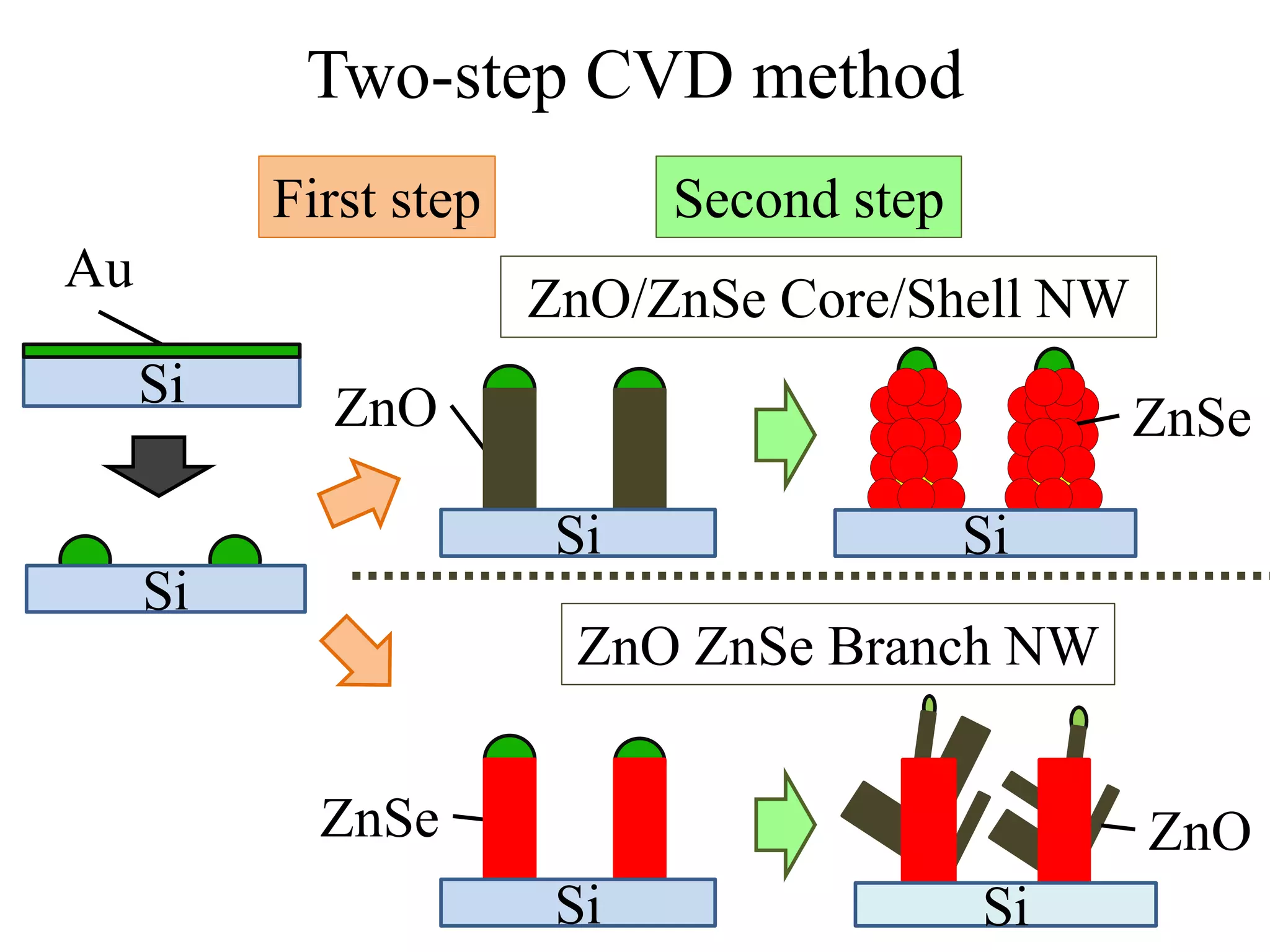

