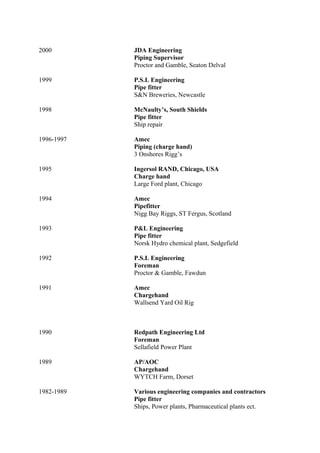

Stephen Brooks is a piping specialist with over 15 years of experience managing pipeline projects across various industries. He has worked internationally on projects in the UK, USA, Norway, Netherlands, and Philippines. His most recent role as the Piping Supervisor at AHL involved installing piping systems at a Procter & Gamble pharmaceutical plant. Brooks has experience working with pipe sizes from 1/2" to 72" in materials like stainless steel, carbon steel, and chrome alloy. He is capable of planning projects, supervising teams, and ensuring work is completed on schedule and to quality standards.