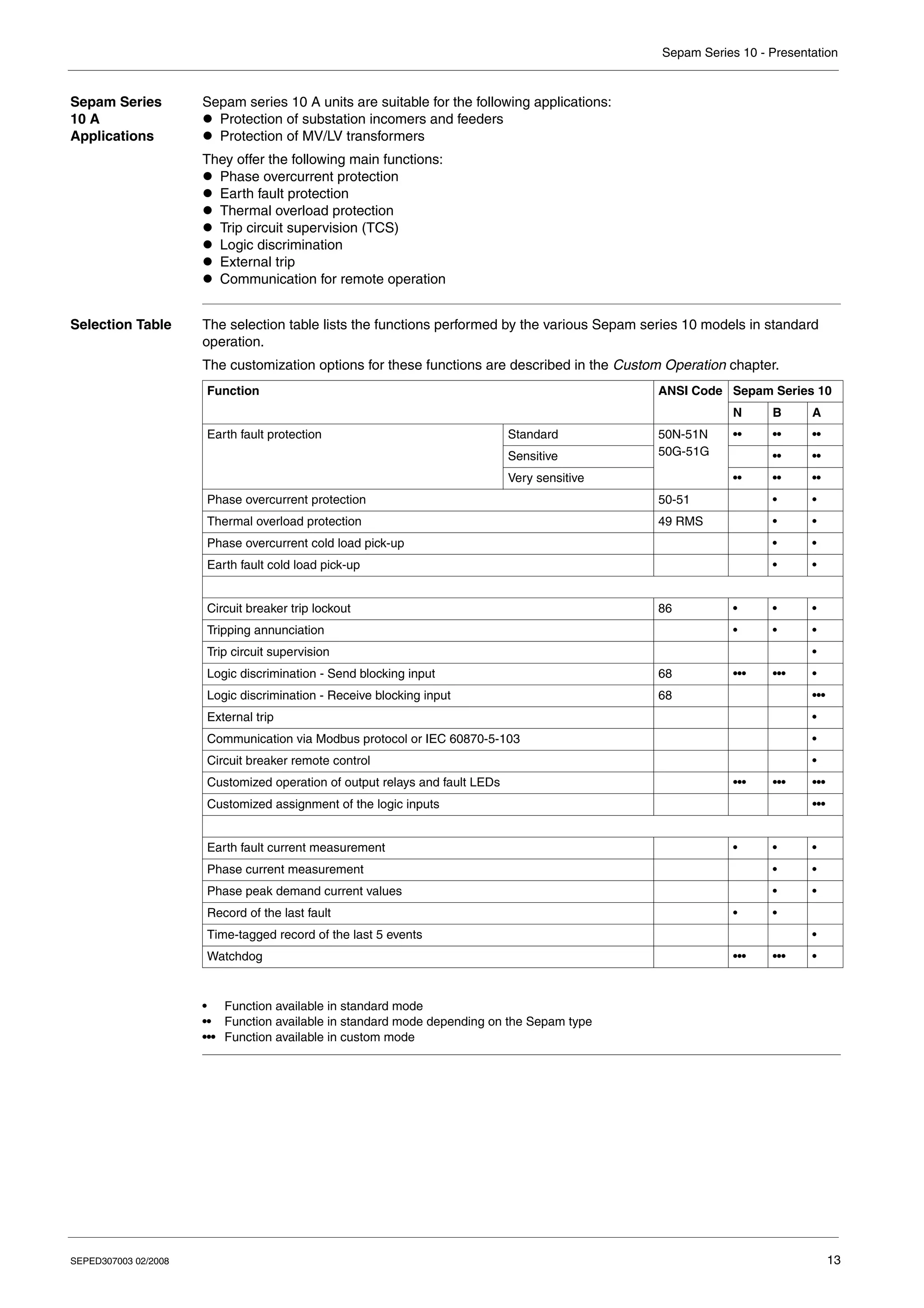

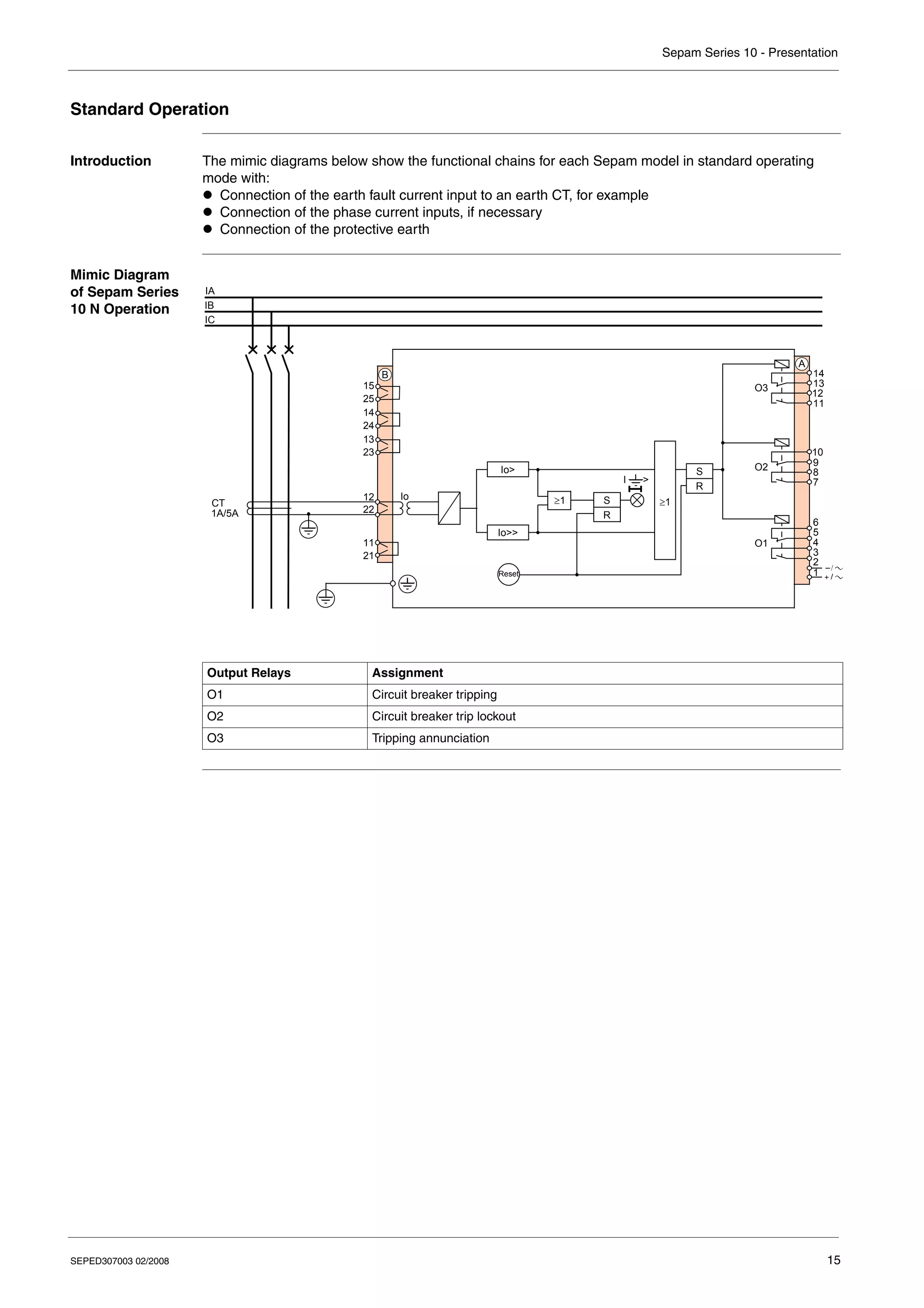

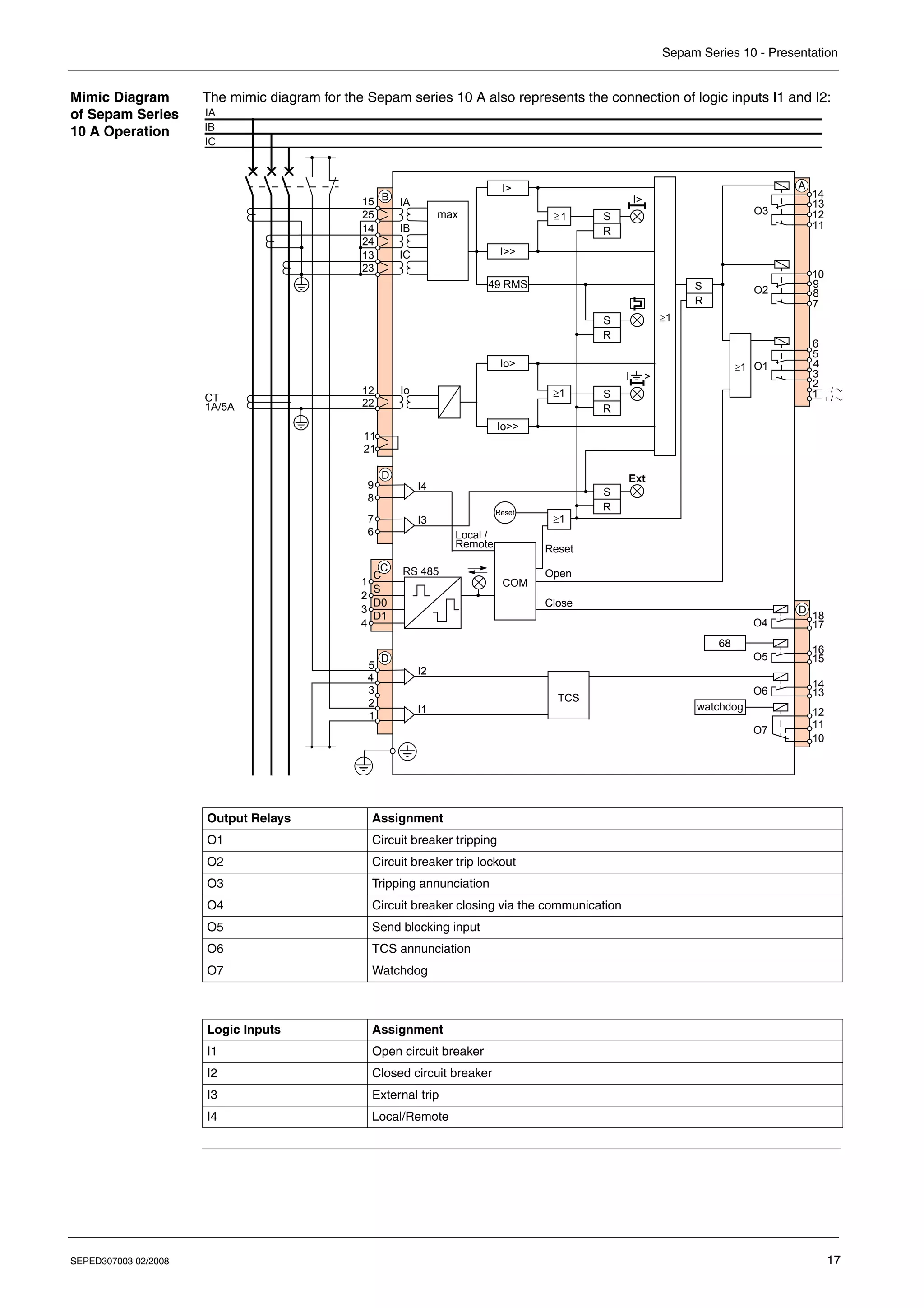

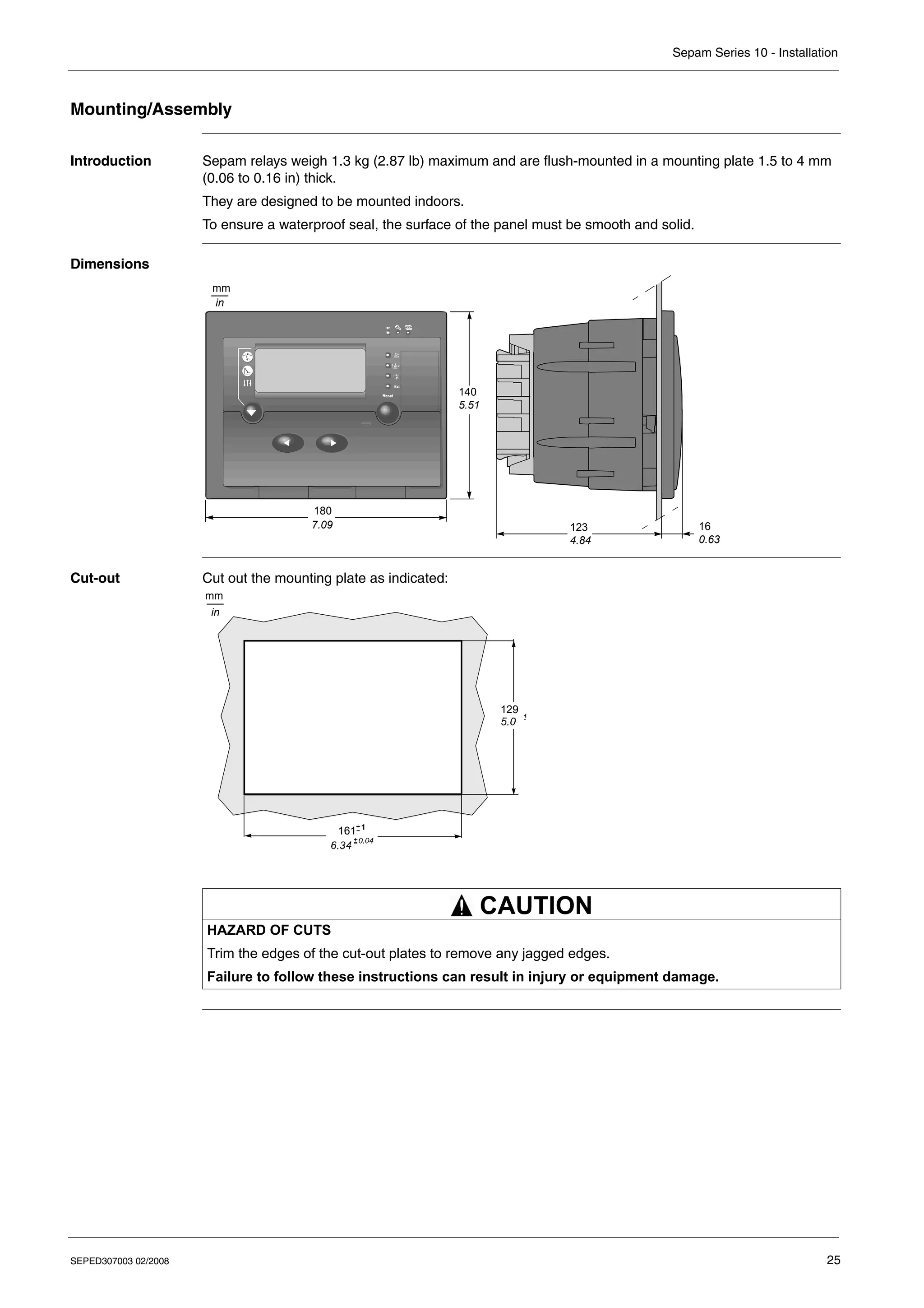

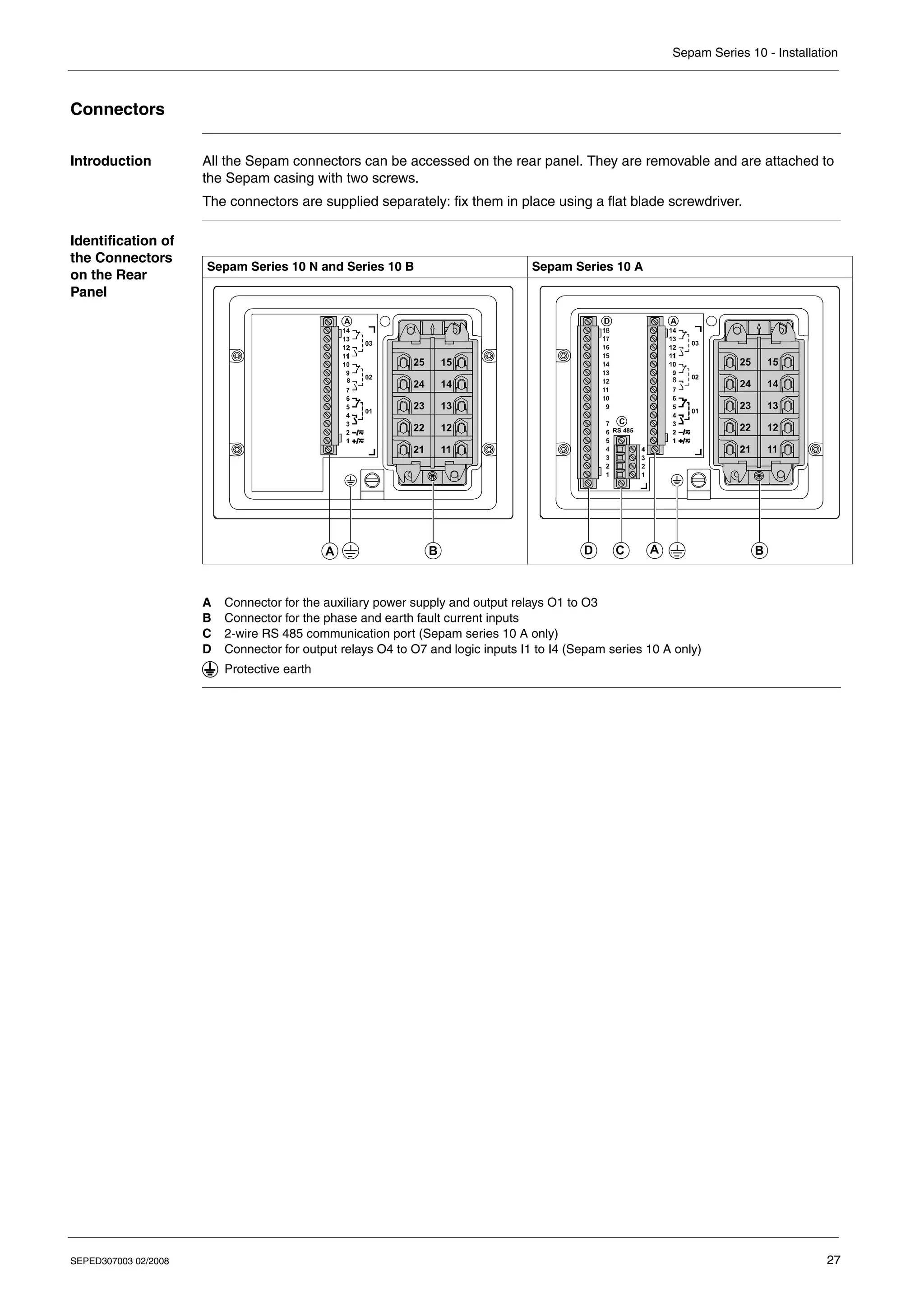

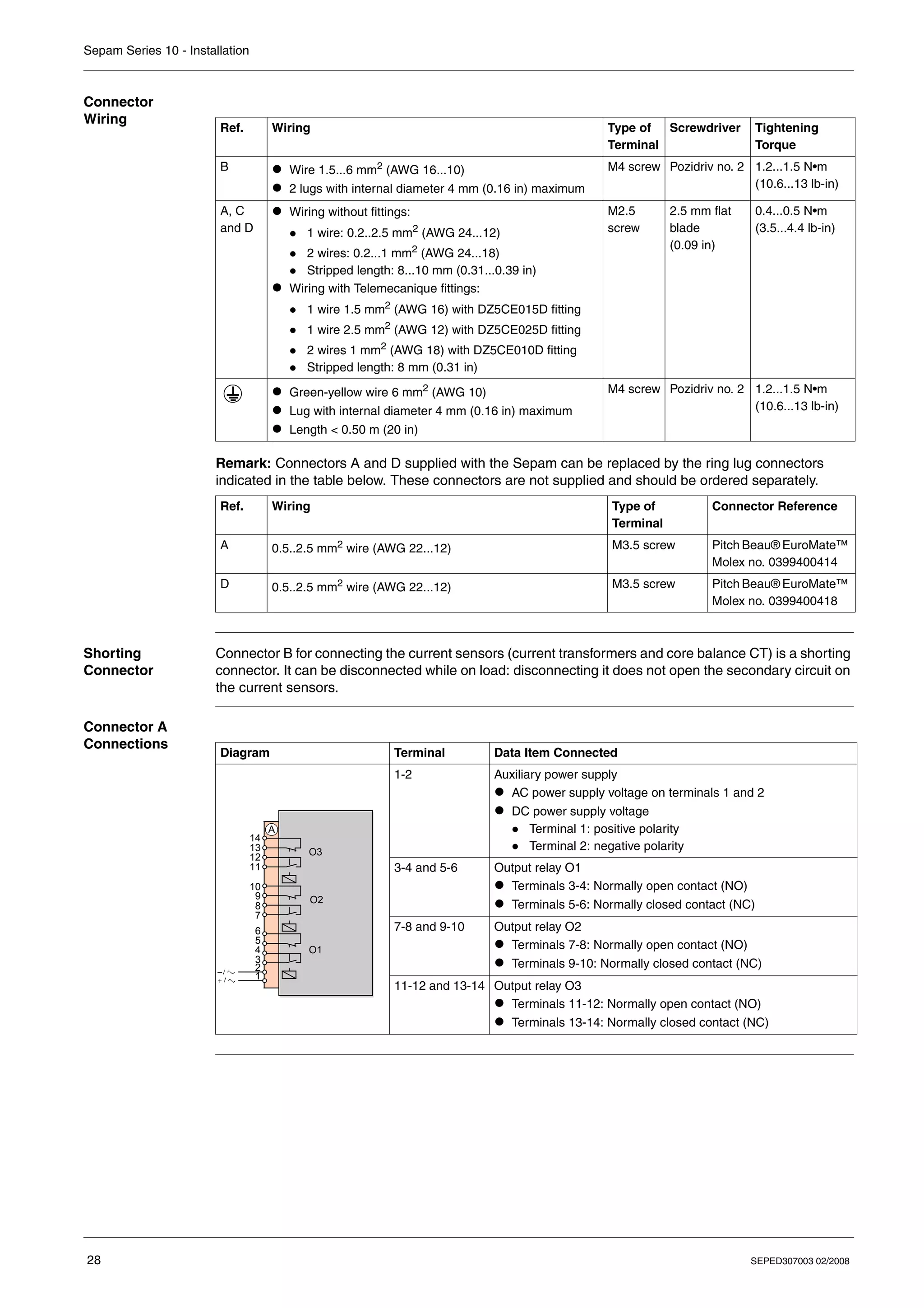

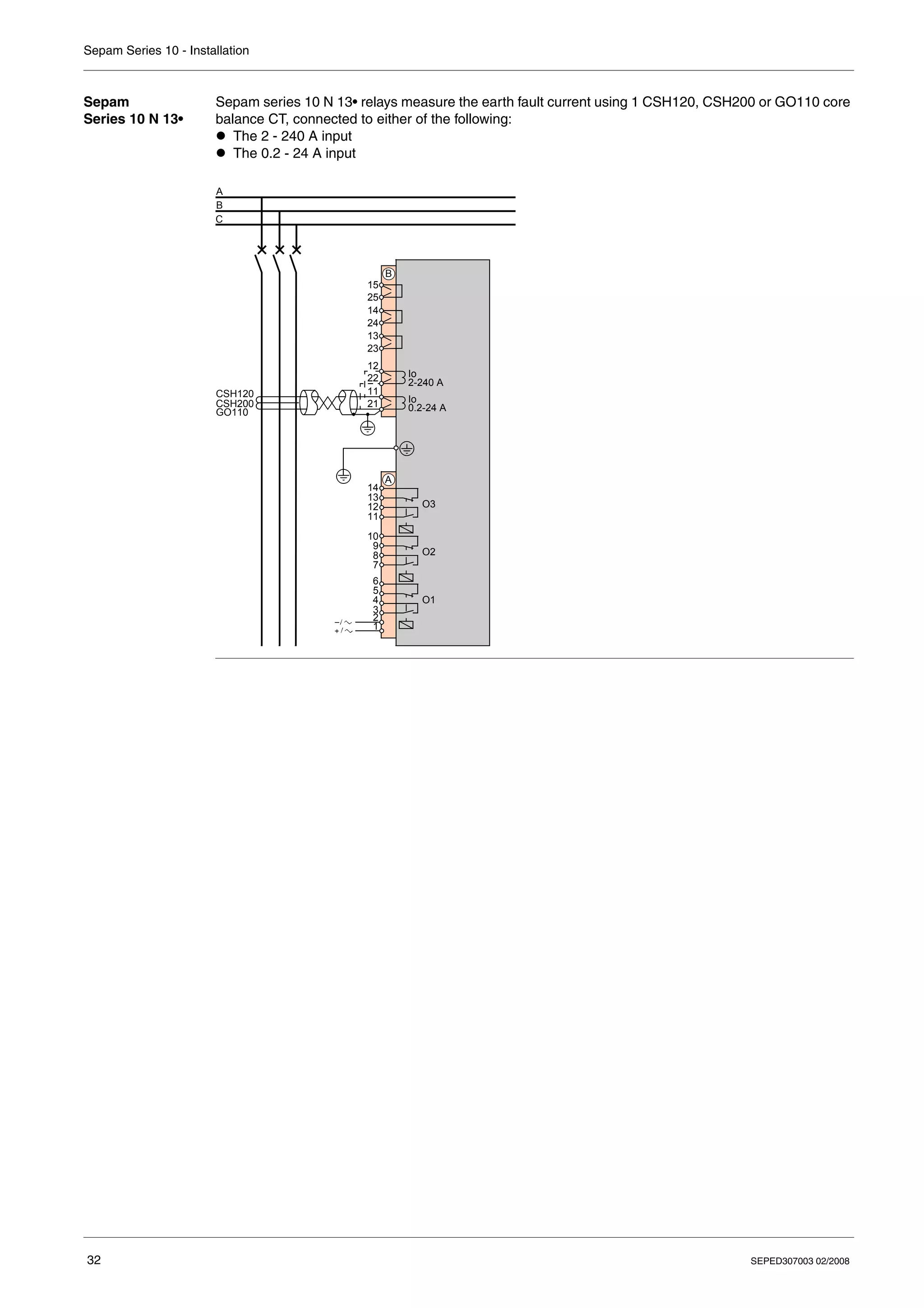

