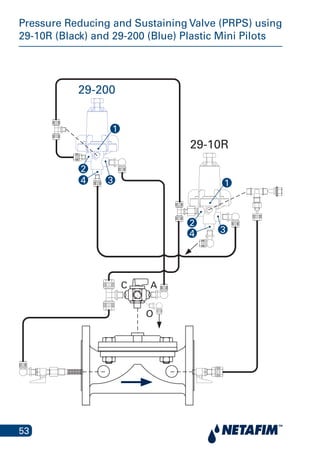

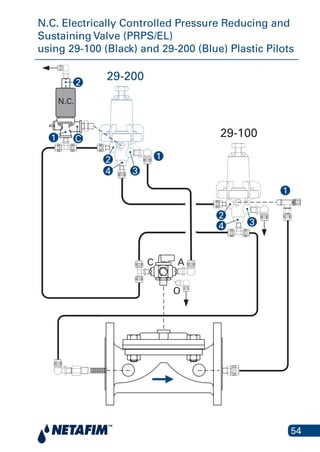

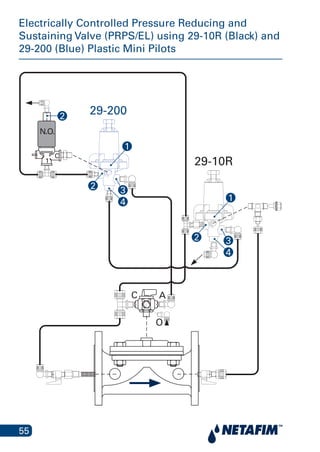

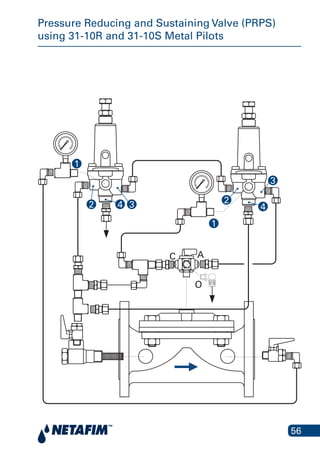

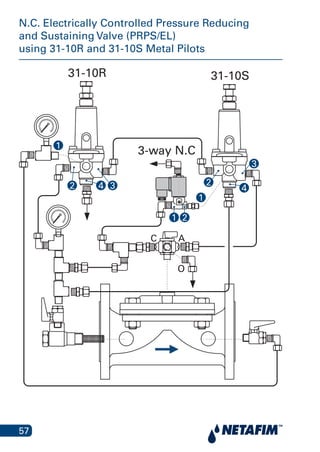

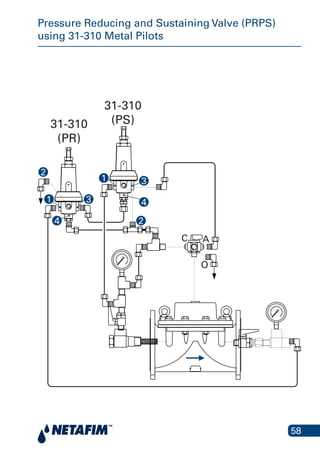

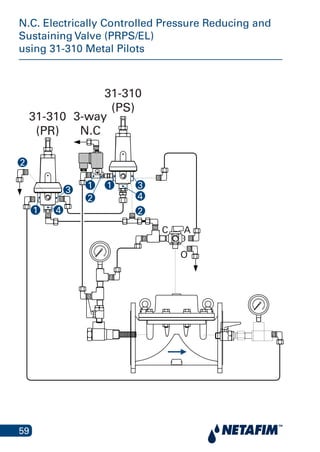

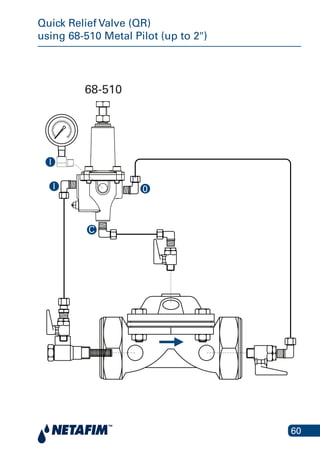

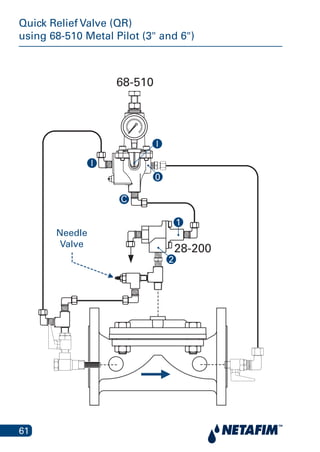

