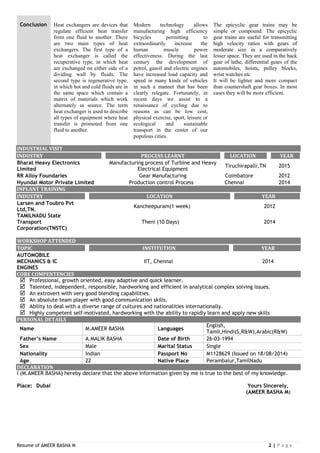

The document is a resume for Ameer Basha M summarizing his education and experience. It includes the following key points:

- Ameer received a postgraduate diploma in process piping design in 2016 and a bachelor's degree in mechanical engineering in 2015.

- His areas of interest and experience include design engineering, product development, quality control, and piping engineering.

- Projects included designing a heat exchanger for a hydraulic press machine and a human-powered vehicle.

- Technical skills include AutoCAD, CREO, programming languages, and Microsoft Office.

- He has participated in internships and industrial visits related to manufacturing processes.