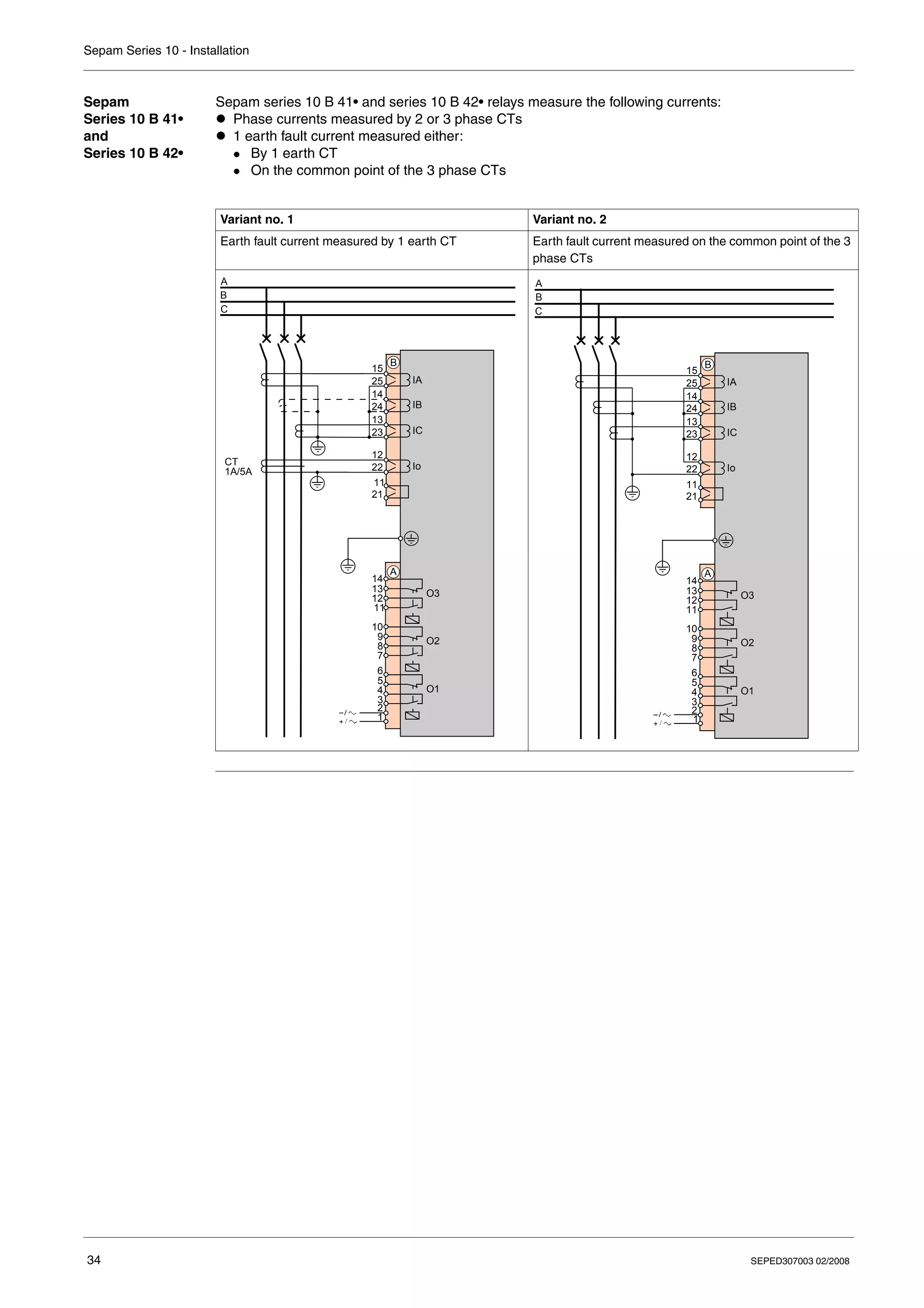

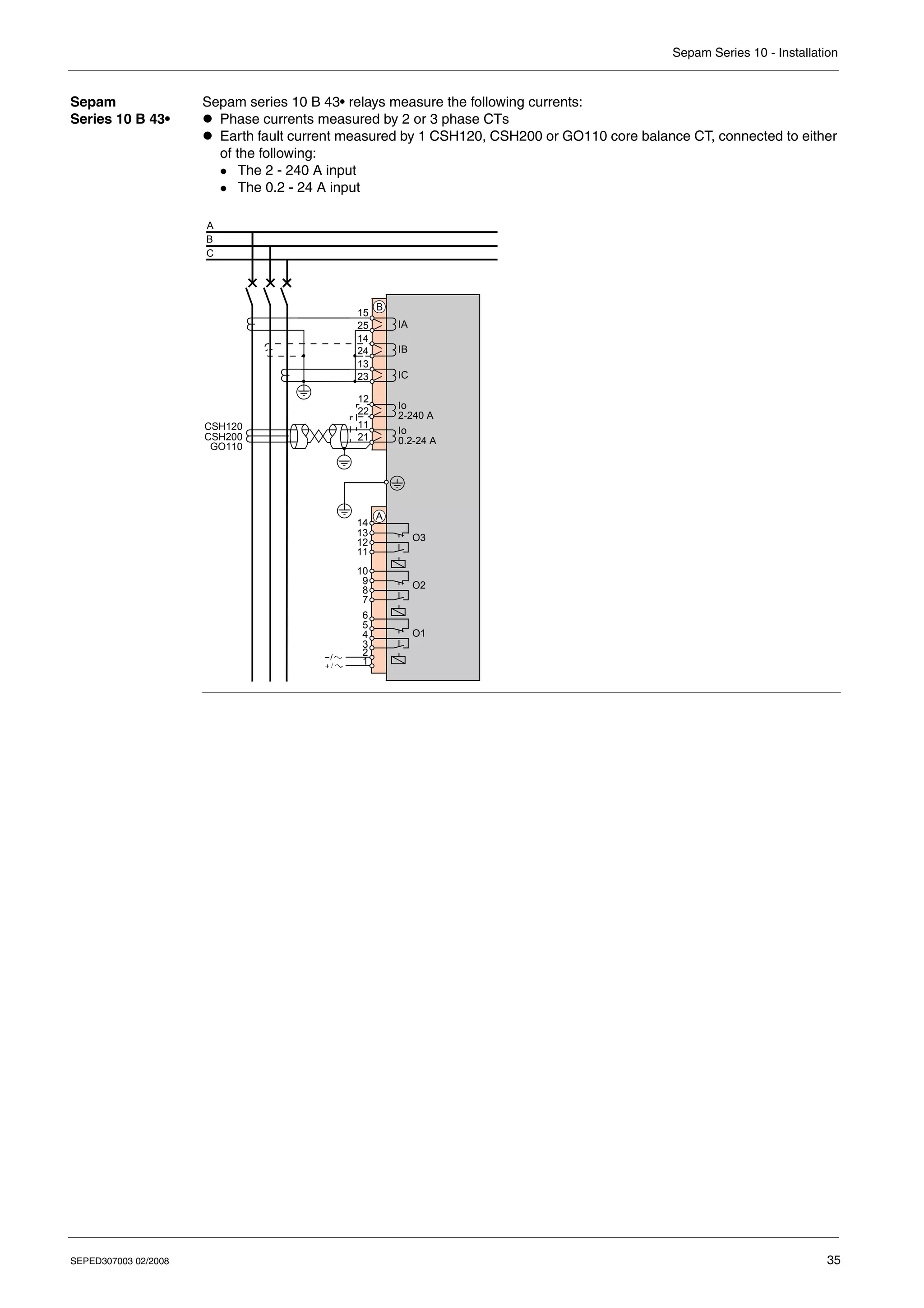

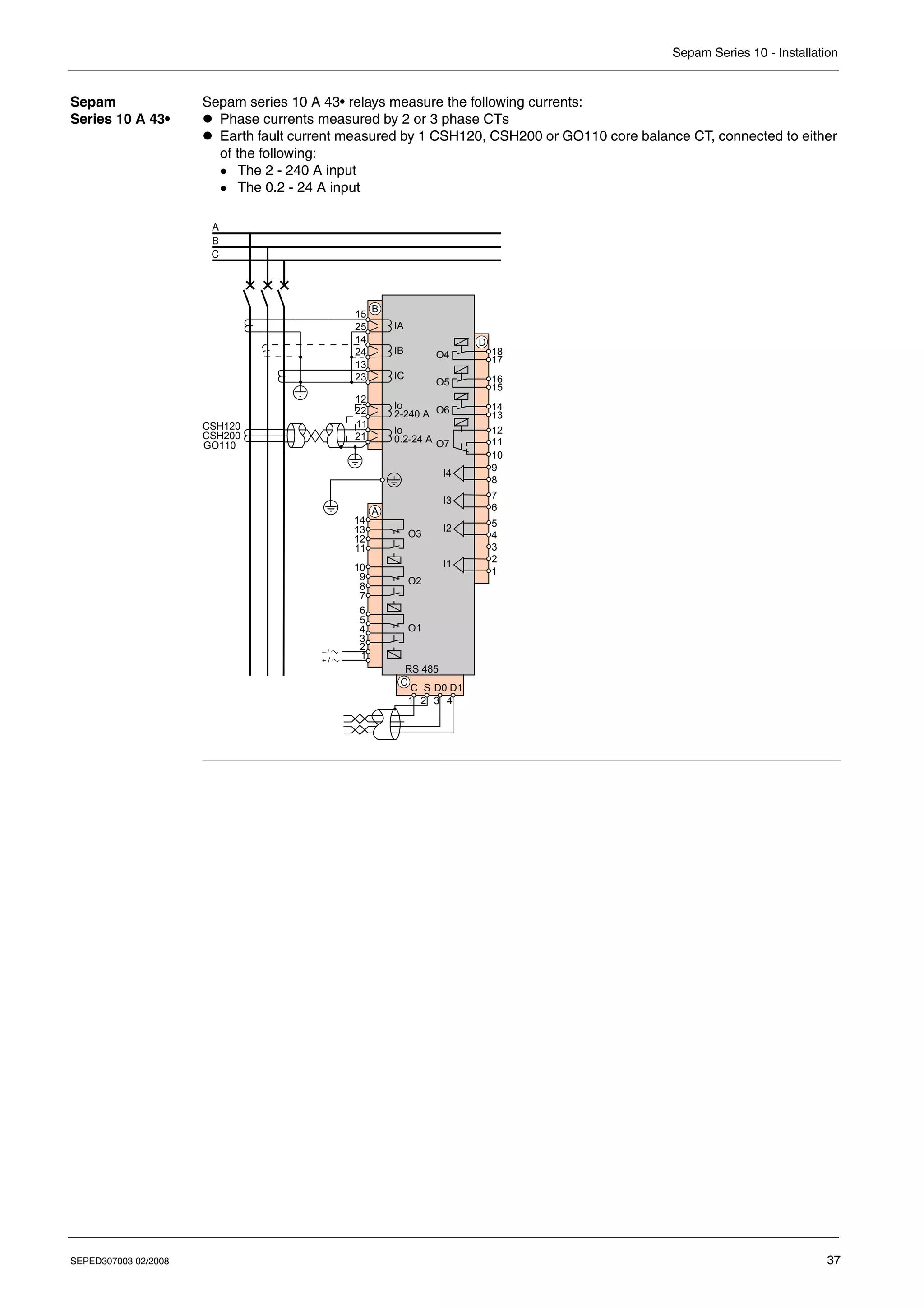

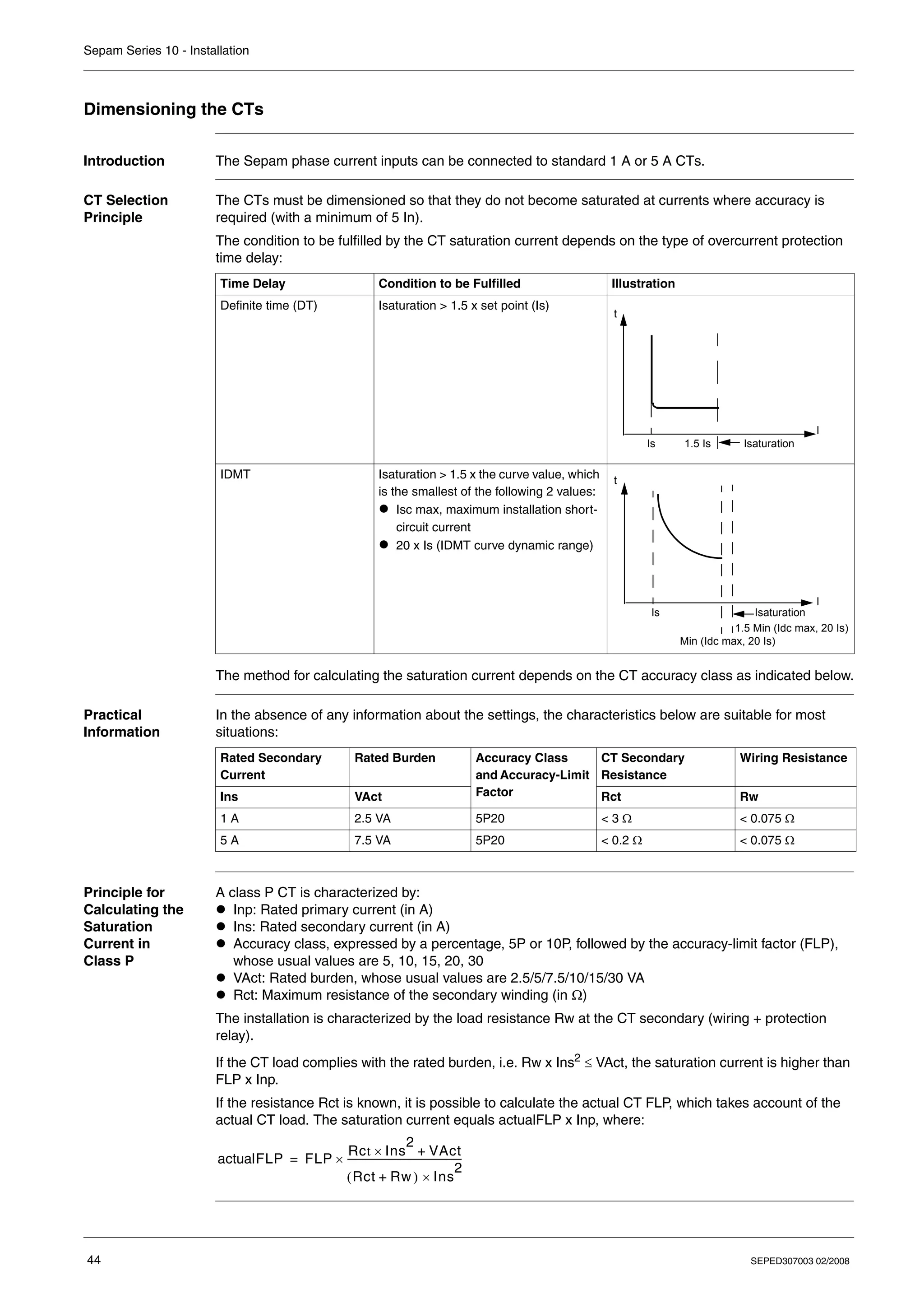

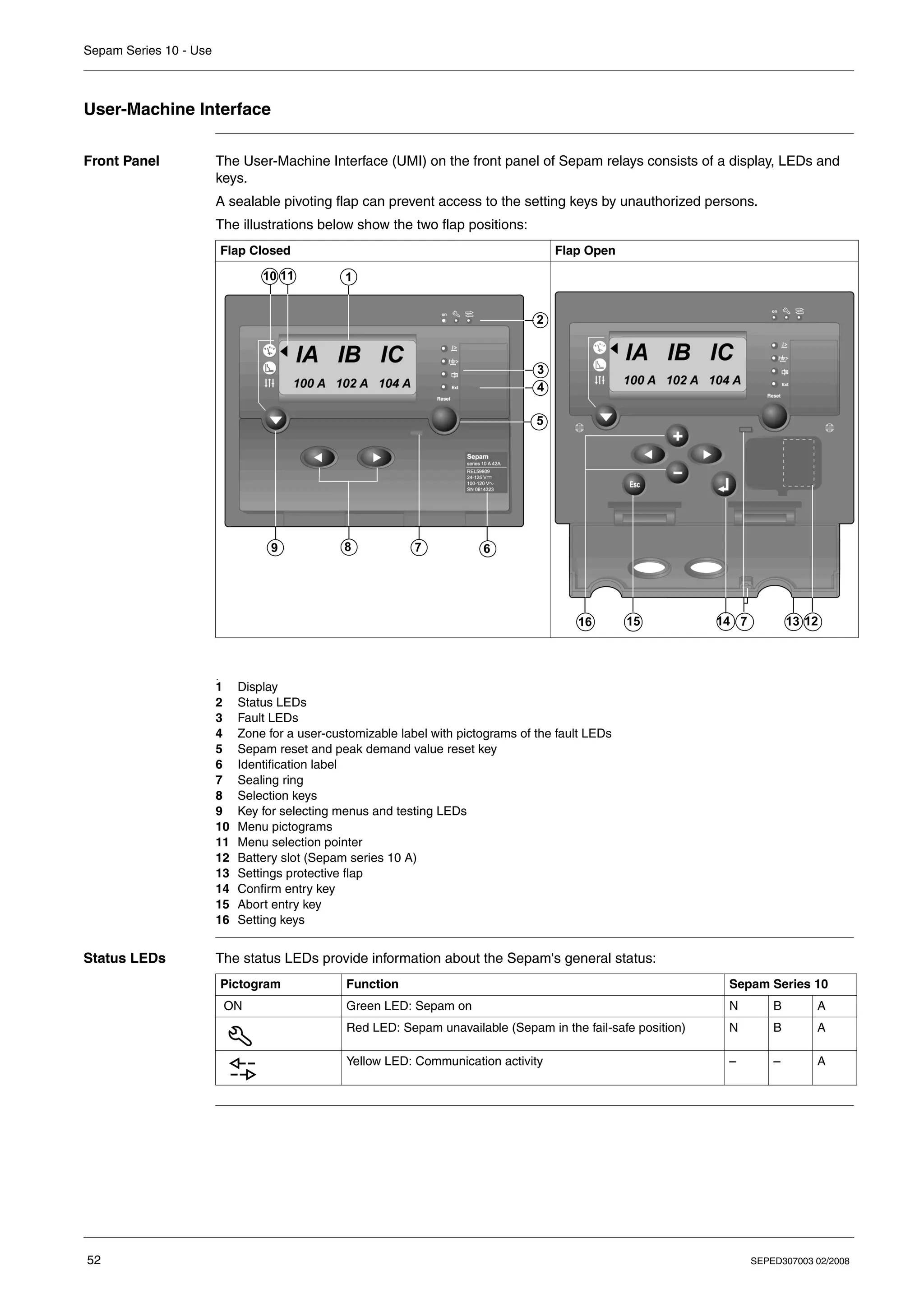

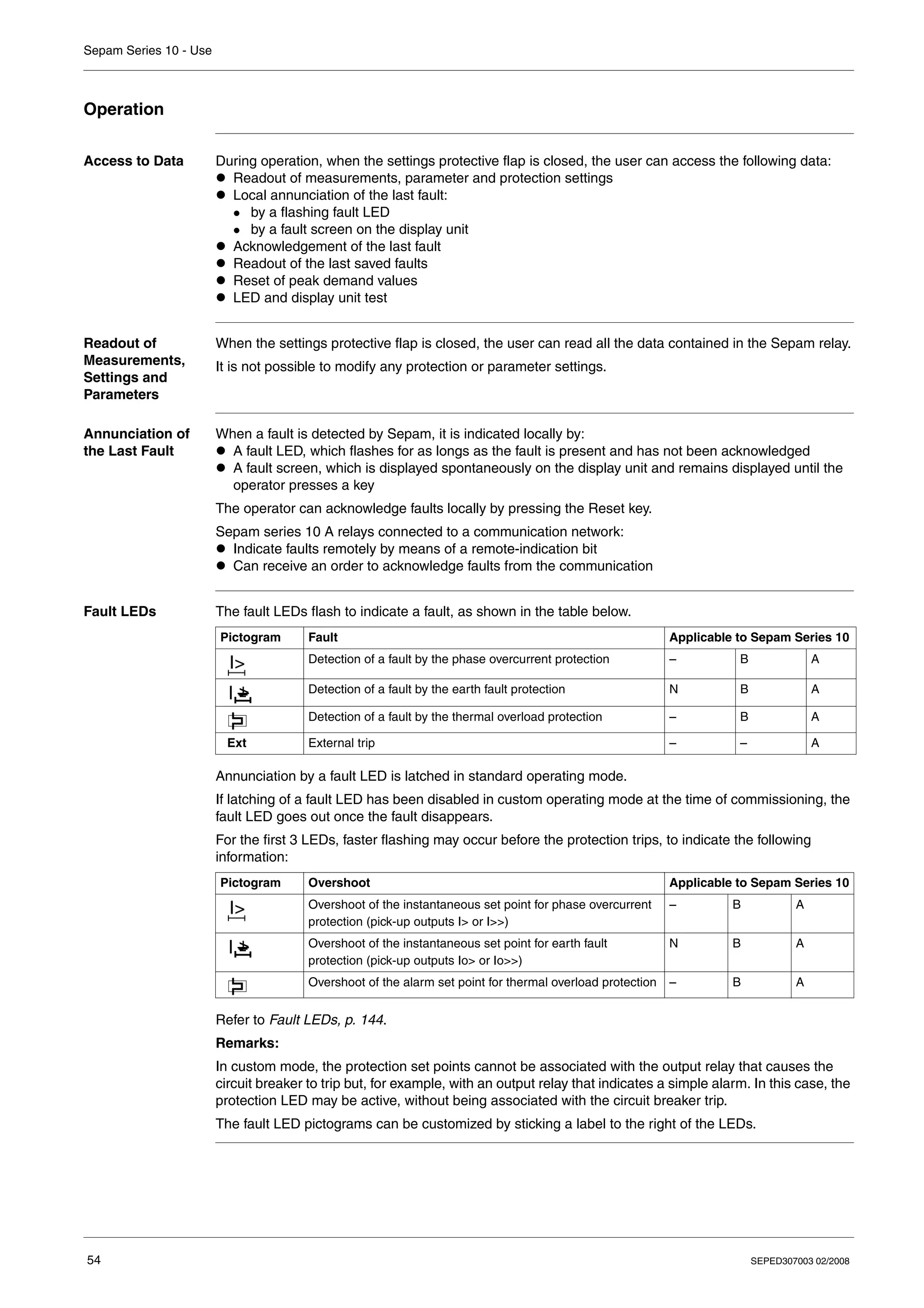

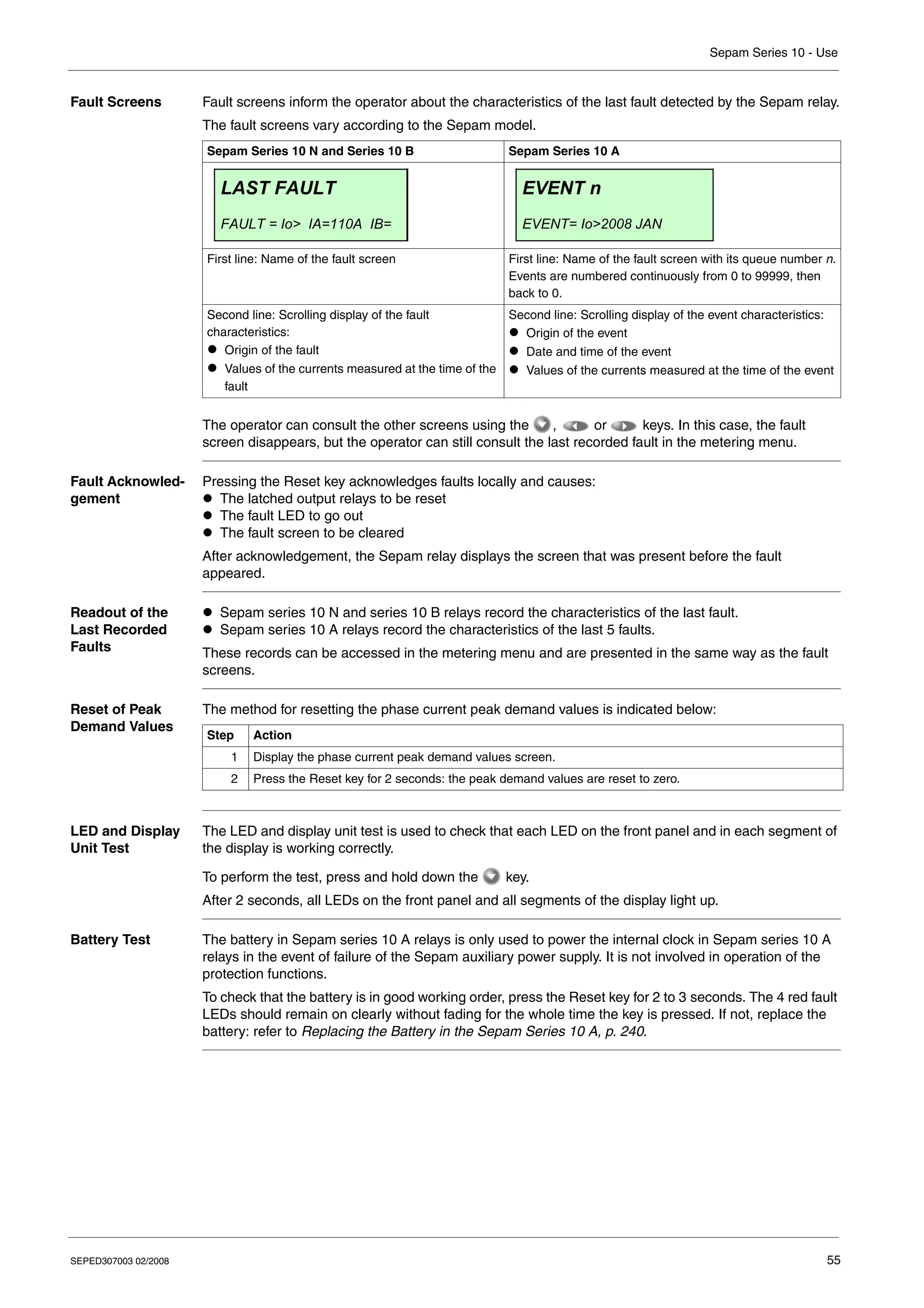

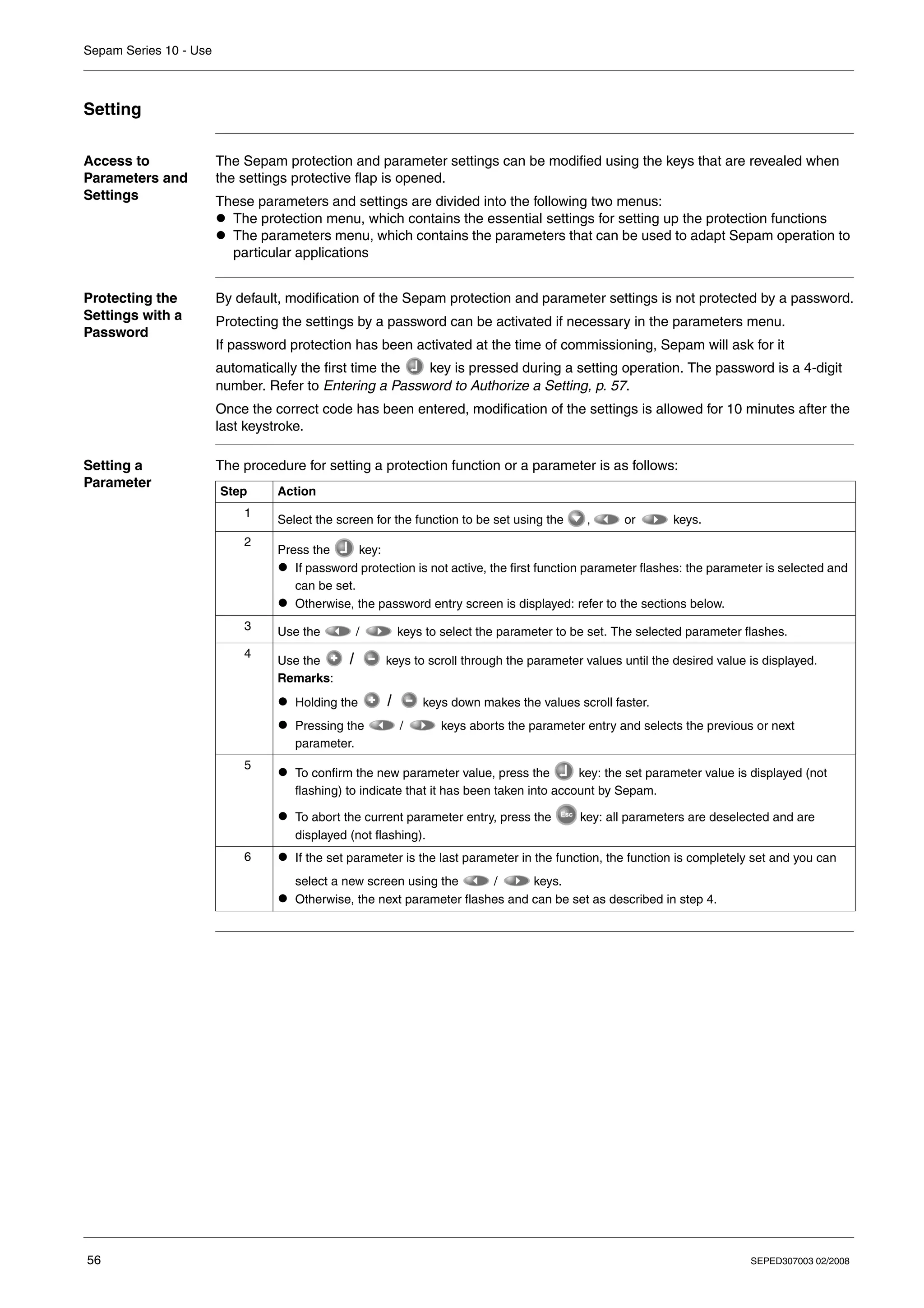

