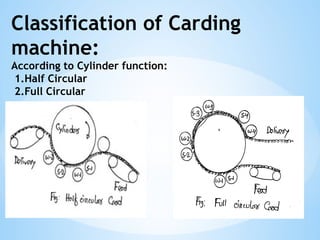

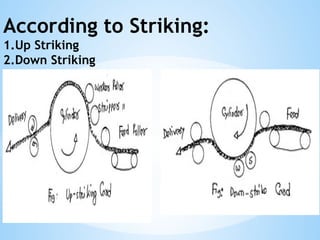

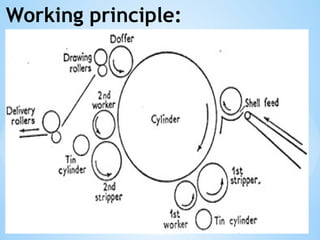

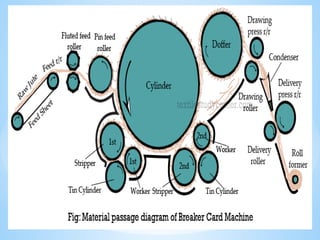

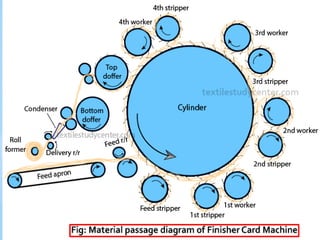

Carding is the process that transforms long jute reeds into a uniform ribbon, achieving objectives such as fiber breakdown, weight uniformity, and dirt removal. Carding machines can be classified by their cylinder functions, striking methods, and processing types, with key components that include rollers and flats. The breaker carding machine, primarily down striking and half-circular, serves to individualize fibers, draft them, and form a sliver.