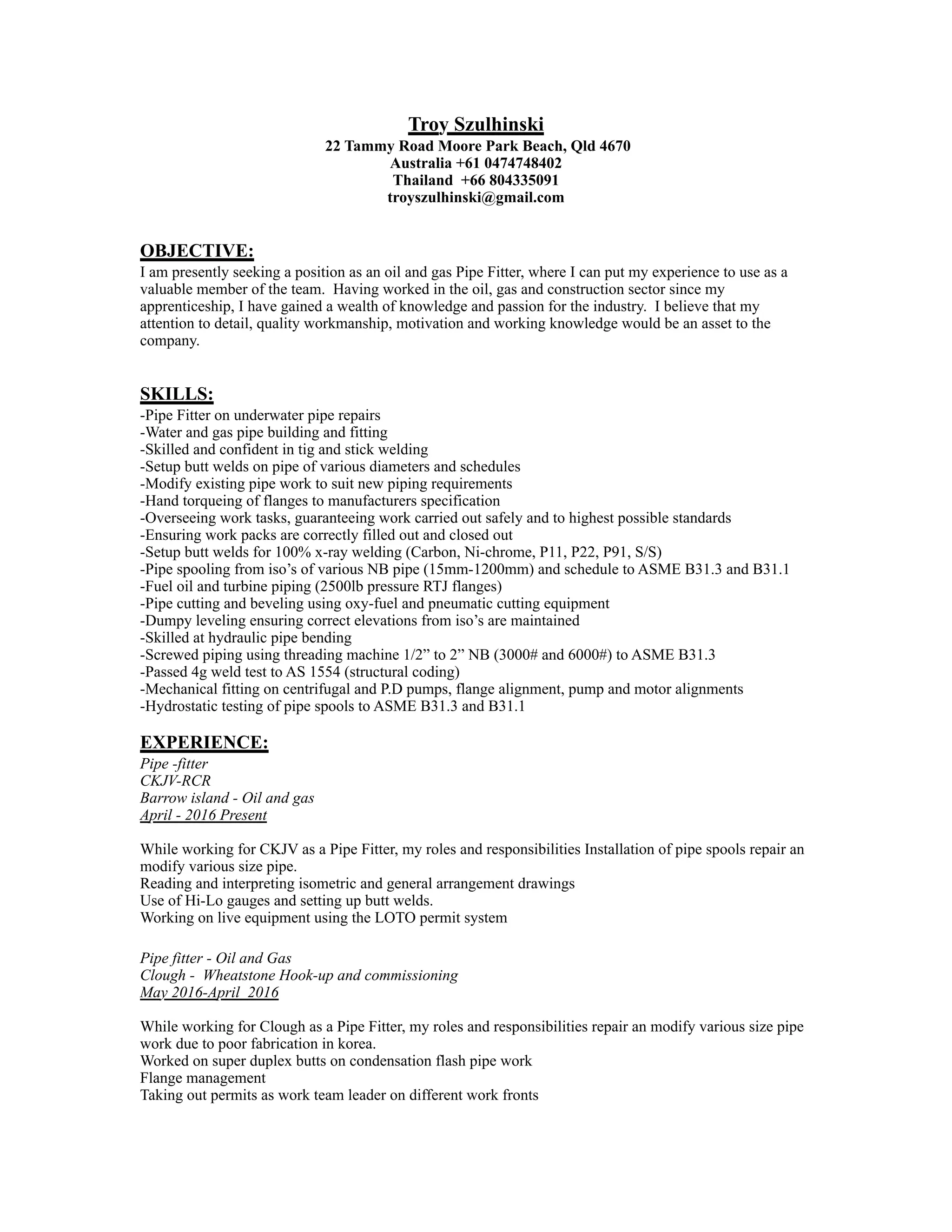

Troy Szulhinski is an experienced pipe fitter with over 10 years of experience in the oil, gas, and construction industries. He has worked on various projects involving pipe installation, repair, and modification. His skills include TIG and stick welding, pipe spooling, cutting, bending, flange installation, and ensuring work is done safely and to high standards. He is seeking a new position as a pipe fitter where he can continue contributing as a valuable team member.