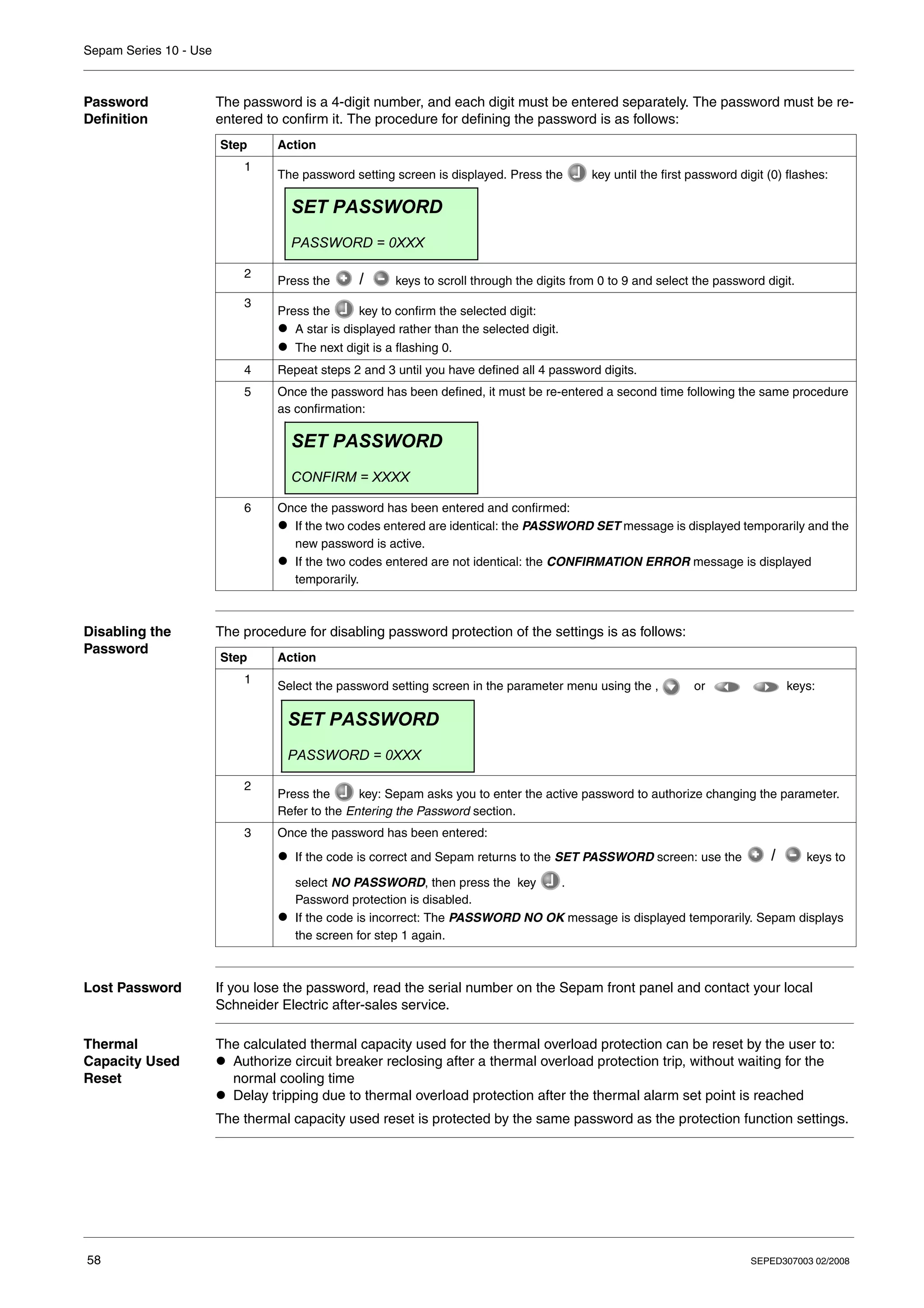

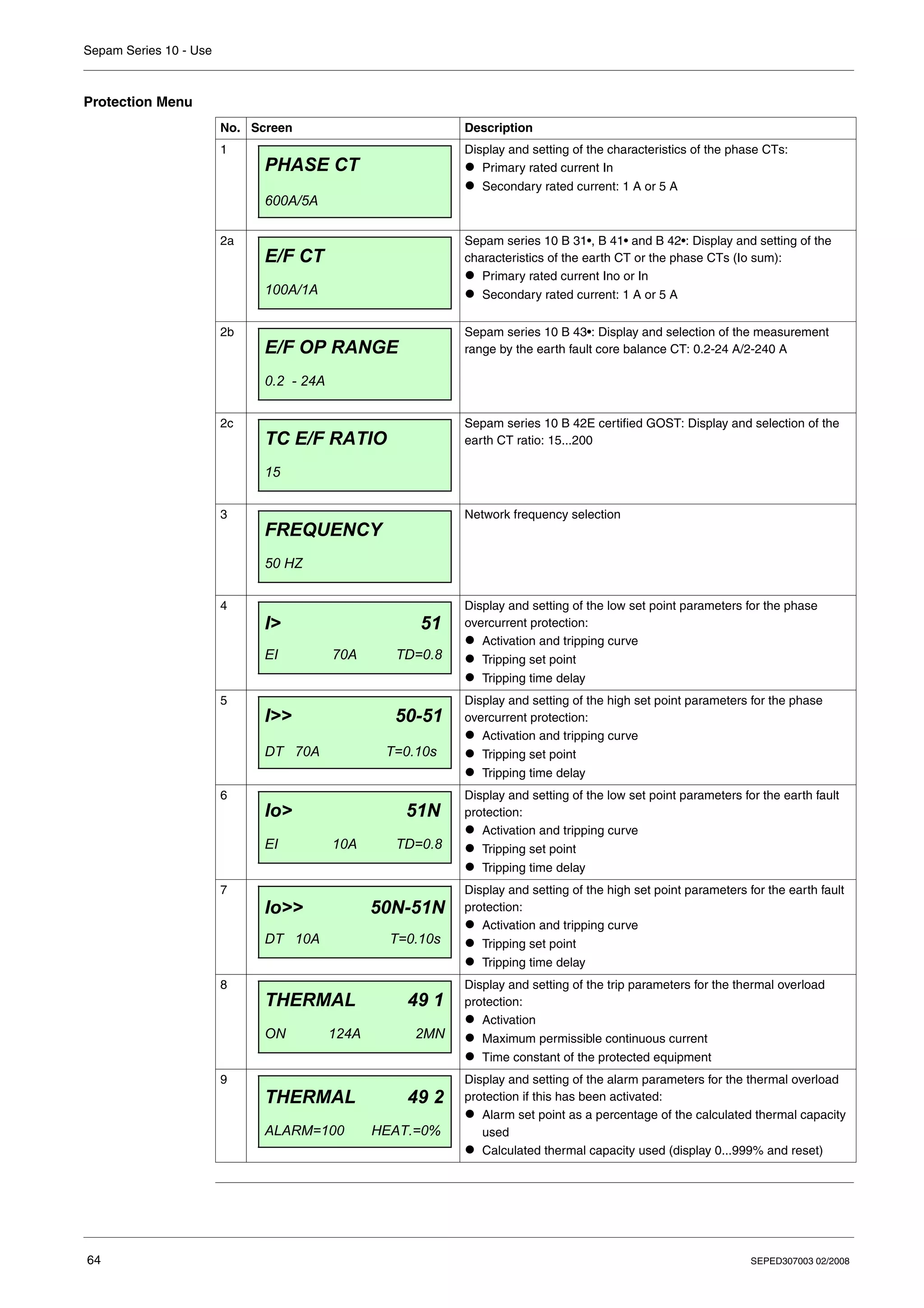

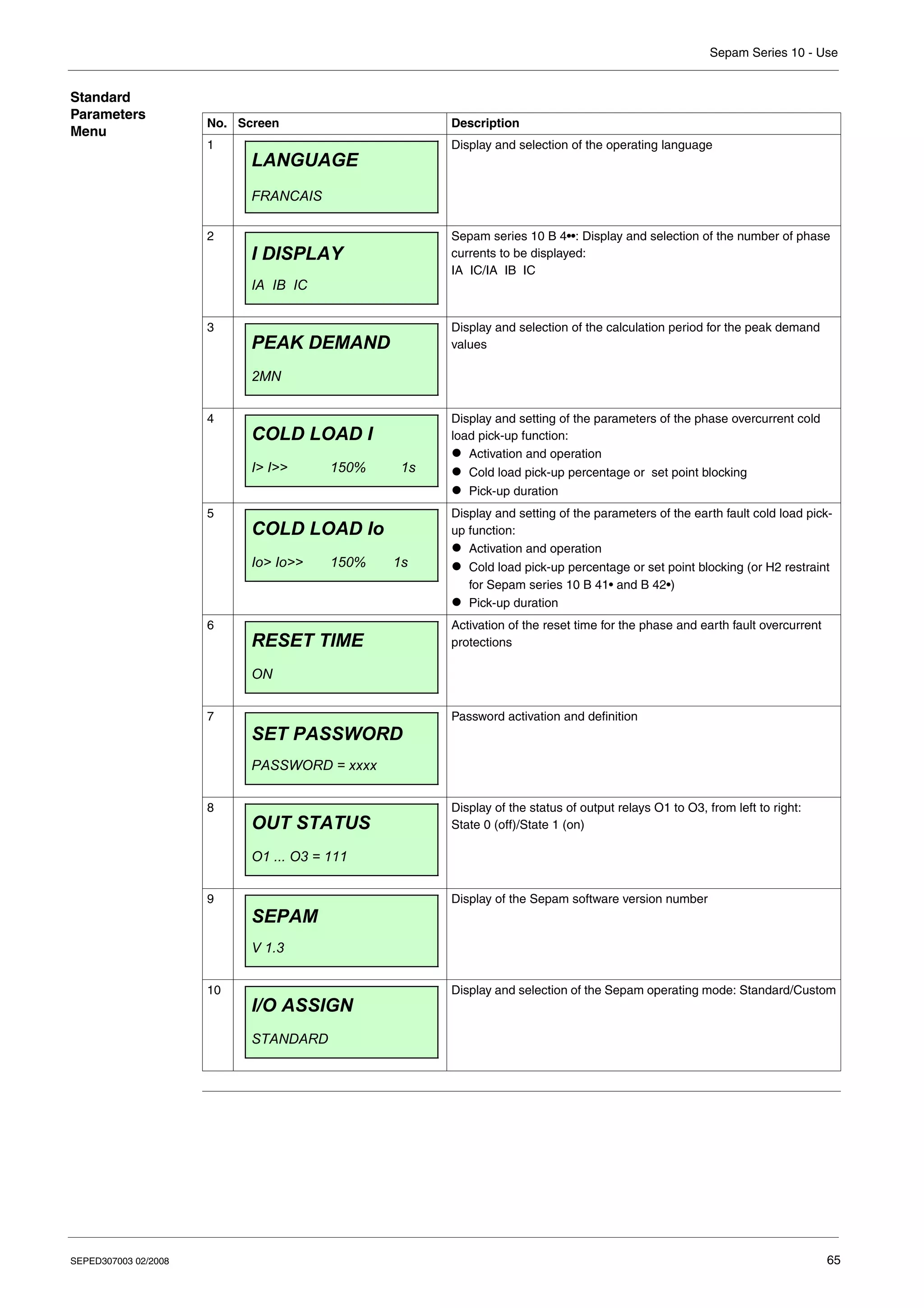

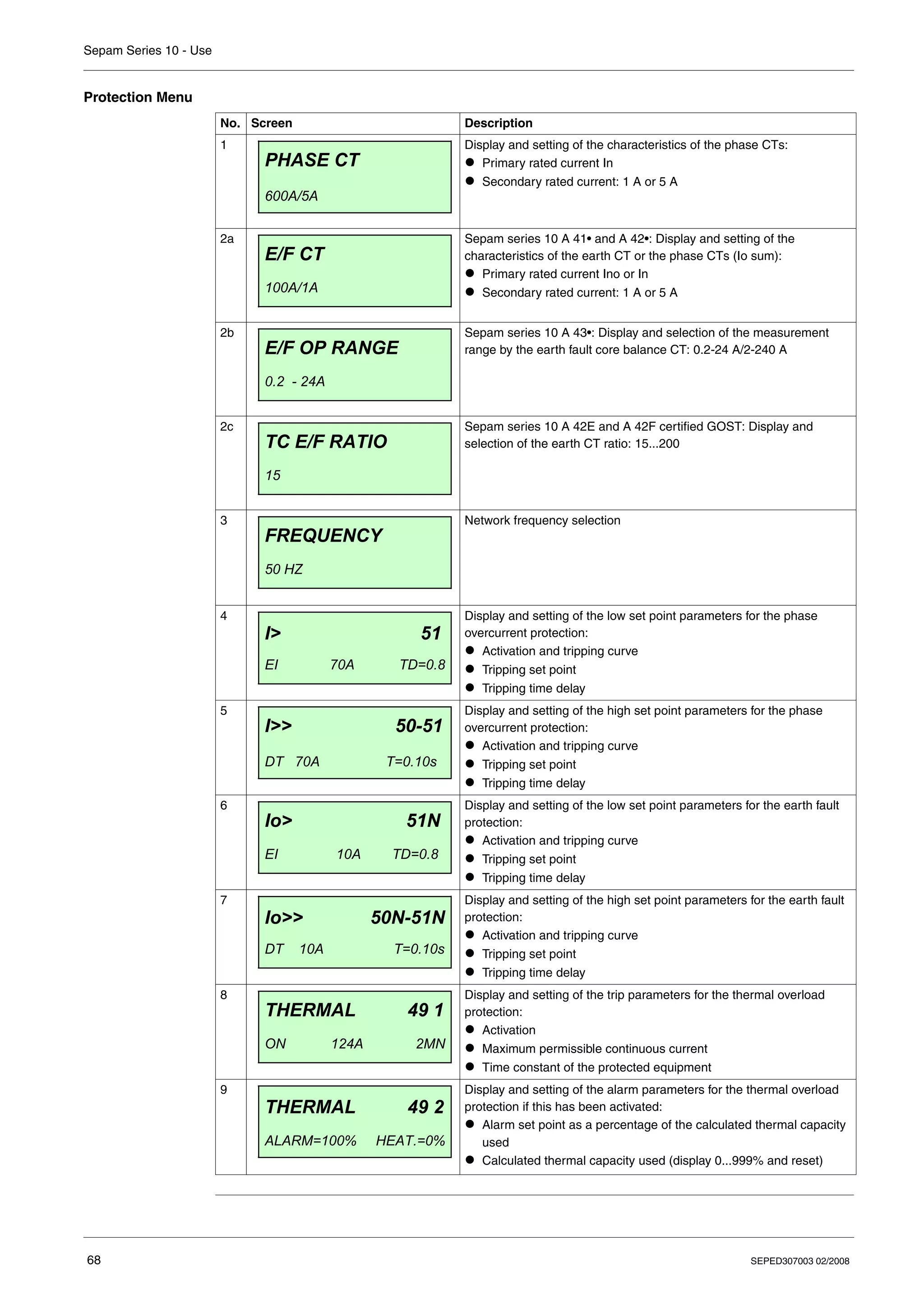

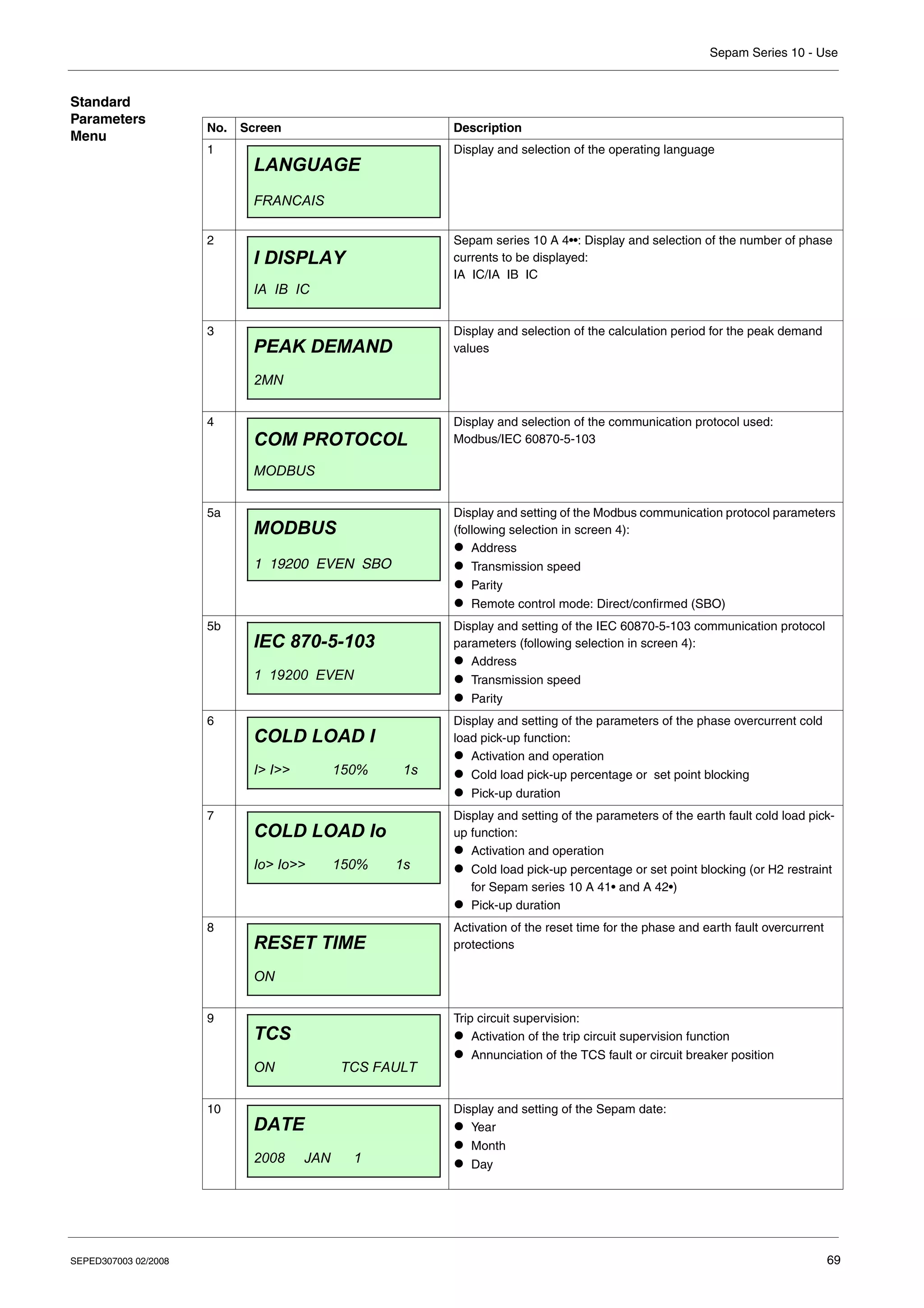

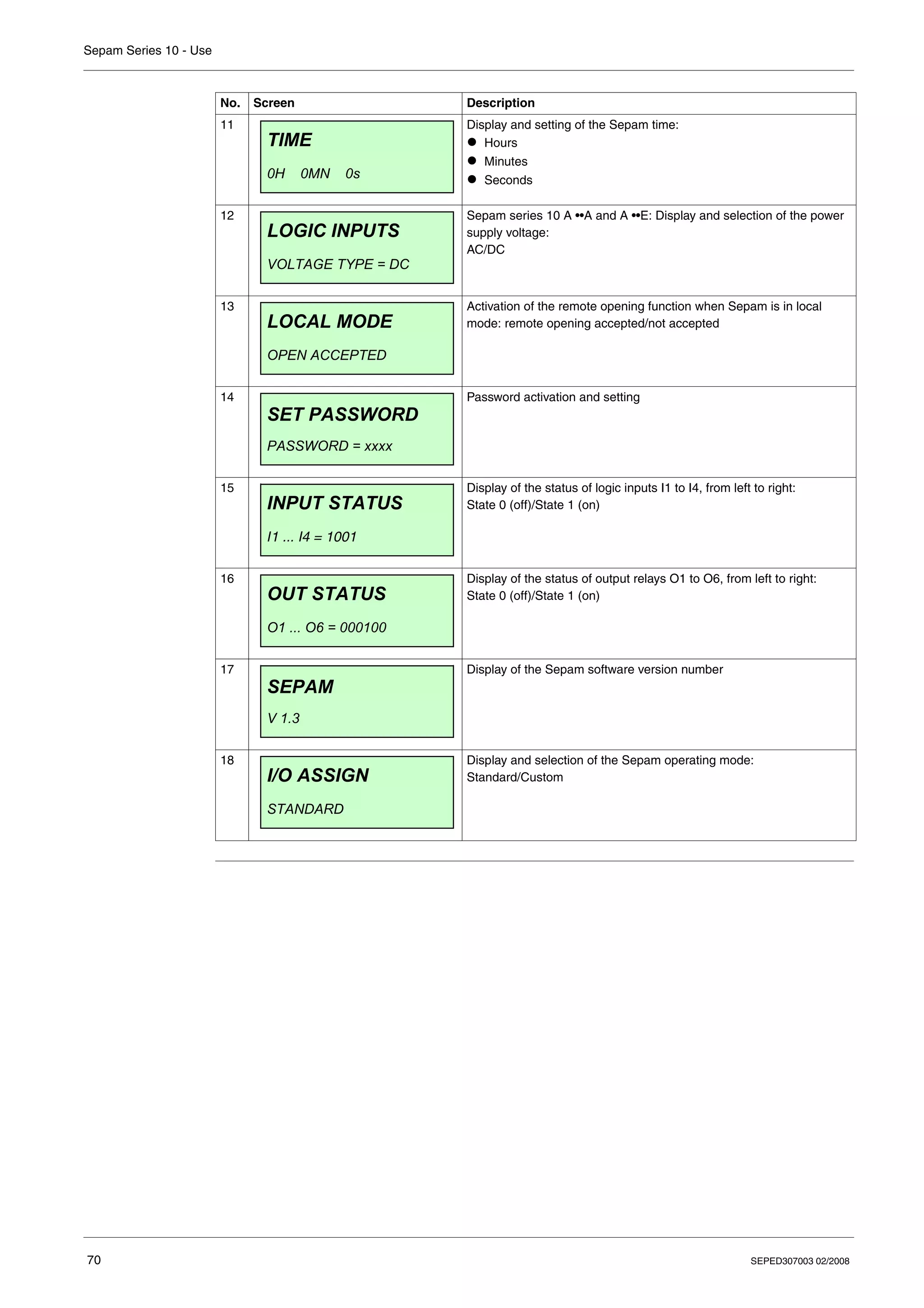

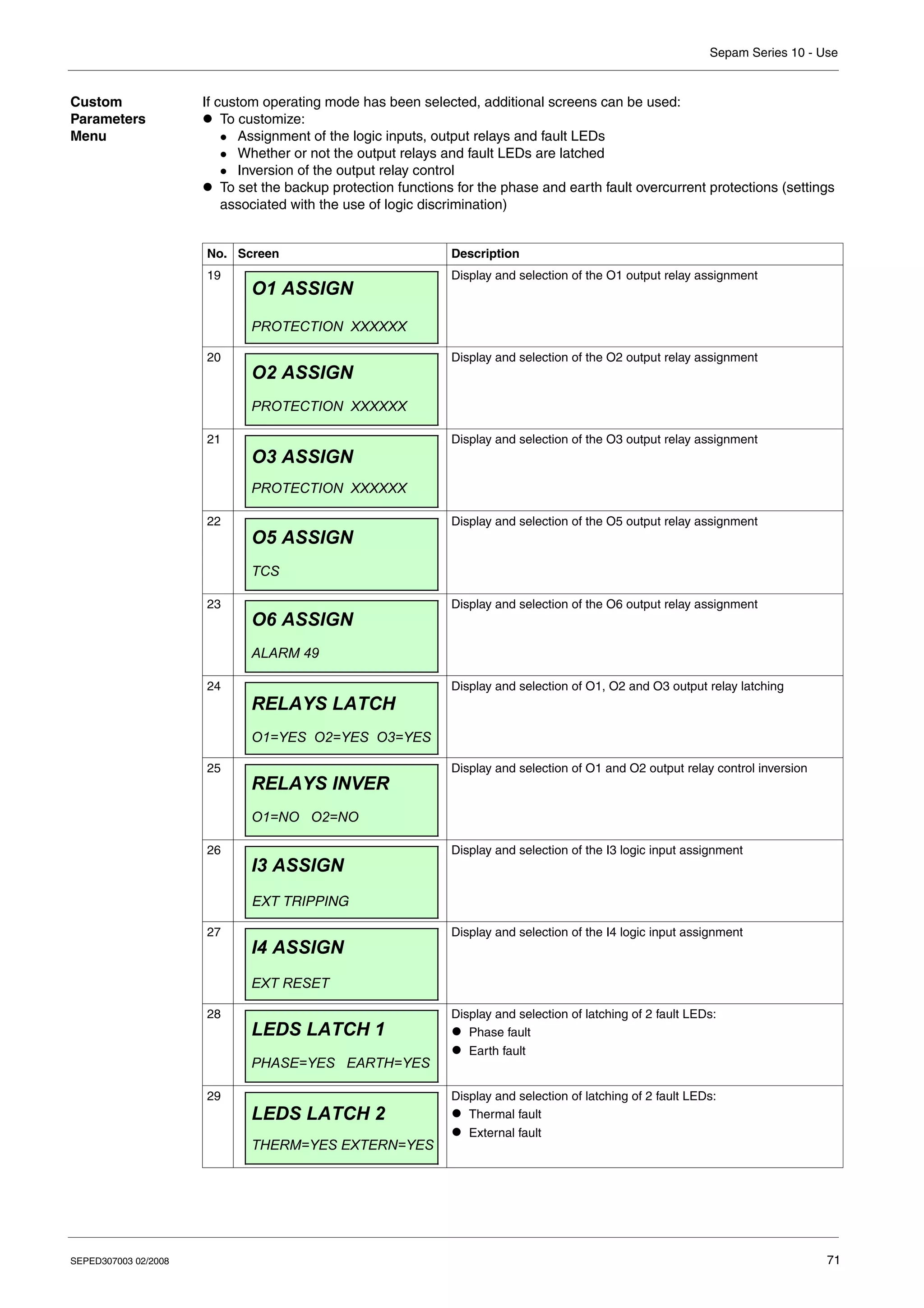

