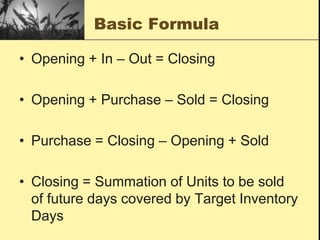

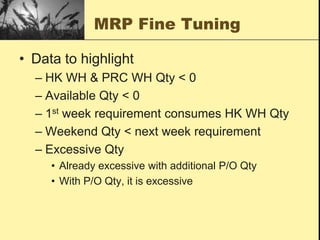

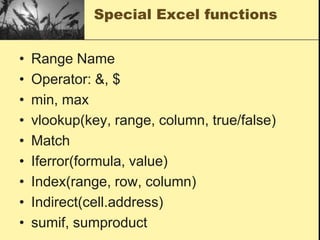

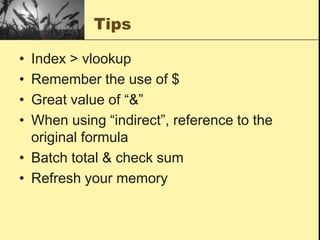

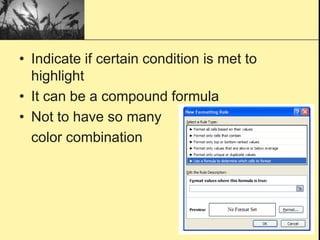

This document outlines a two-day course on costing and inventory management using Excel. Day 1 covers underlying MRP principles, inventory forecasting, bills of materials, and Excel modeling. Day 2 focuses on template construction, stock aging reports, and Excel skills like functions and formulas. Key concepts discussed include target inventory levels, safety stock, materials requirements planning, bills of materials, routings, and using Excel functions to analyze inventory data.