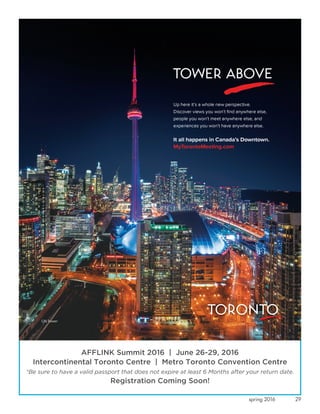

This document is a quarterly publication for members and suppliers of AFFLINK. It includes articles on various topics such as sales and operations, HR updates, supply chain planning, distributor and supplier profiles, emerging executives, preferred service providers, member brands, AFFLINK academy programs, sustainability initiatives, awards and events. The cover story discusses supply chain planning in 2016. Other articles provide advice on finding new clients through introductions and referrals, potential changes to overtime rules, and the value of attending AFFLINK's Summit conference to work on business strategies.