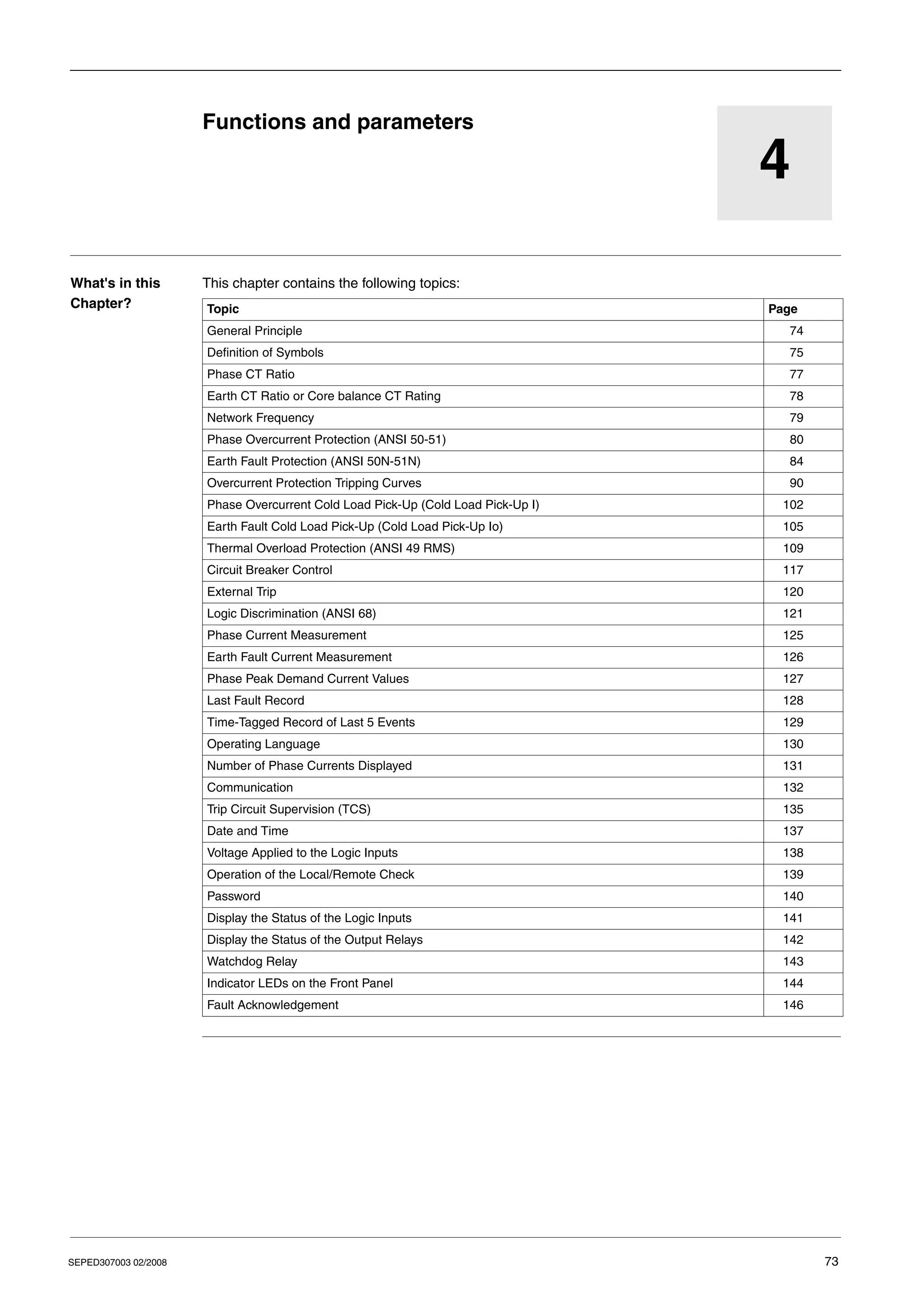

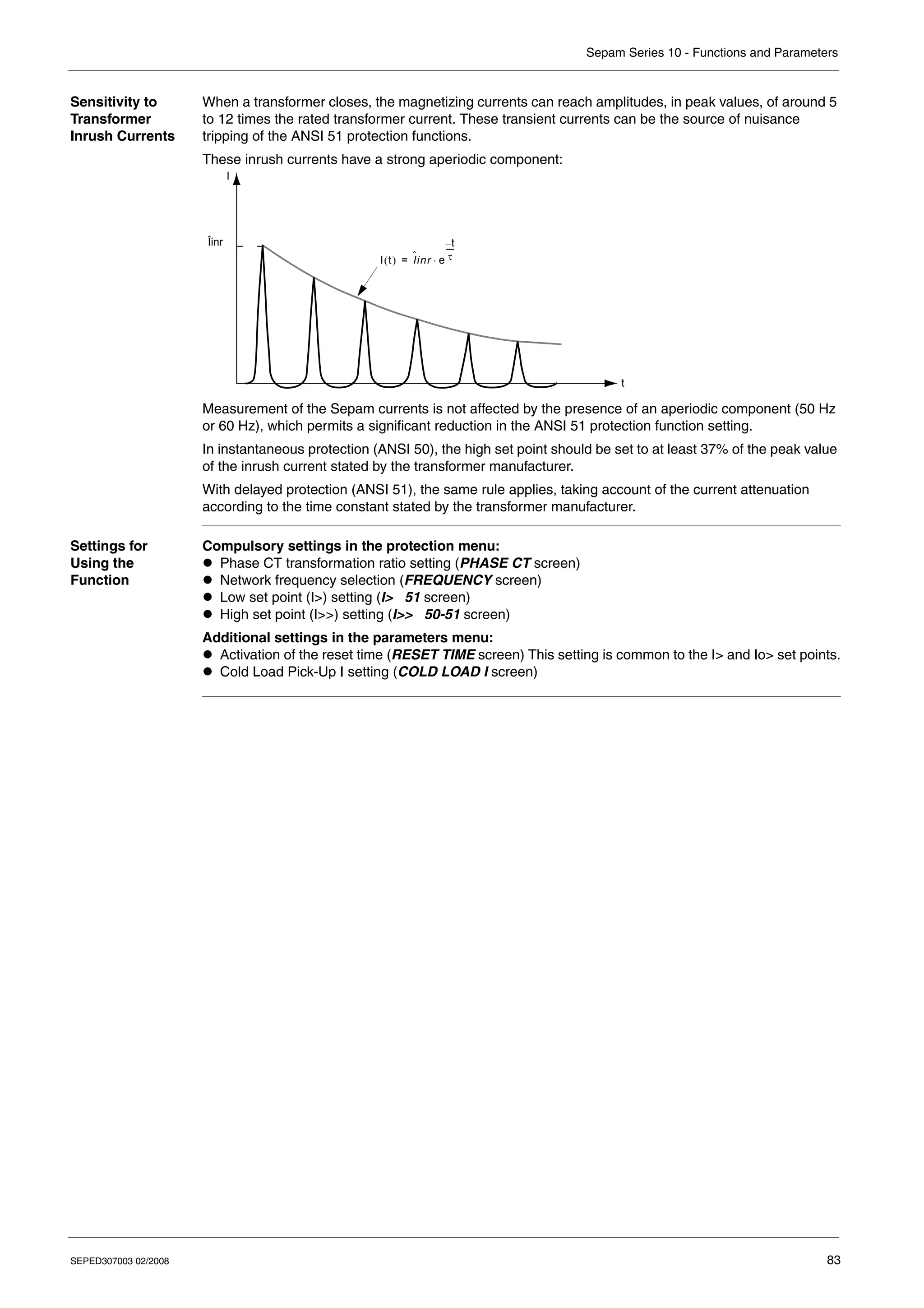

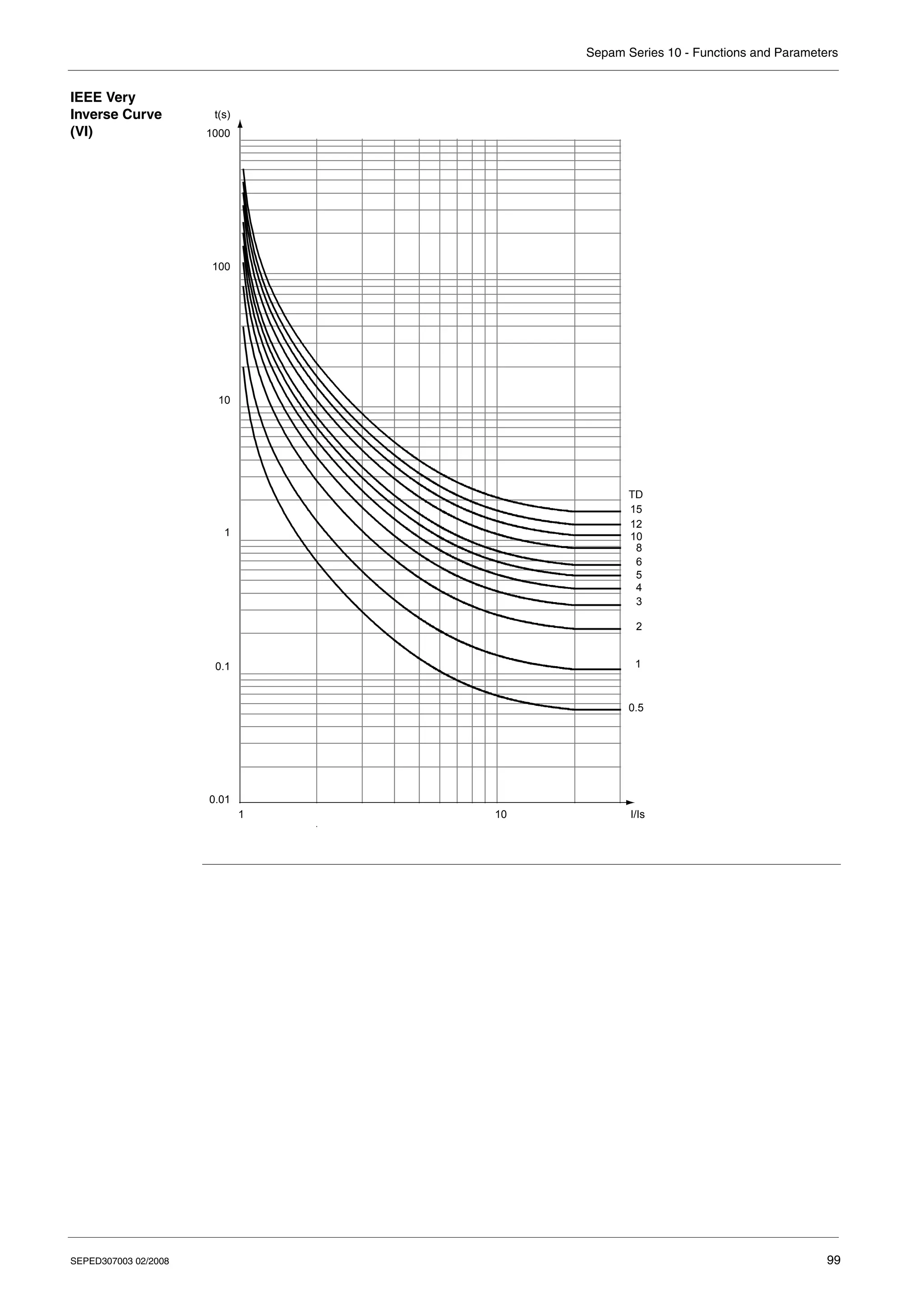

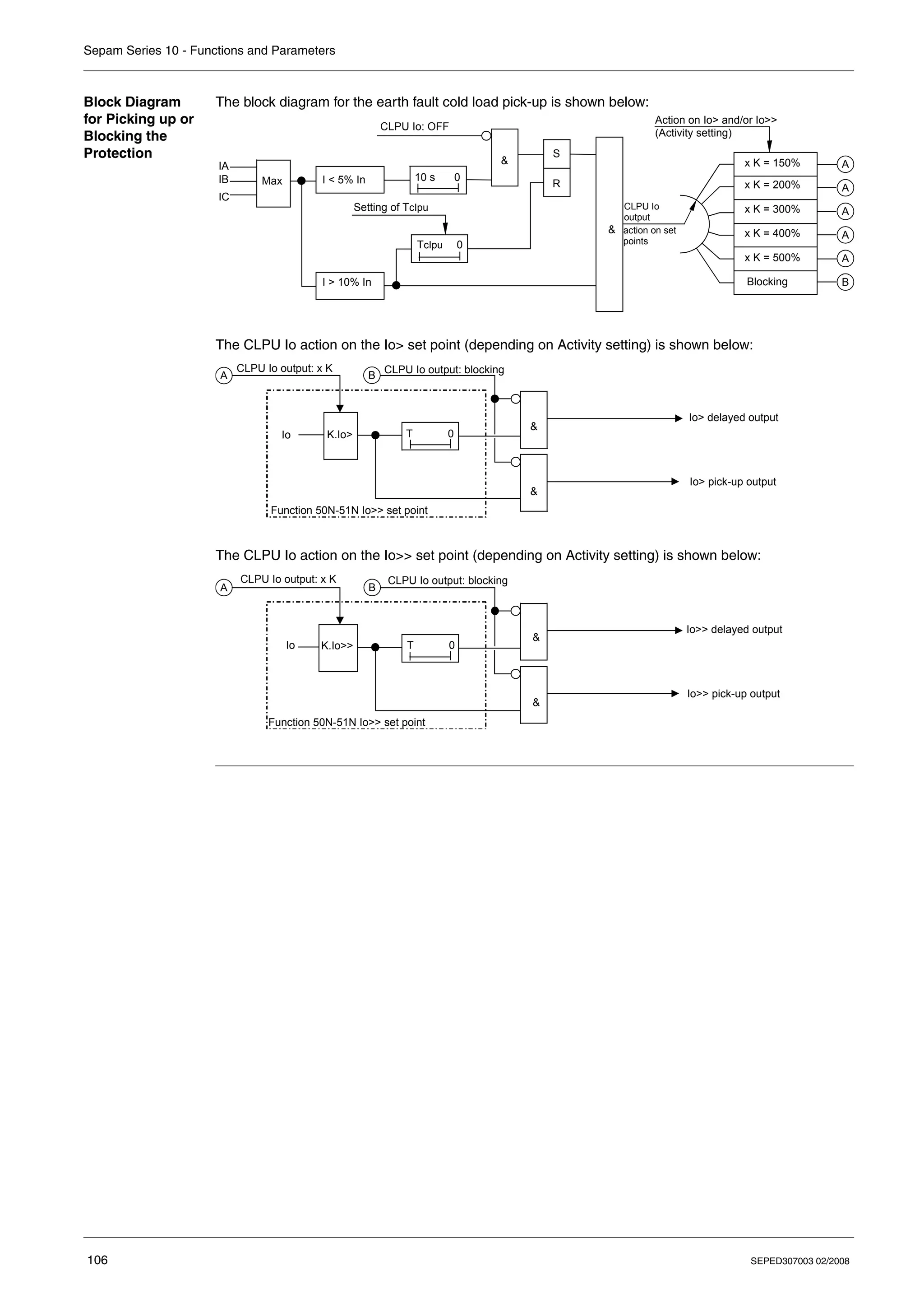

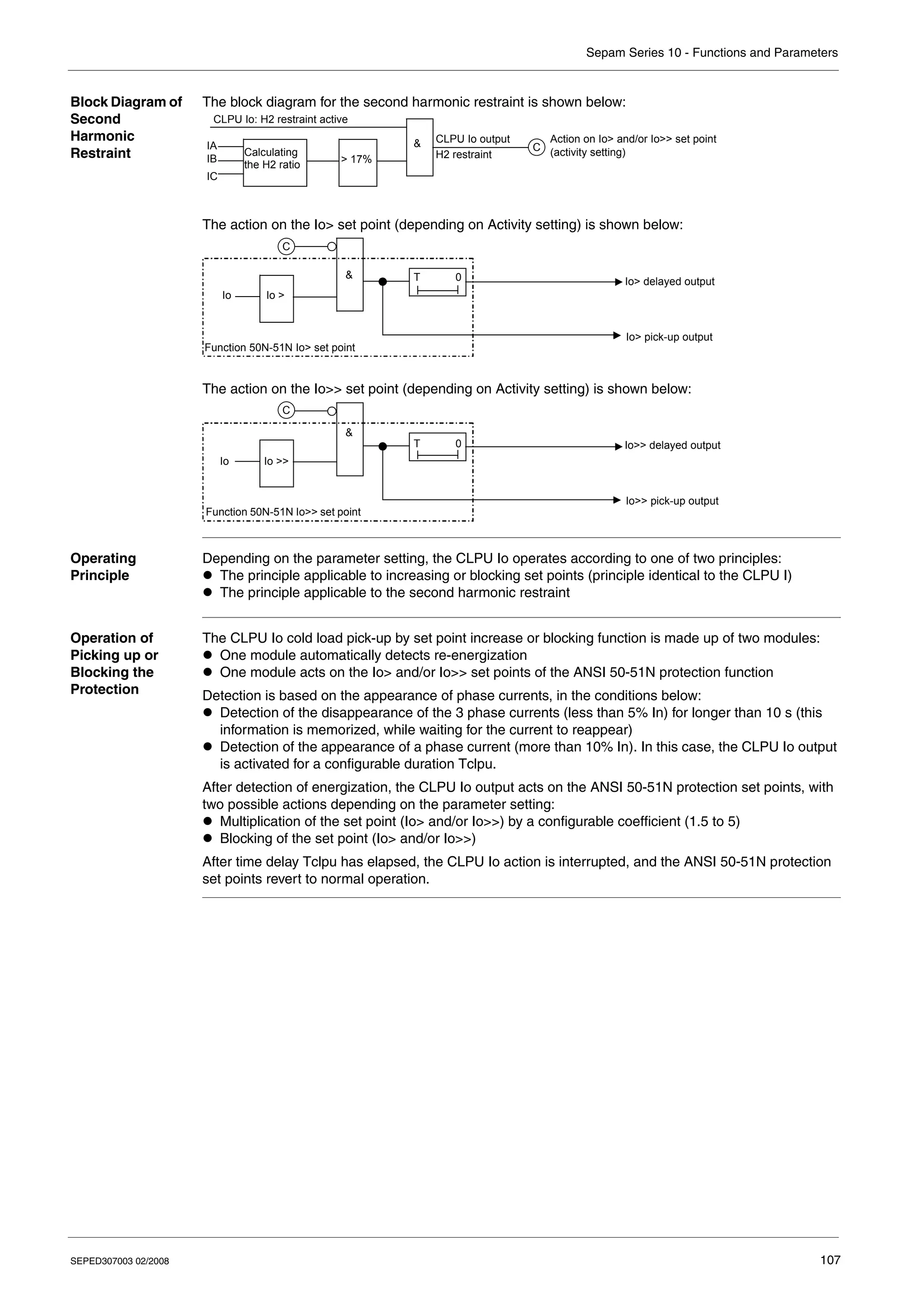

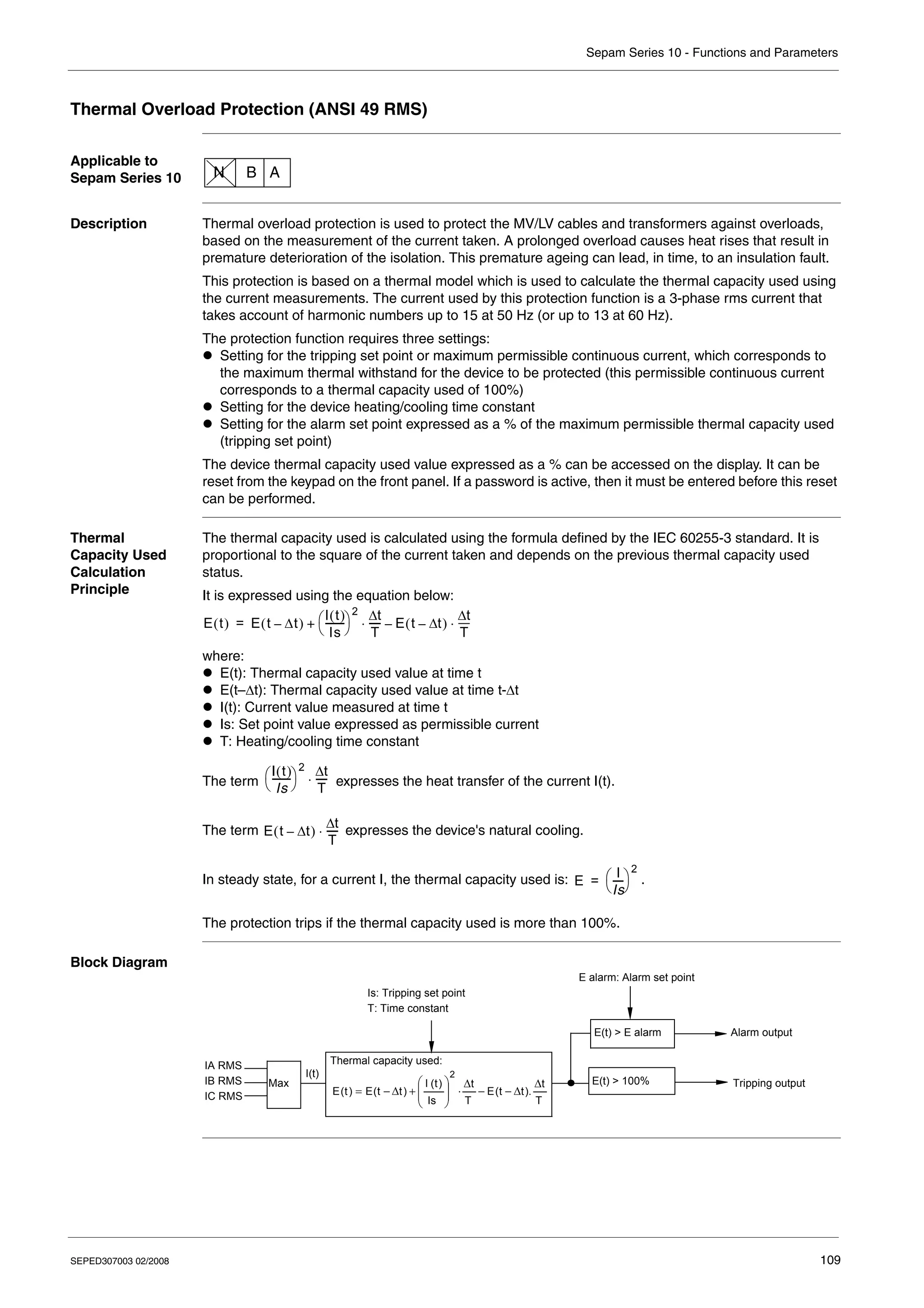

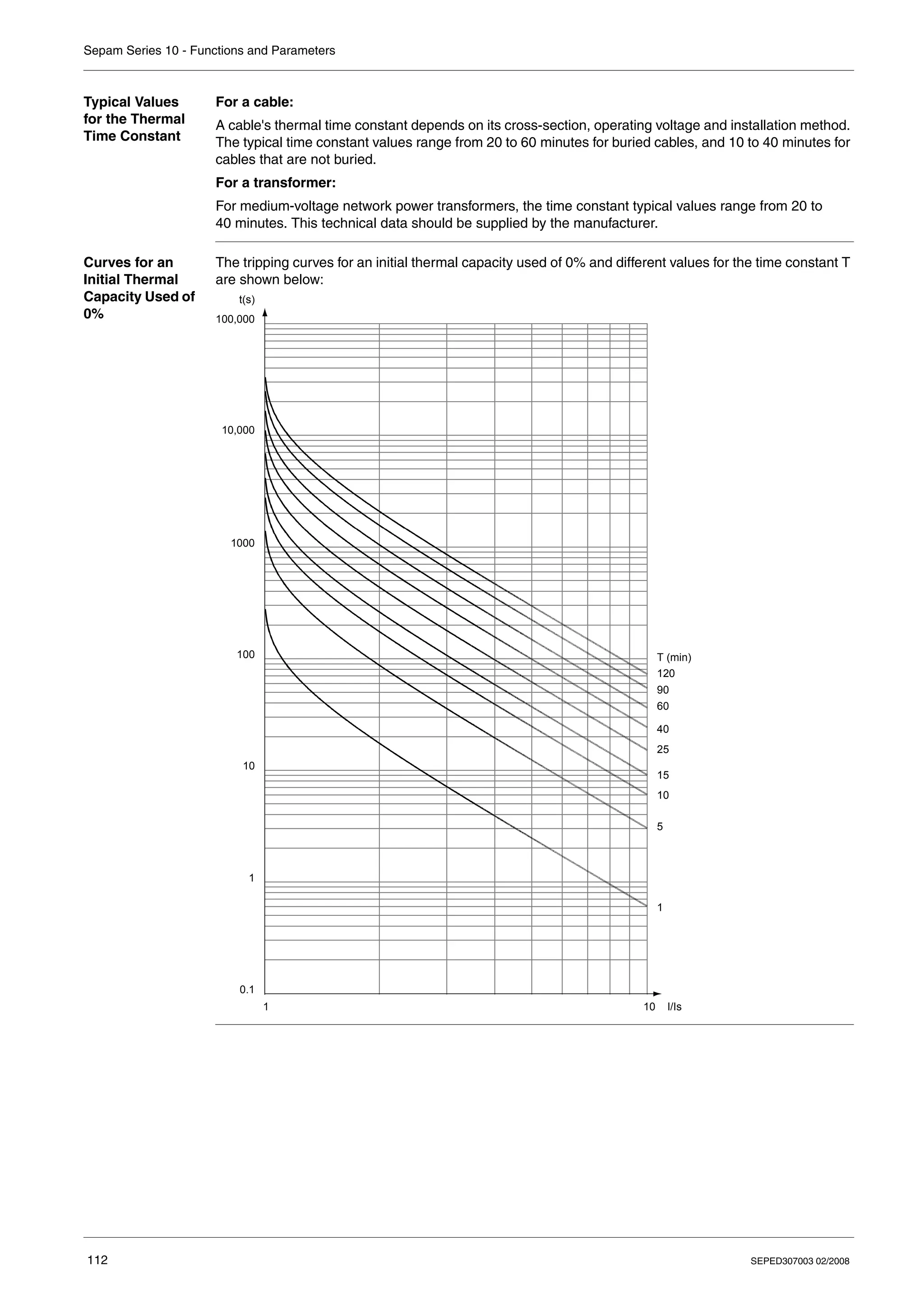

