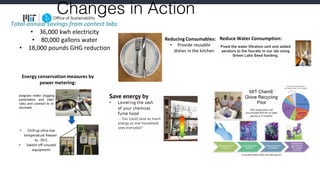

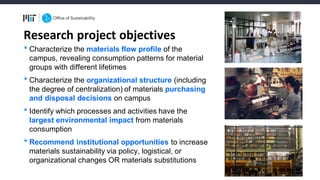

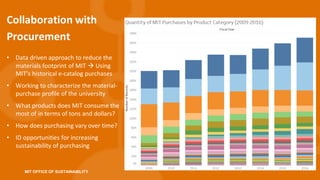

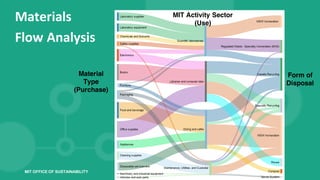

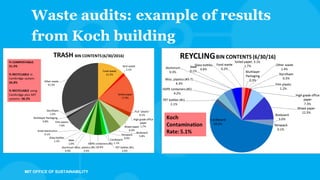

This document summarizes a panel discussion hosted by the MIT Office of Sustainability on constructing the MIT campus as a sustainability test bed. The panelists discussed several projects aimed at decreasing MIT's materials footprint and increasing water and energy efficiency. These included a material flow analysis study characterizing MIT's materials purchases and waste, collaboration with Facilities on waste reduction projects, and a solar test bed project. The discussion also covered a green labs certification program that has engaged labs in sustainability best practices.

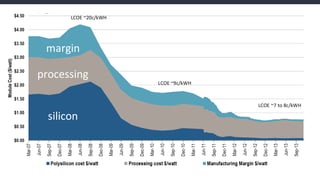

![1990 2000 2010 2020

102

10

3

10

4

10

5

106

cumm.installation[MW]

year

1

10

2014 est 0.45 $/W

2015 est. 0.39 $/W

moduleprice[$/Wp

]

2016 est. 302 GW

2017 proj 368 GW

23% reduction

per doubled

capacity over 35

years

29% growth per

year over 25 years](https://image.slidesharecdn.com/campusasatestbedpanelslides-170602194748/85/Cultivating-the-Test-Bed-Constructing-the-Campus-Lab-14-320.jpg)