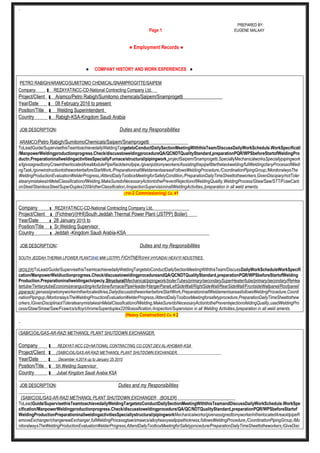

This curriculum vitae is for Mr. Eugenio Conahap Malaay, who is seeking a position as a welding supervisor or inspector. He has over 10 years of experience in structural welding, piping, and fabrication for oil, gas, mining and other industrial projects in Saudi Arabia, Philippines, Tanzania, Ghana, and UAE. His responsibilities have included supervising welding teams, ensuring quality standards, and managing project schedules and budgets. He is proficient in several welding processes and qualified to international codes and standards.