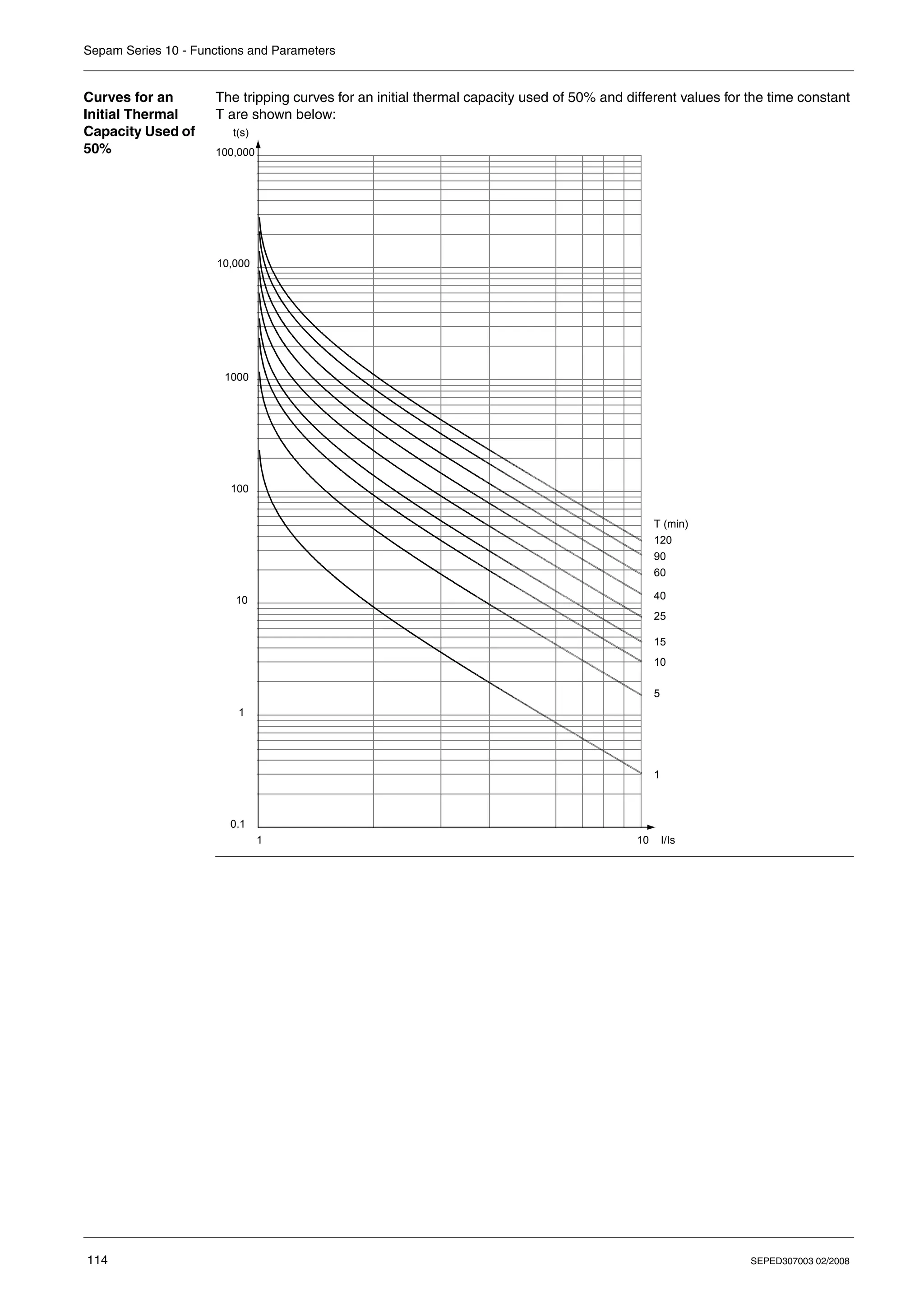

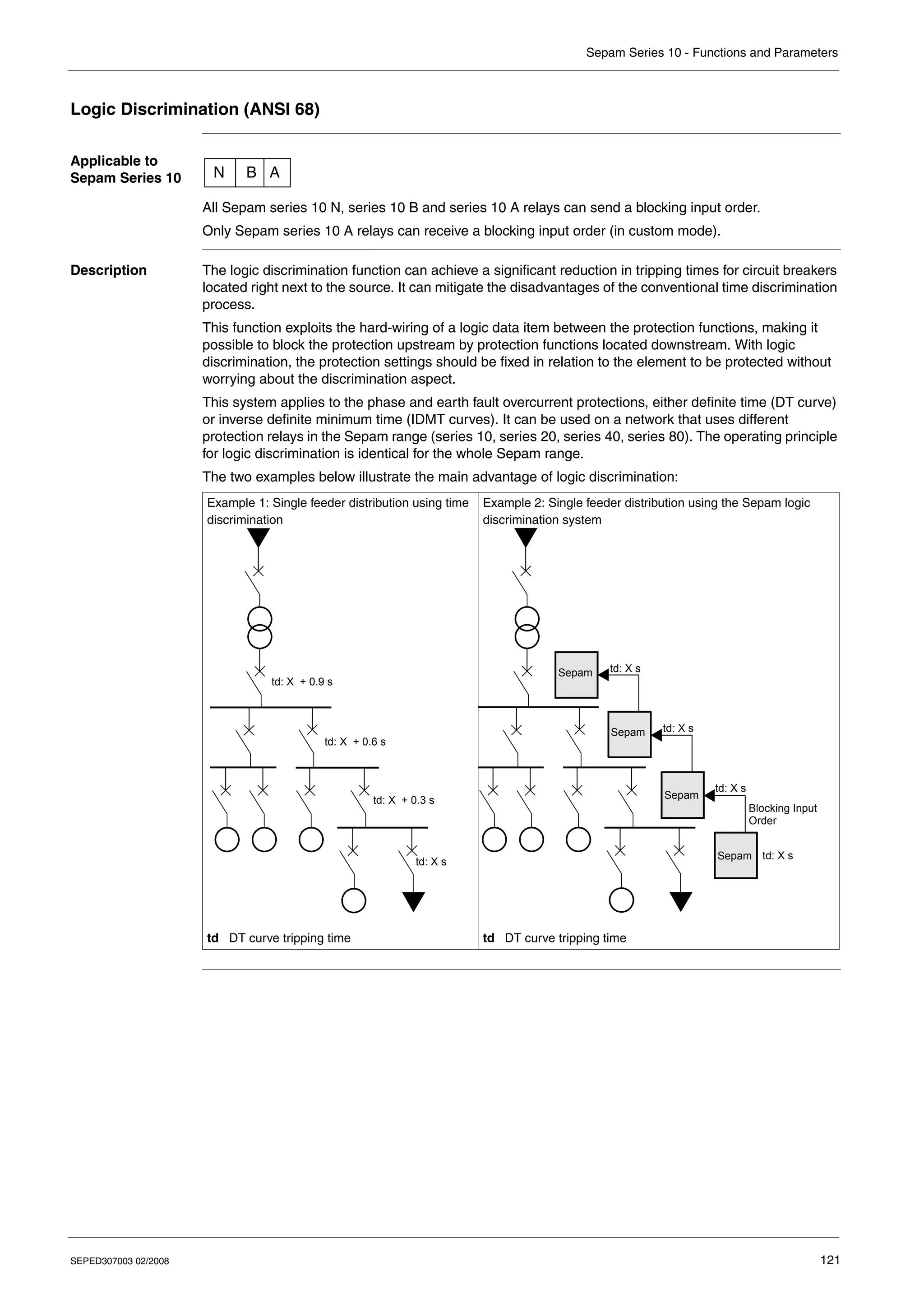

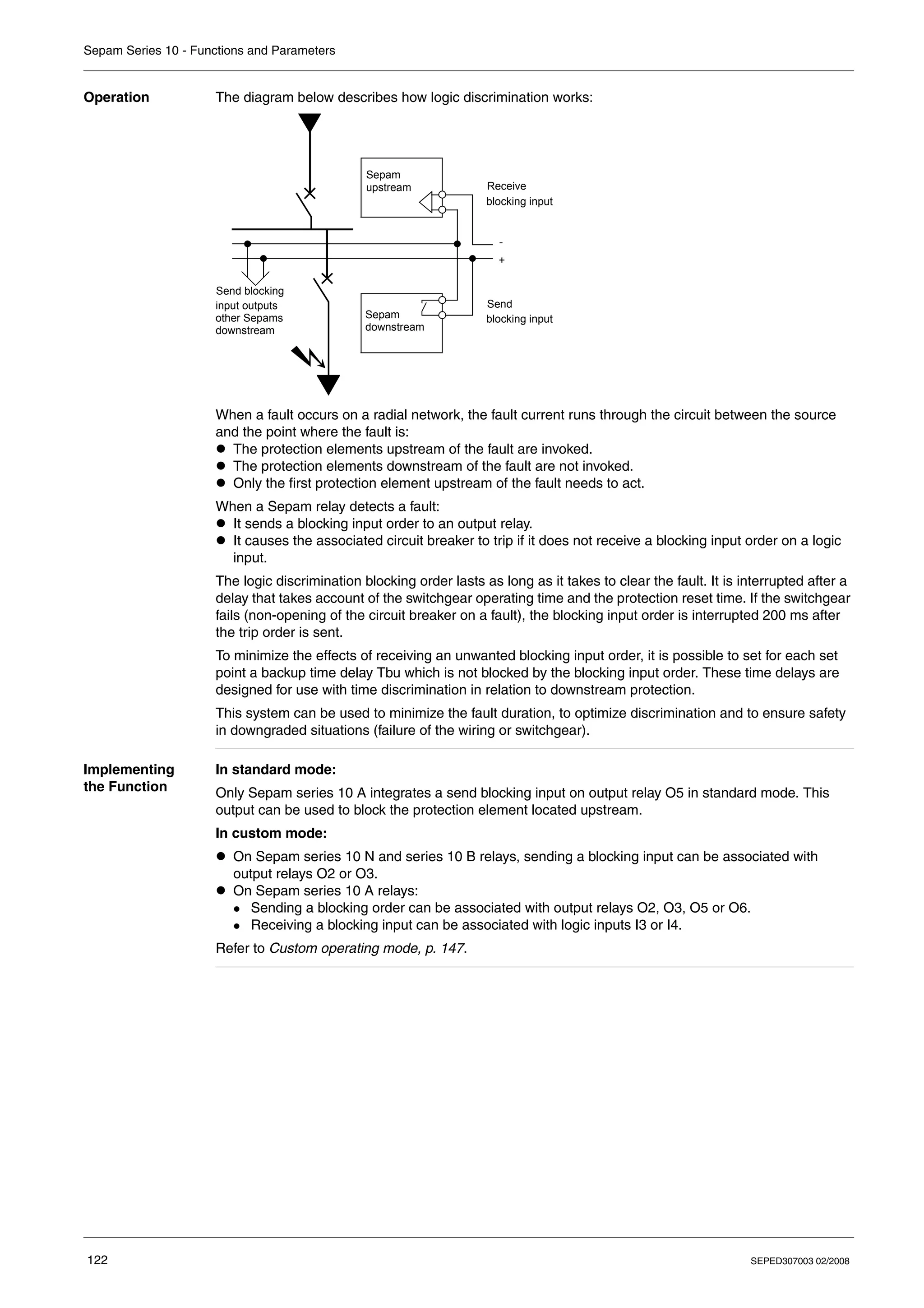

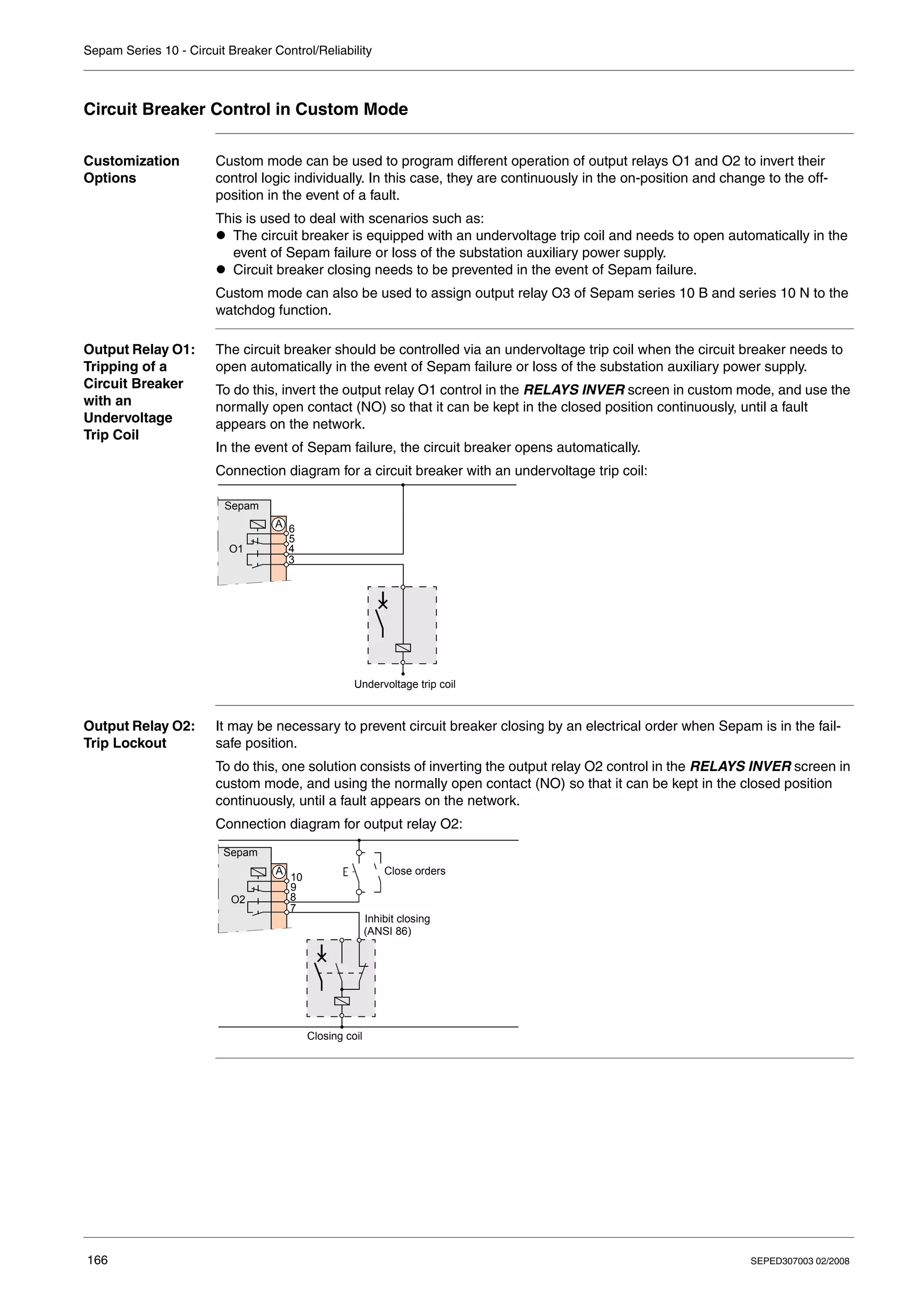

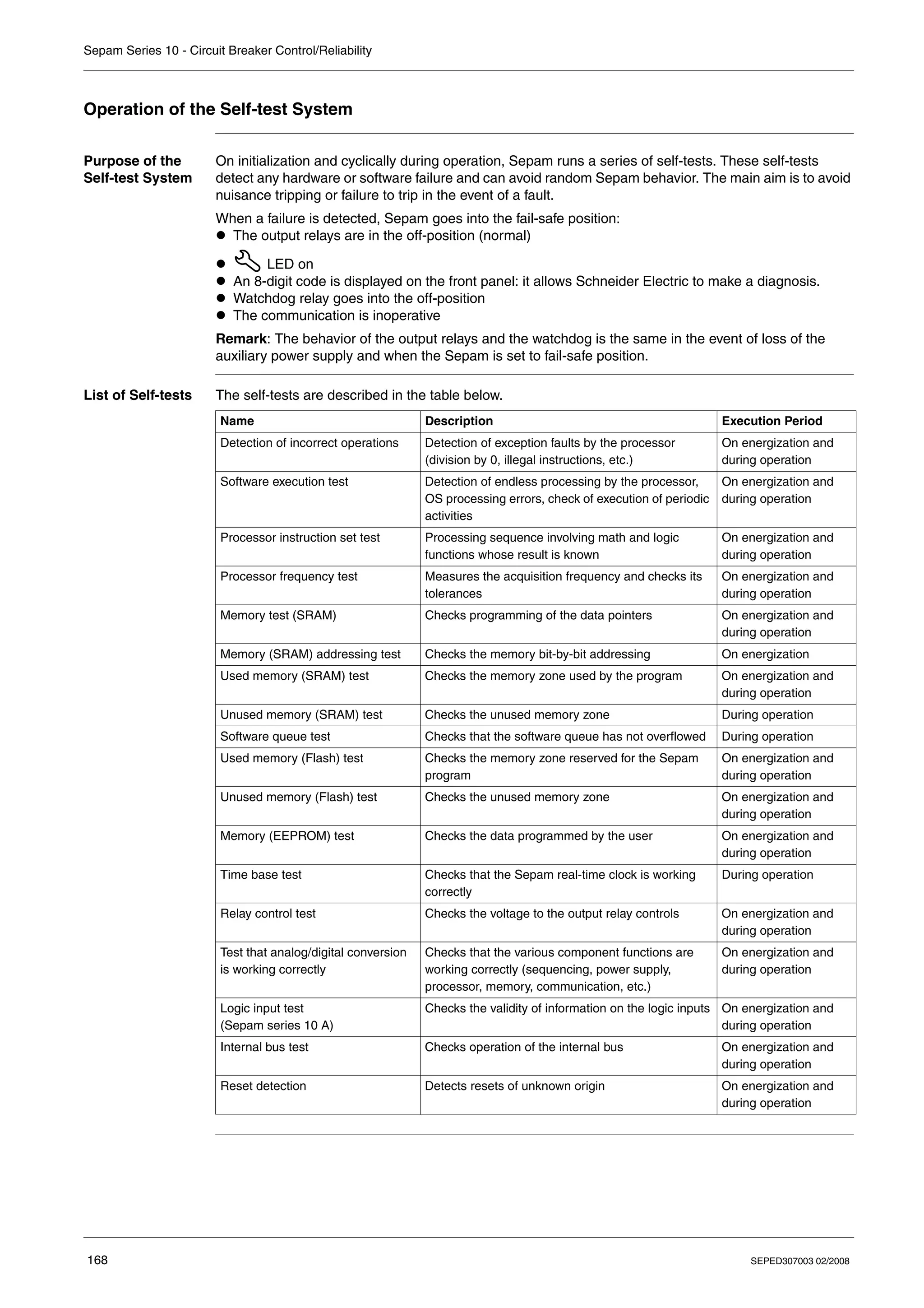

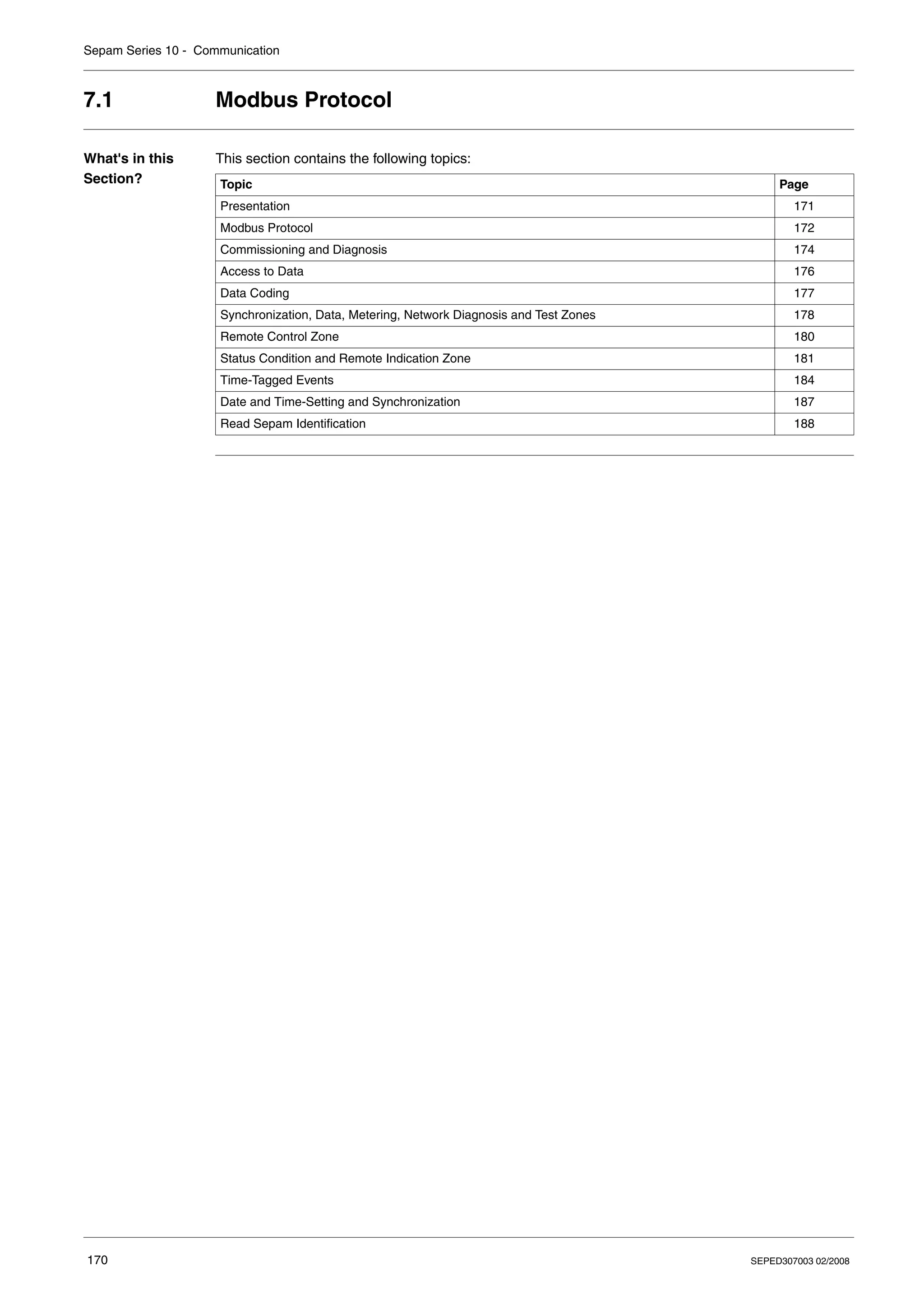

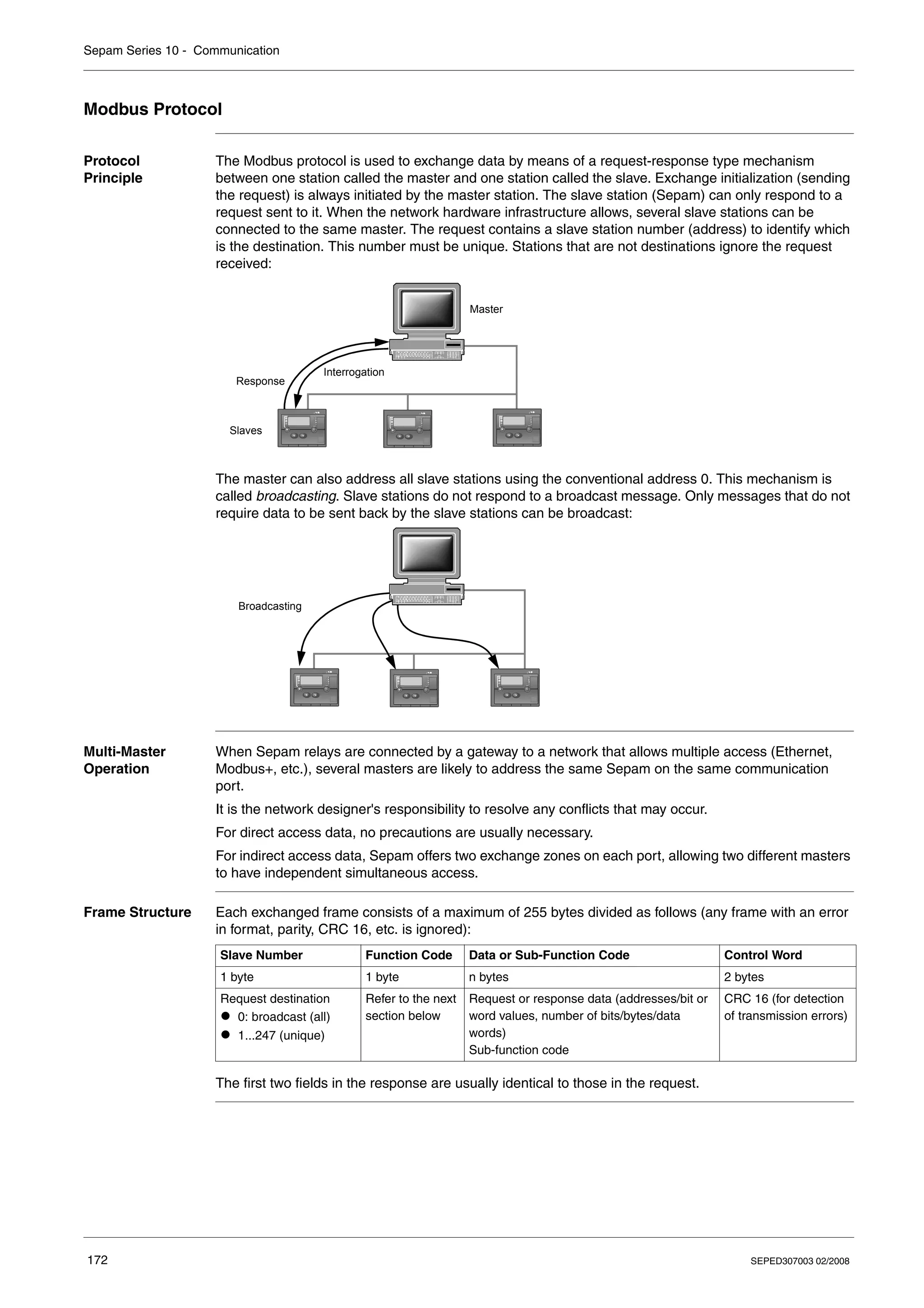

