Embed presentation

Download as PDF, PPTX

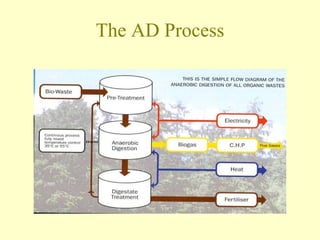

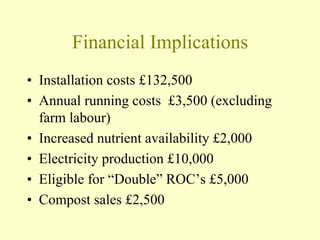

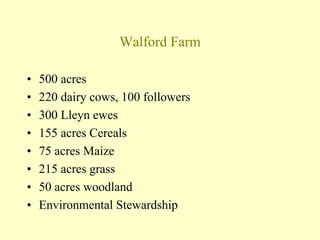

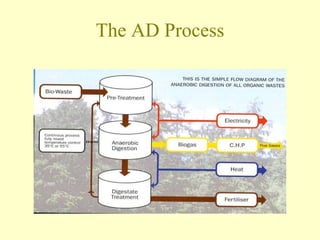

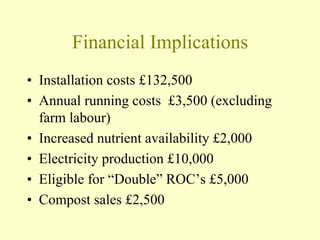

This document discusses a case study of an anaerobic digester installed on Walford Farm in Shropshire, England. It provides details on the farm operations, the installation of the digester in 1994 using funding from Life, and the benefits it provides. The digester processes farm waste through anaerobic digestion to produce biogas which is used in a CHP unit to generate electricity, while the digestate output has enhanced nutrients for use as fertilizer. The financial analysis shows the installation costs were recouped through annual income from electricity production and other benefits.