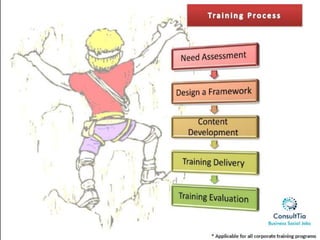

Consulttia is an Indian company founded in 2011 that focuses on process automation engineering and training, striving to deliver value to clients and exceed their expectations. The company offers a range of corporate training programs aimed at various aspects of process industries and engineering, with a commitment to international standards and continuous learning. Their approach emphasizes leadership in business and a supportive work environment for innovation and customer service.