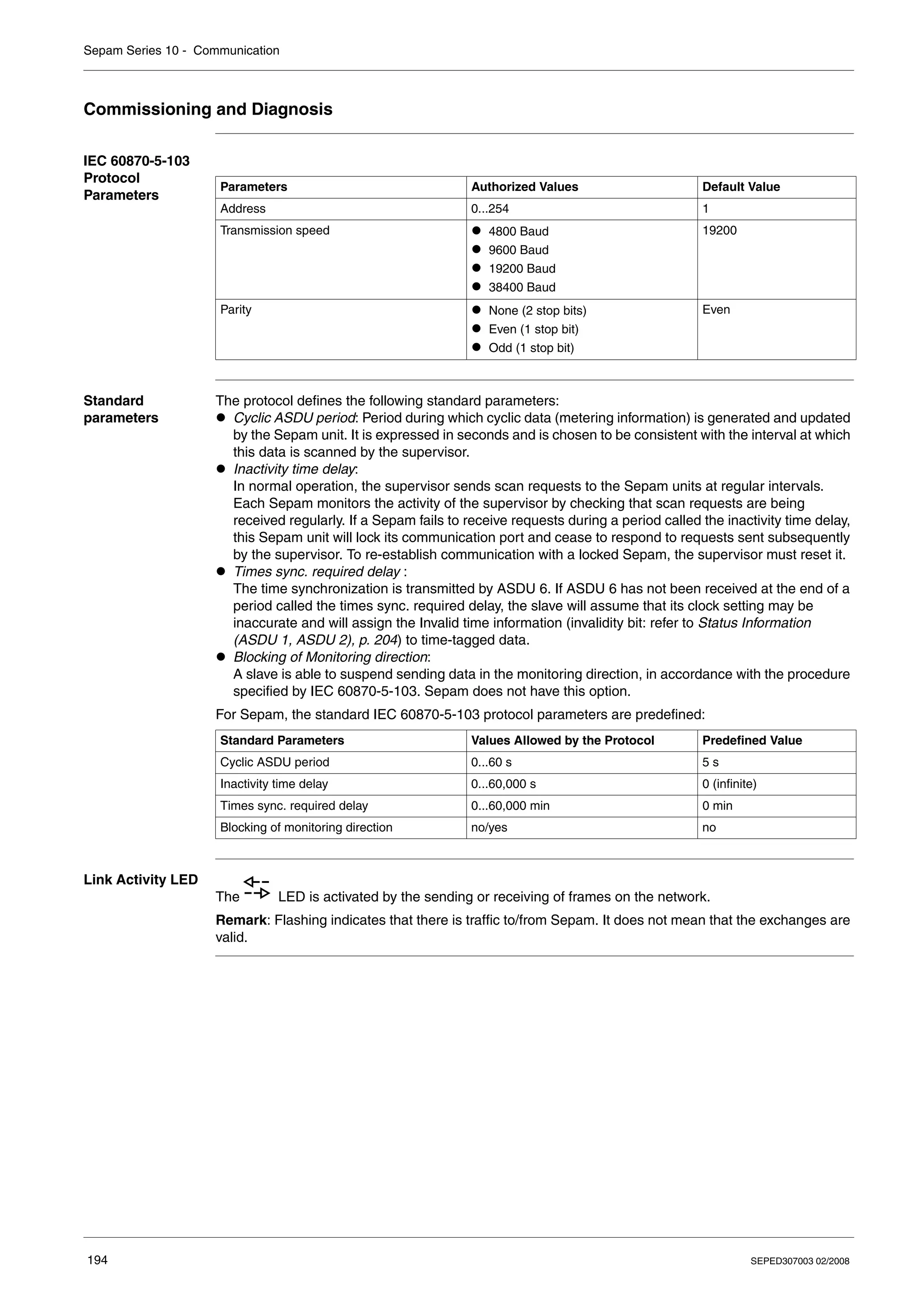

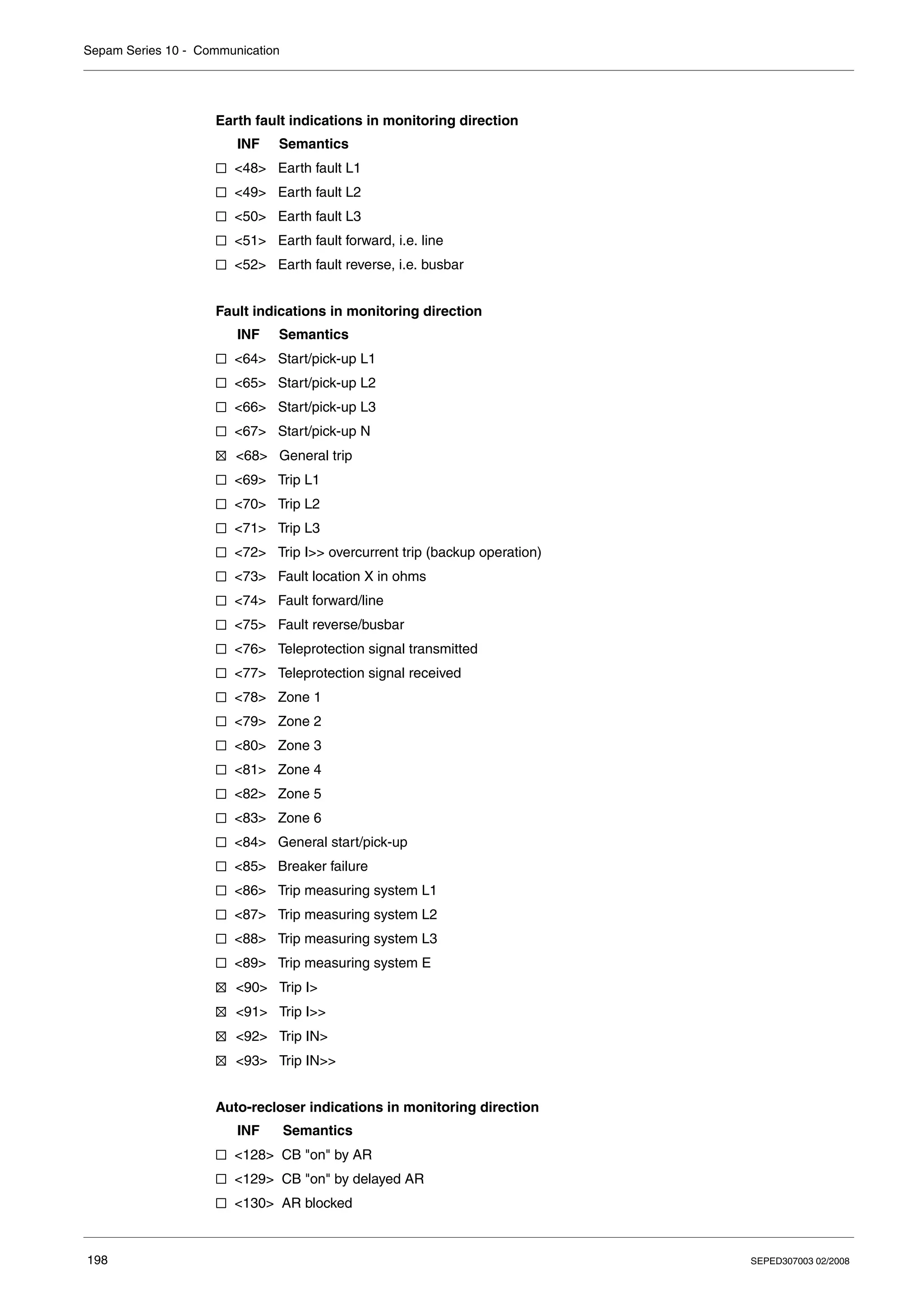

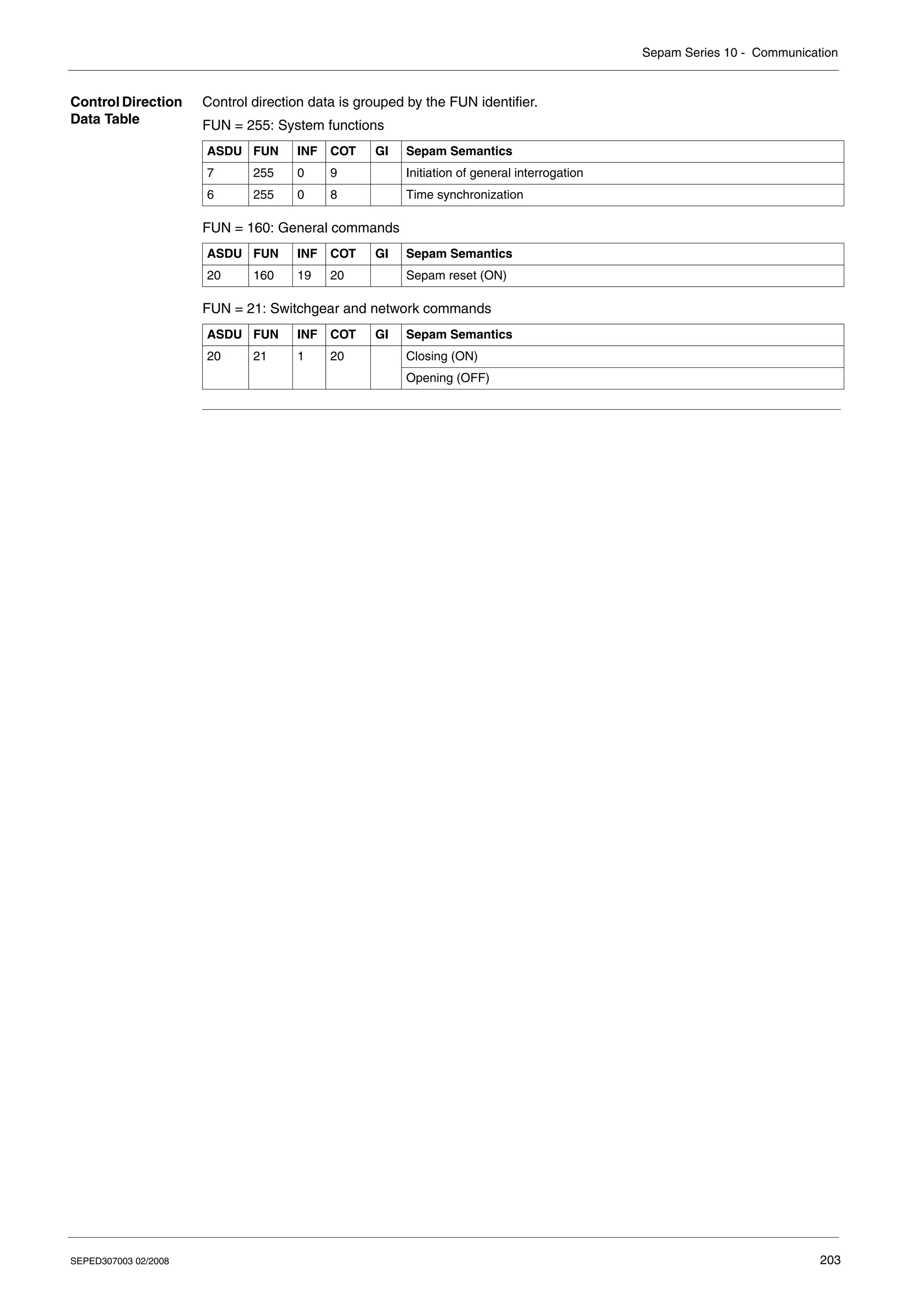

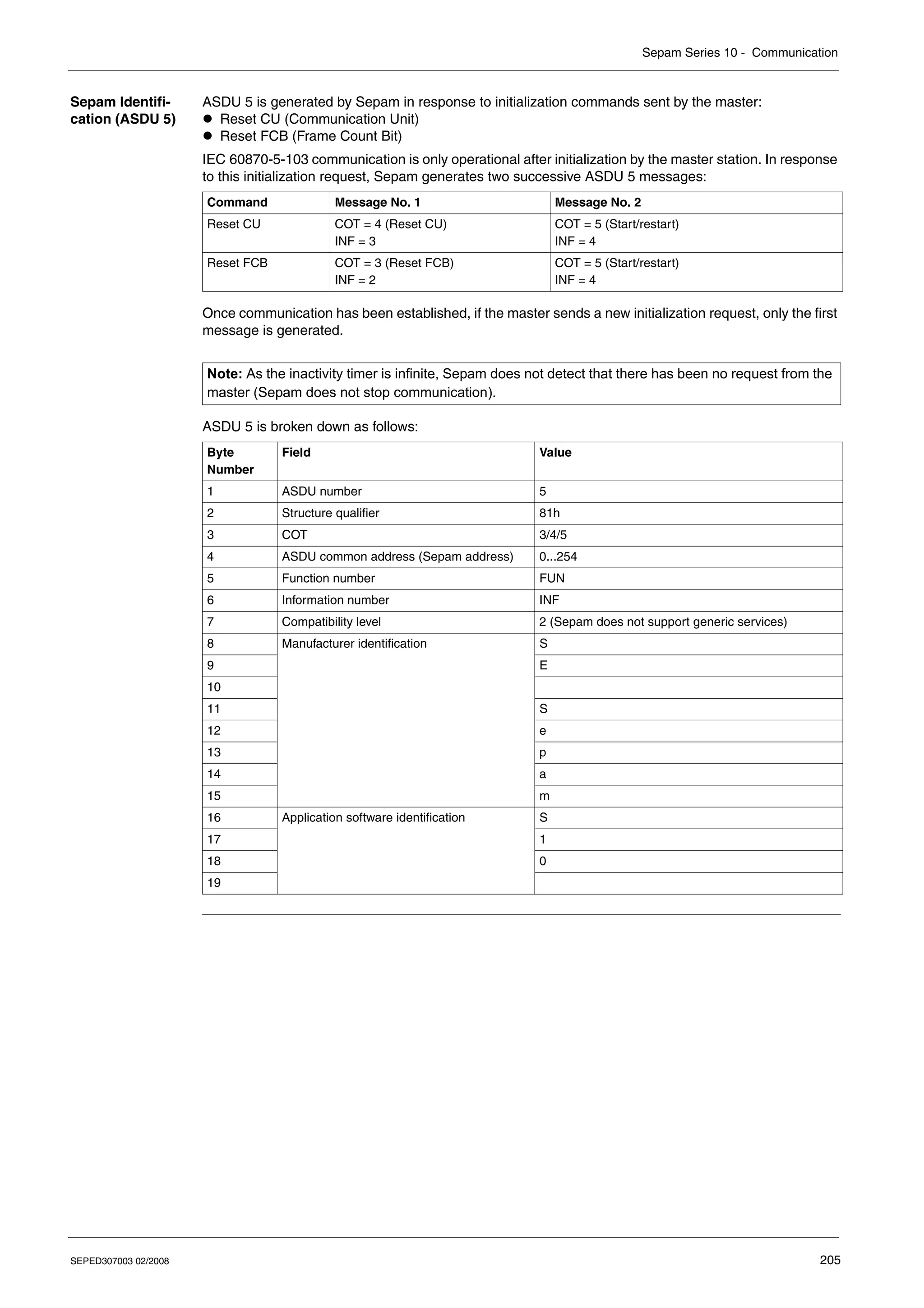

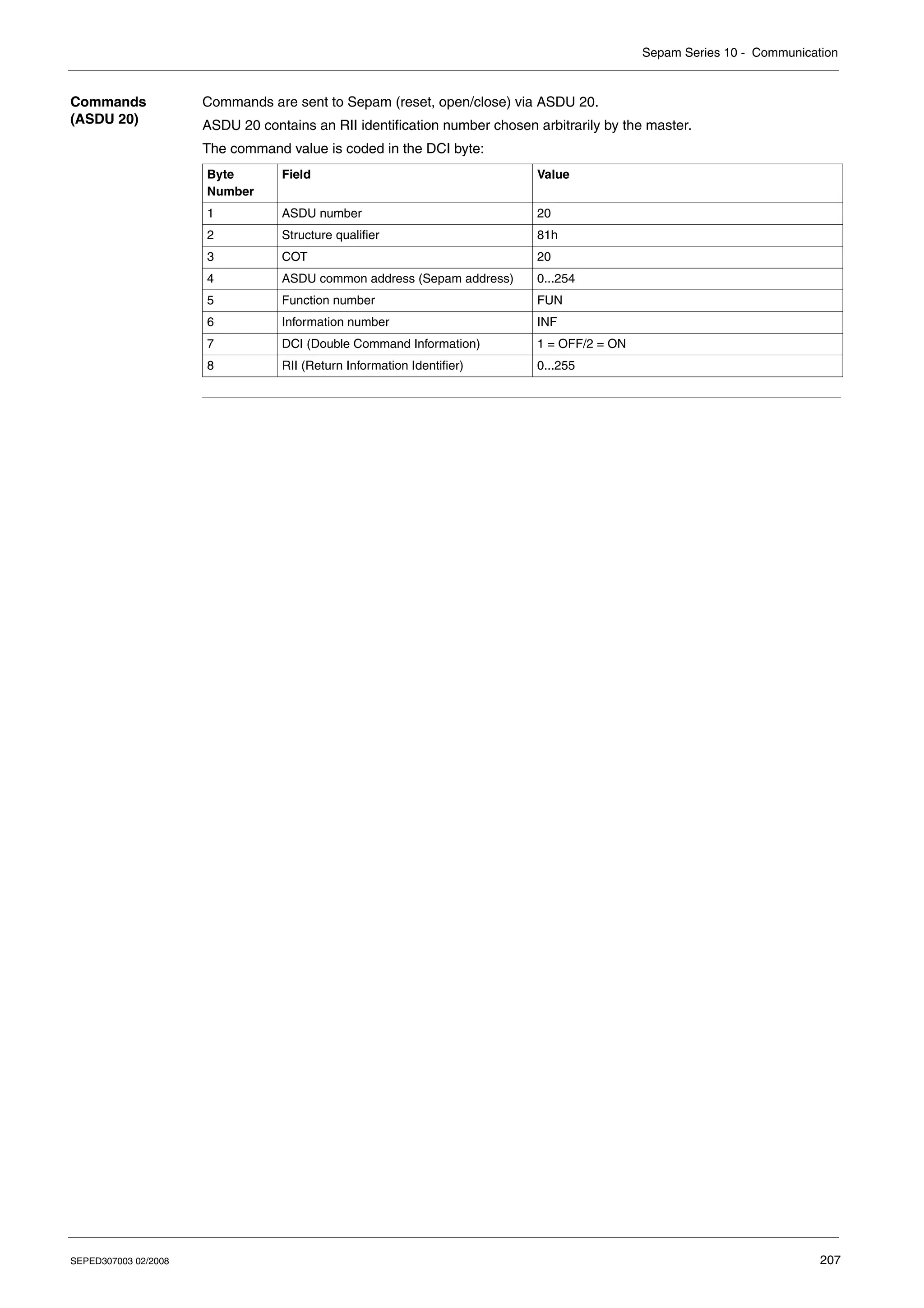

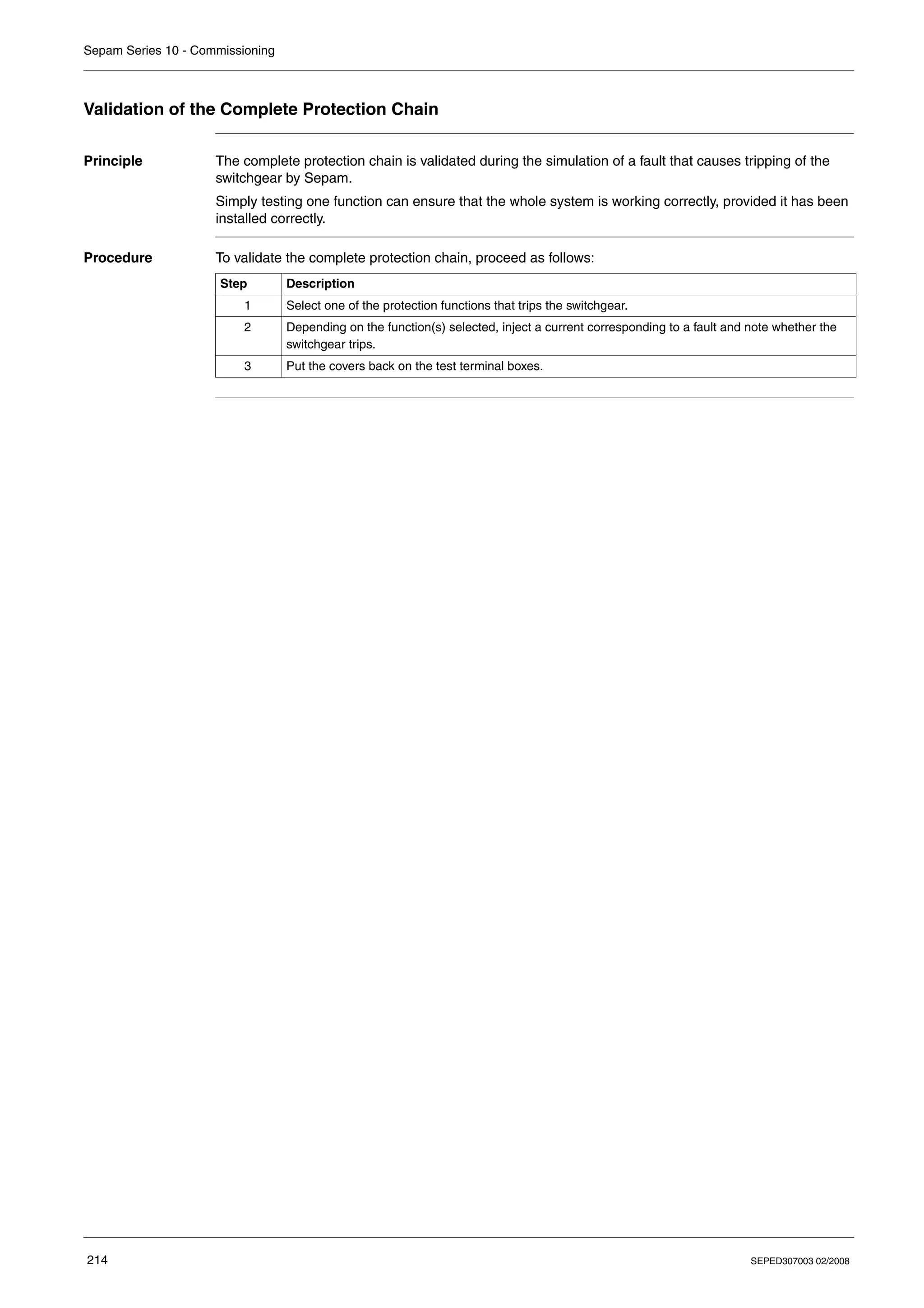

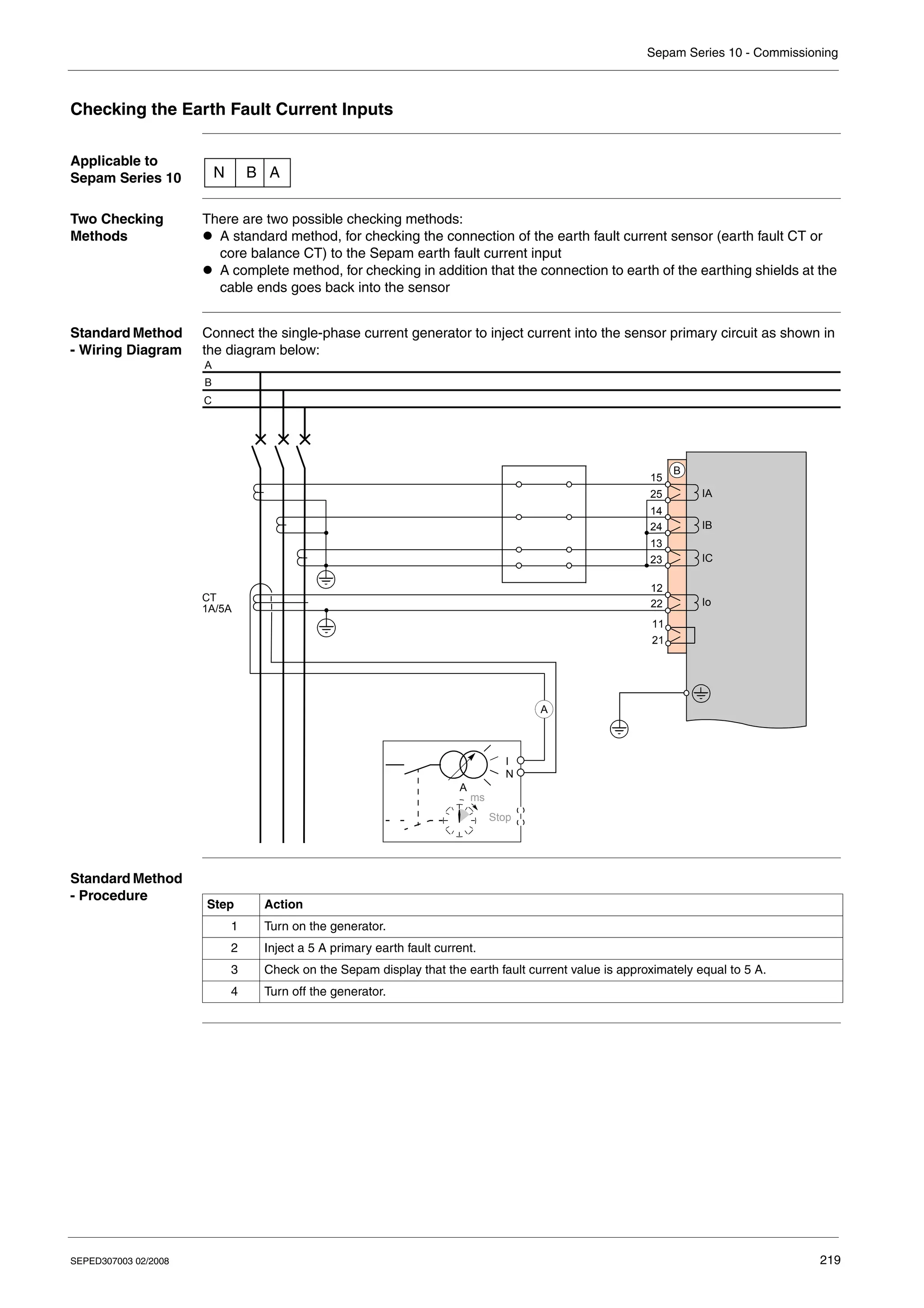

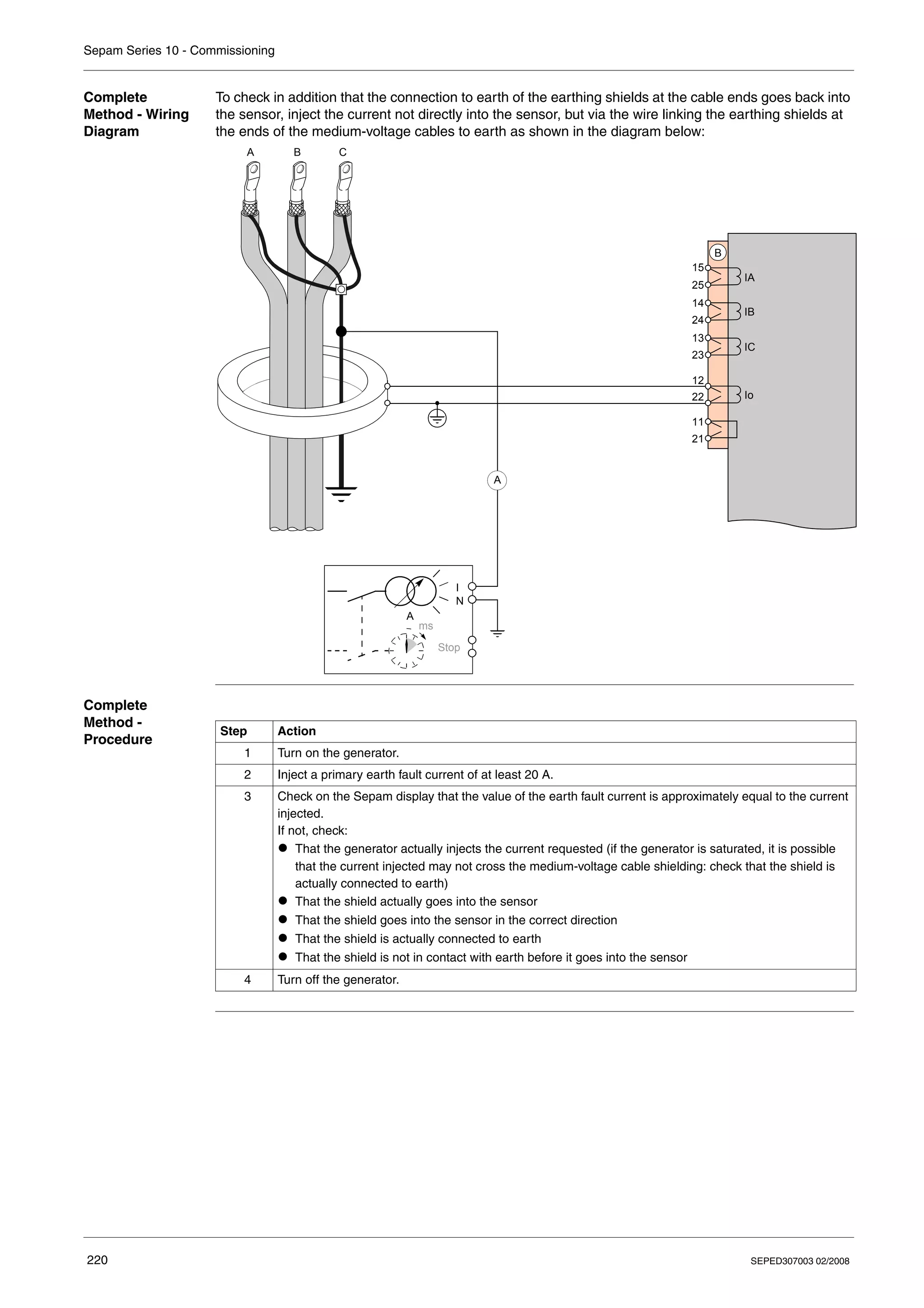

