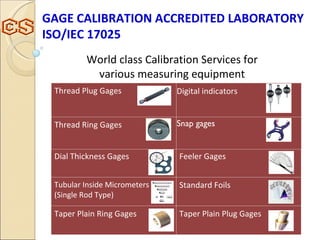

The document outlines the capabilities and certifications of CCS Groups' various divisions, including surface treatments and aerospace bracket manufacturing. It emphasizes NADCAP certifications for multiple processes such as anodizing, passivation, and non-destructive testing. Additionally, it highlights quality equipment and calibration services used in the manufacturing and inspection processes.