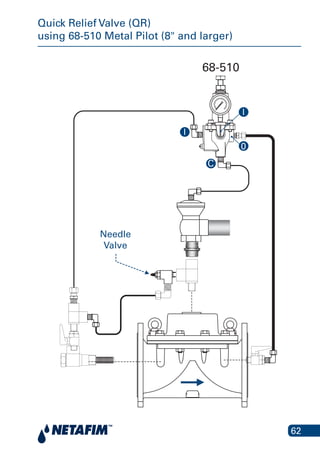

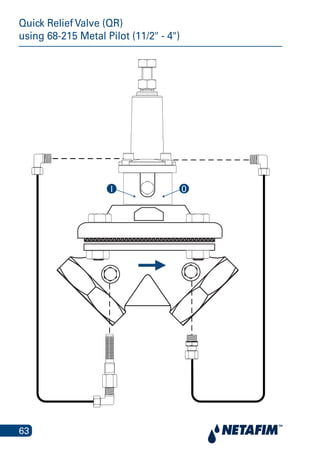

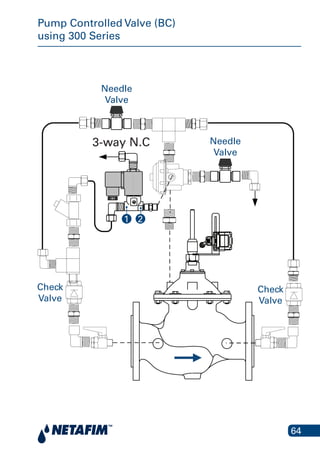

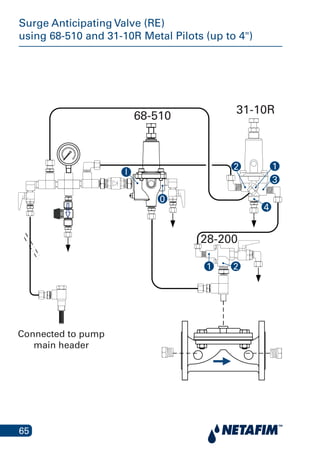

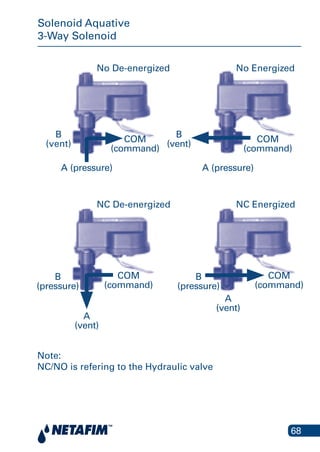

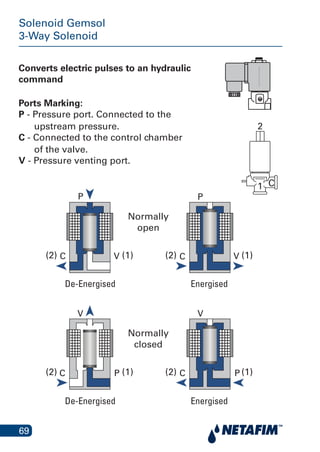

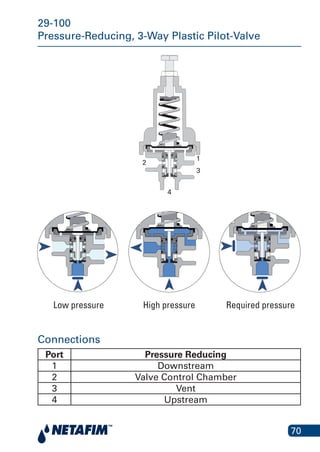

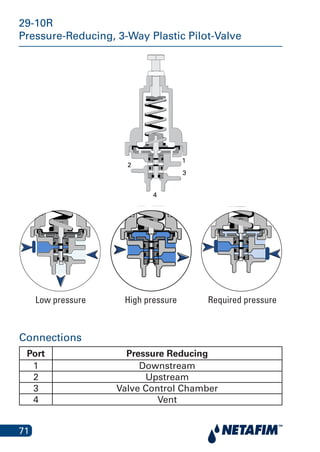

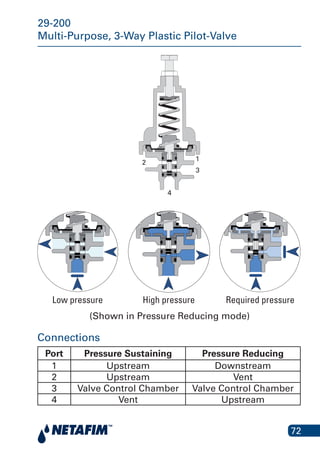

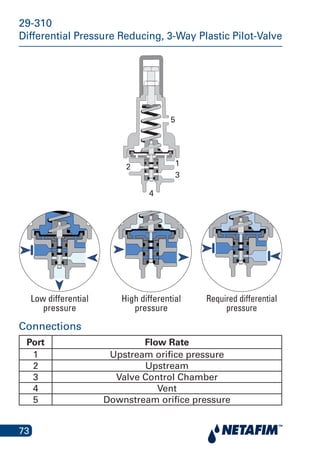

