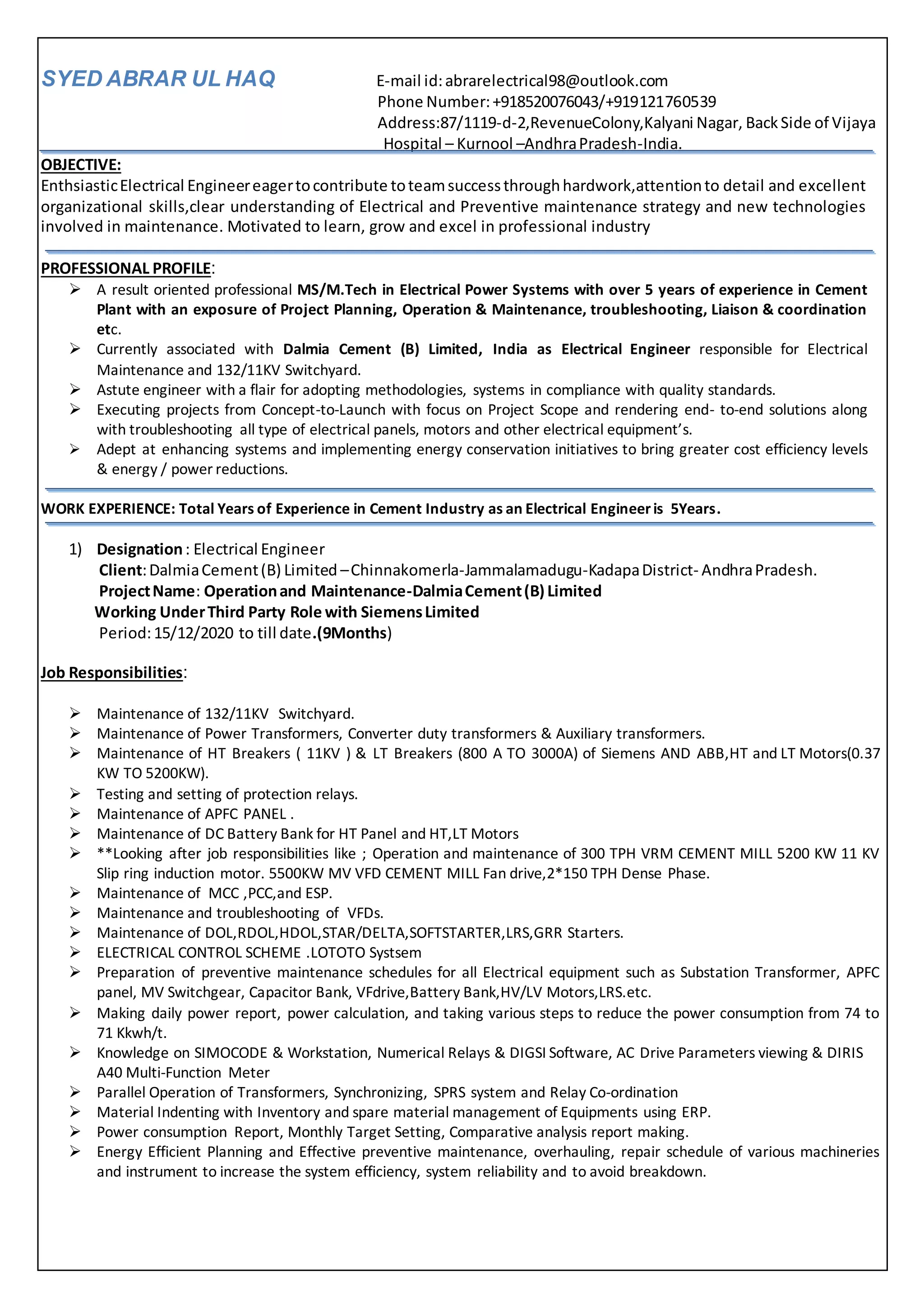

Syed Abra Ul Haq is an electrical engineer with over 5 years of experience in the cement industry. He is currently working as an electrical engineer at Dalmia Cement responsible for electrical maintenance and the 132/11kV switchyard. He holds an M.Tech in Electrical Power Systems and has experience maintaining electrical equipment including transformers, switchgear, motors, VFDs, and more. He is seeking new opportunities as an electrical engineer or related role where he can utilize his skills in electrical planning, maintenance, and project management.