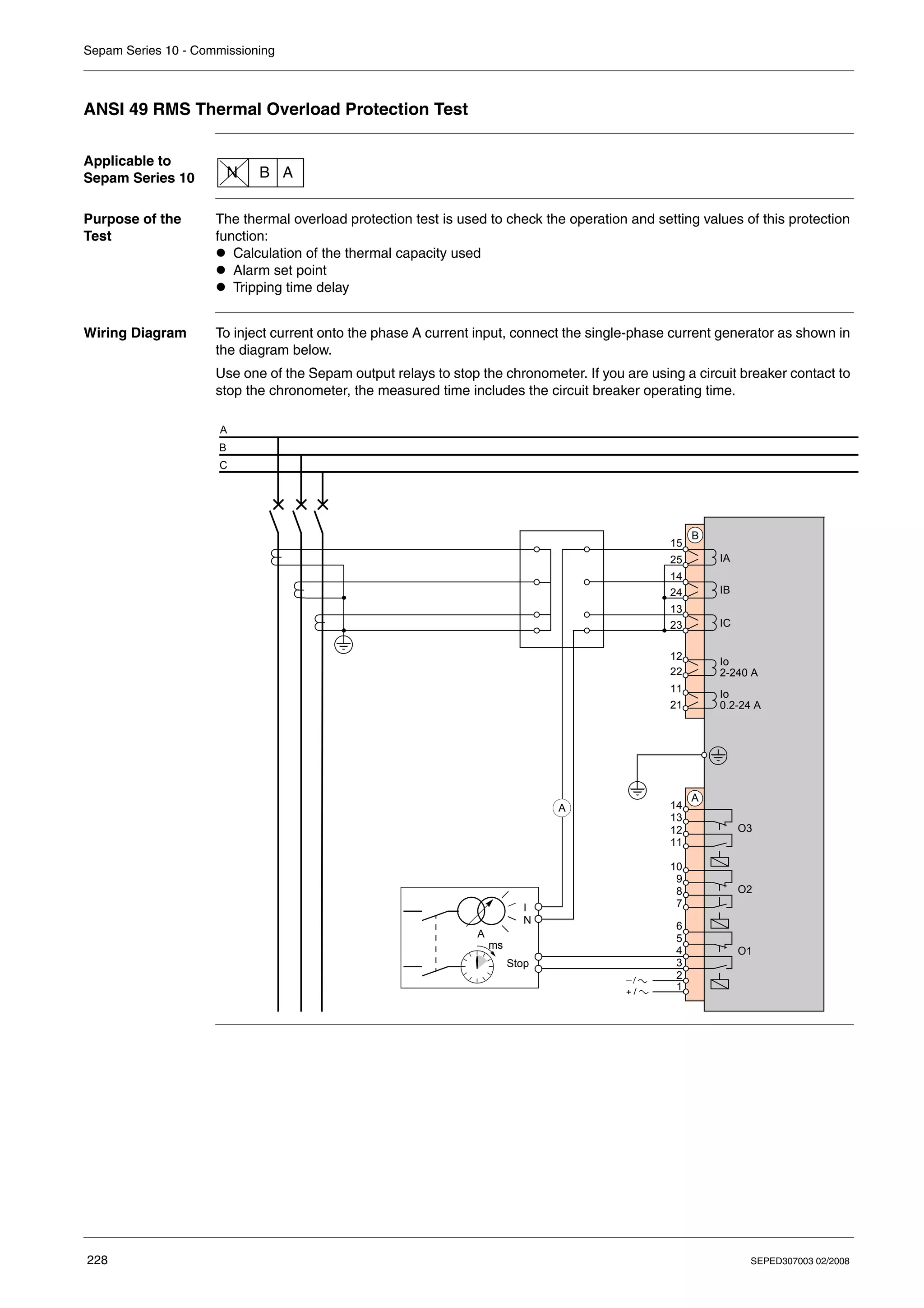

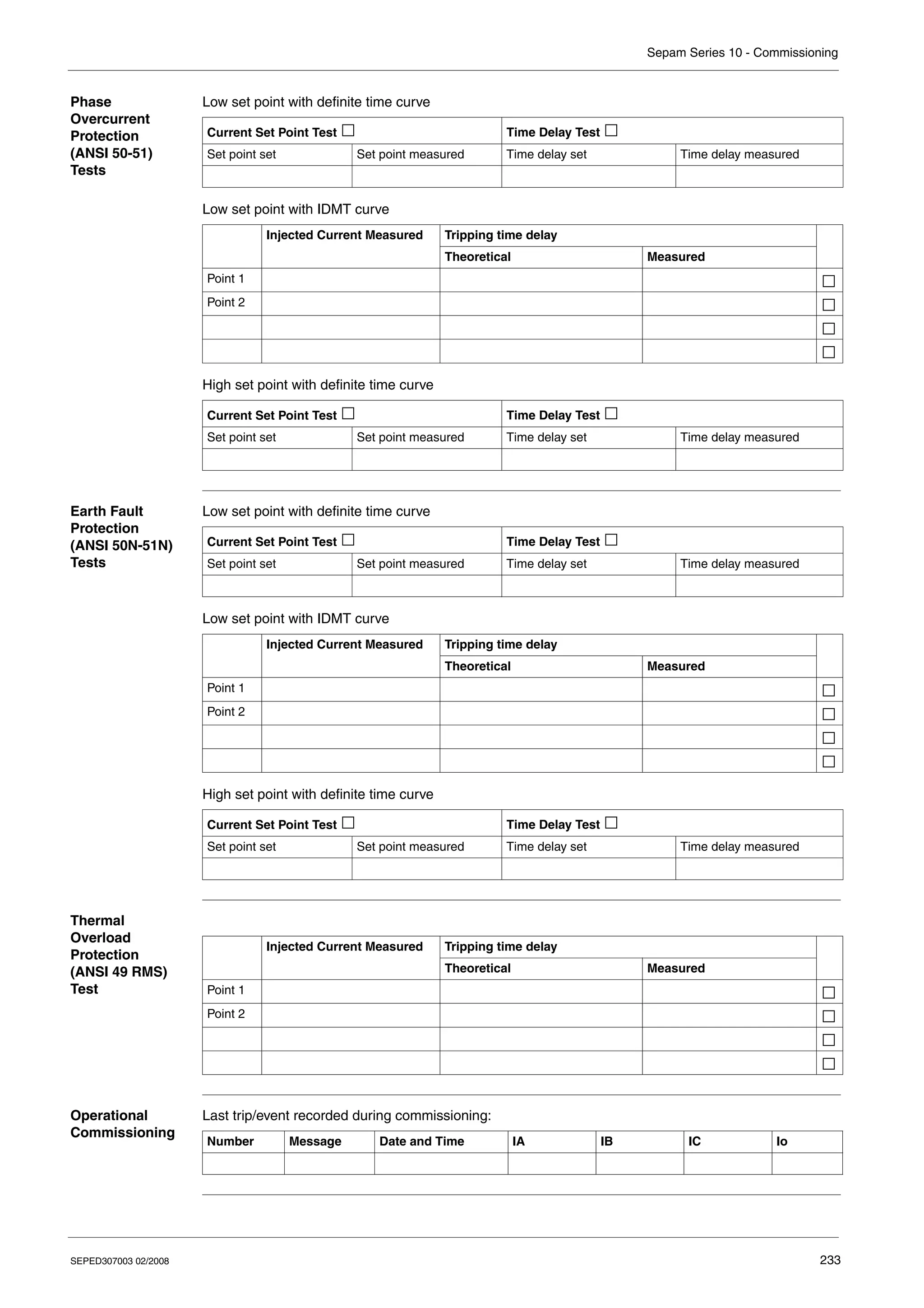

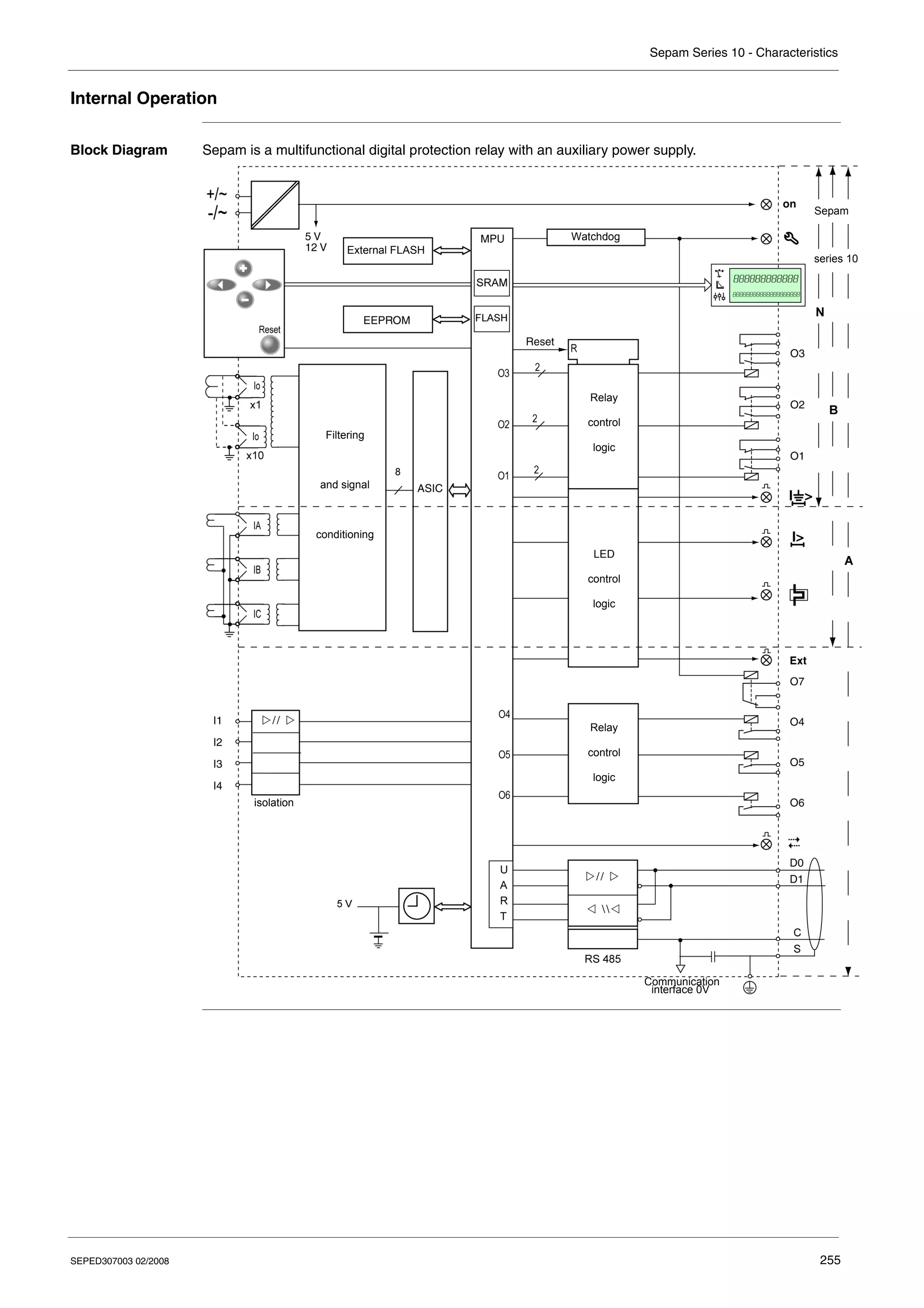

This document is a reference manual for Sepam series 10 electrical network protection devices produced by Hoang Phuong Company in Vietnam. It provides information on installation, operation, functions and parameters of the Sepam series 10 devices. The manual covers safety precautions, connecting current transformers and other inputs/outputs, setting protection functions like overcurrent and earth fault protection, and descriptions of the device's screens and parameters.