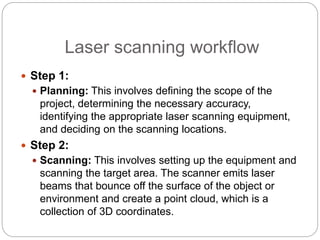

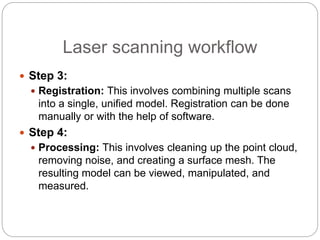

Construction laser scanning is a technology that utilizes lasers to create accurate 3D models of physical objects and environments, primarily used in the construction industry for quality control, BIM modeling, and progress monitoring. The document outlines various types of laser scanning, equipment, workflow stages, and highlights challenges such as cost and data management. It also discusses future developments aimed at improving speed, resolution, and integration with other technologies.