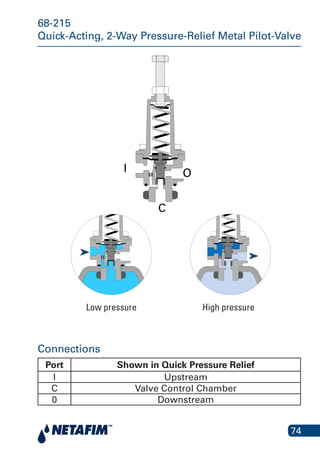

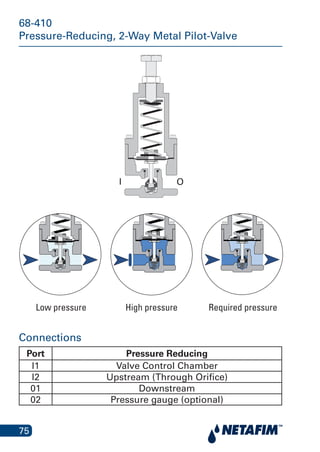

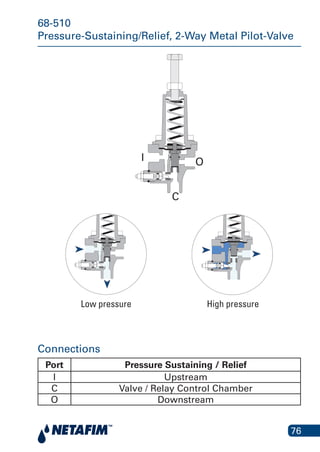

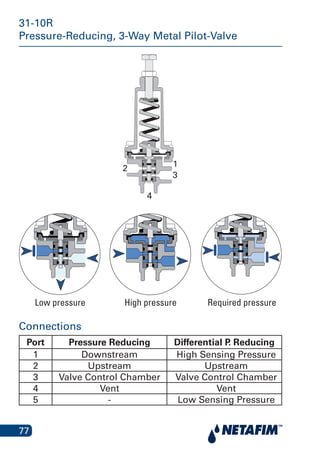

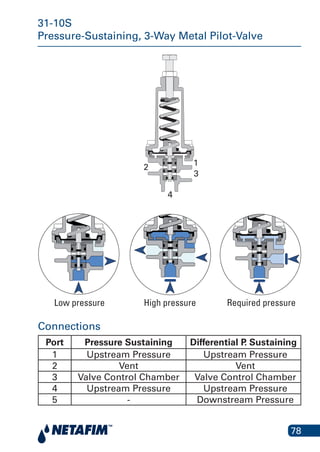

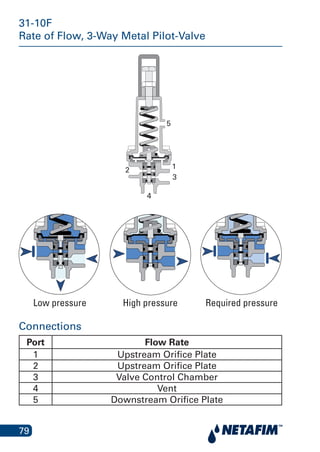

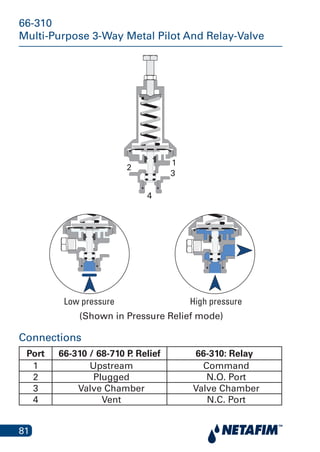

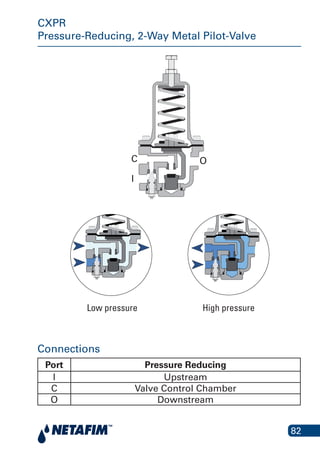

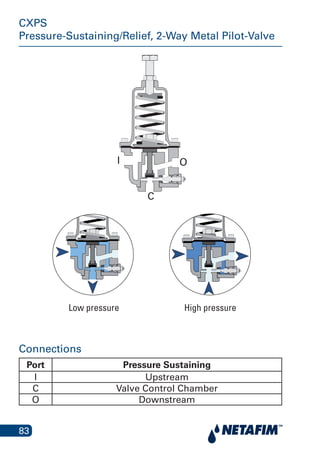

