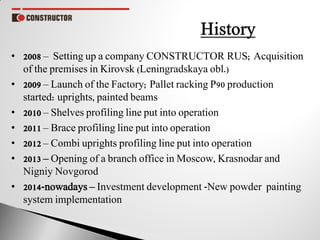

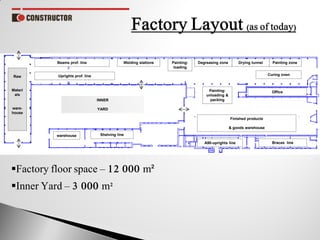

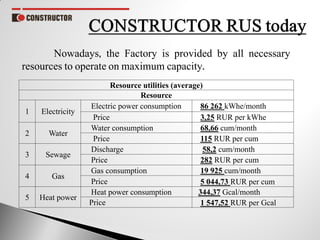

Constructor Rus, established in 2008 and located in Kirovsk, Russia, has grown into a significant supplier of storage and logistics solutions, with various production lines operational by 2014. The factory has invested in modernization and expansion, leveraging efficient construction and operational strategies. Today, it employs over 100 workers, occupies a 12,000 m² factory space, and utilizes various resources to maintain maximum operational capacity.