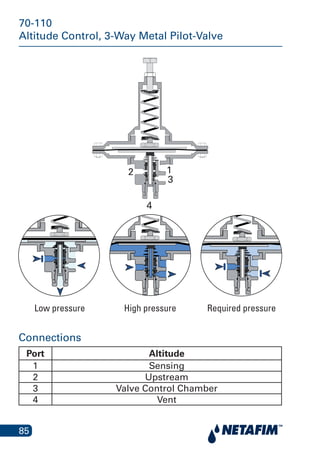

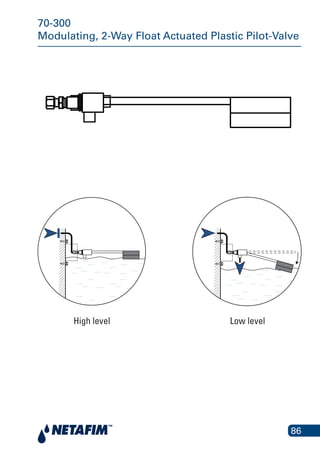

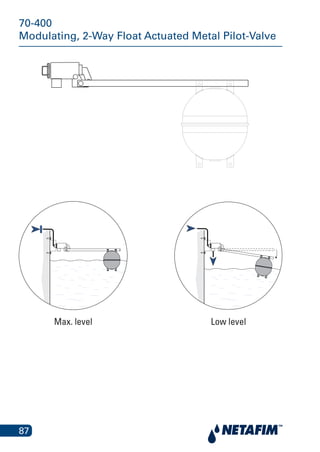

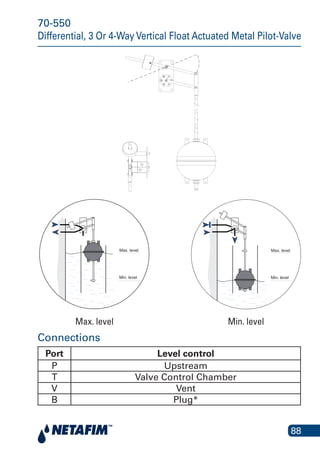

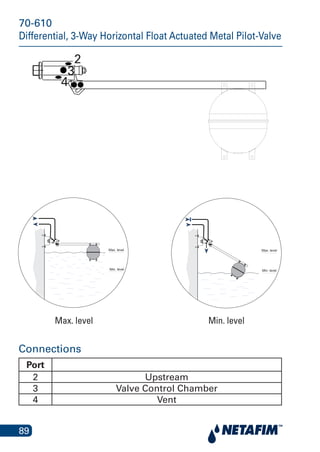

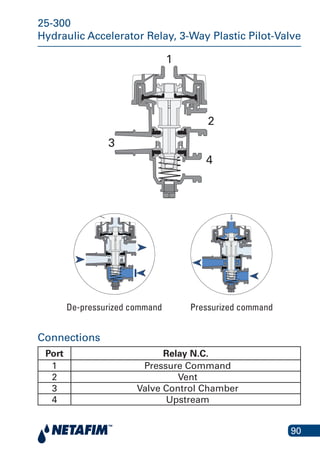

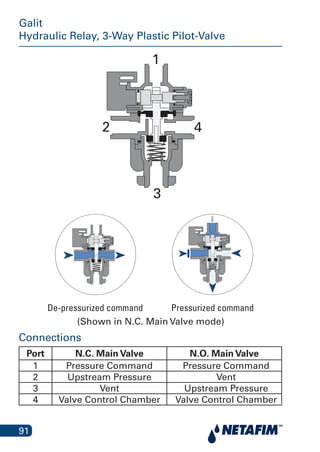

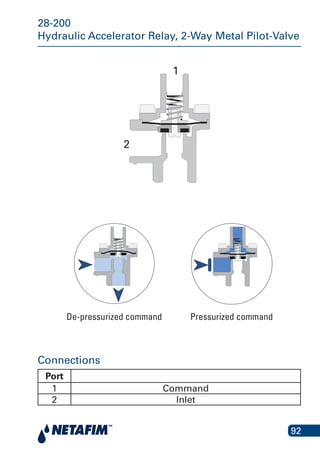

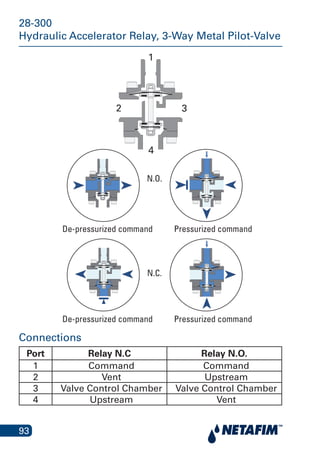

The document contains a list of various types of valves and their components. It includes pressure reducing valves, pressure sustaining valves, electrically controlled valves, remotely controlled valves, and others. Each entry lists the type of valve, the pilot or solenoid used to control it, and a diagram of how it functions. The document provides specifications for over 60 different valve configurations.