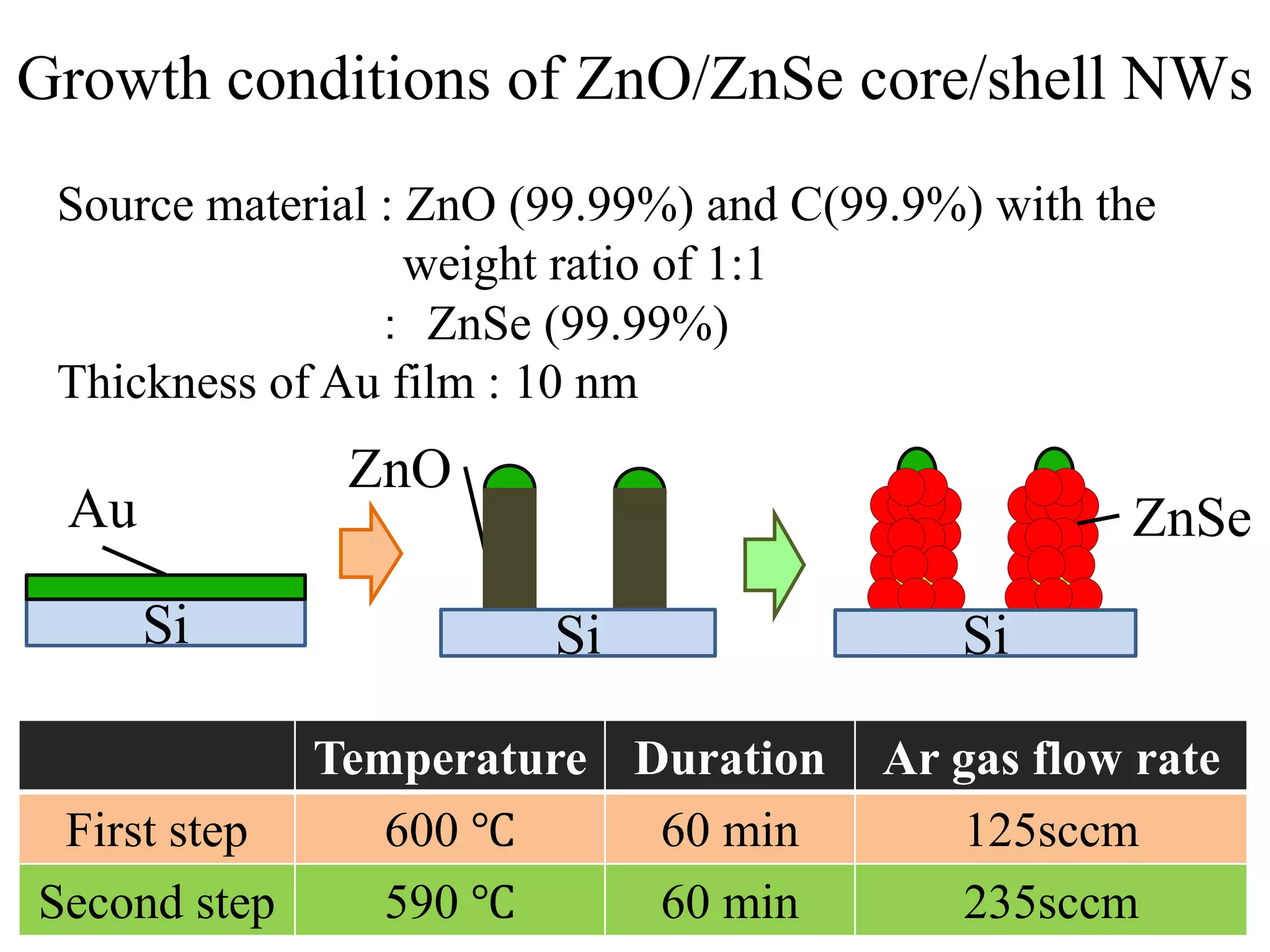

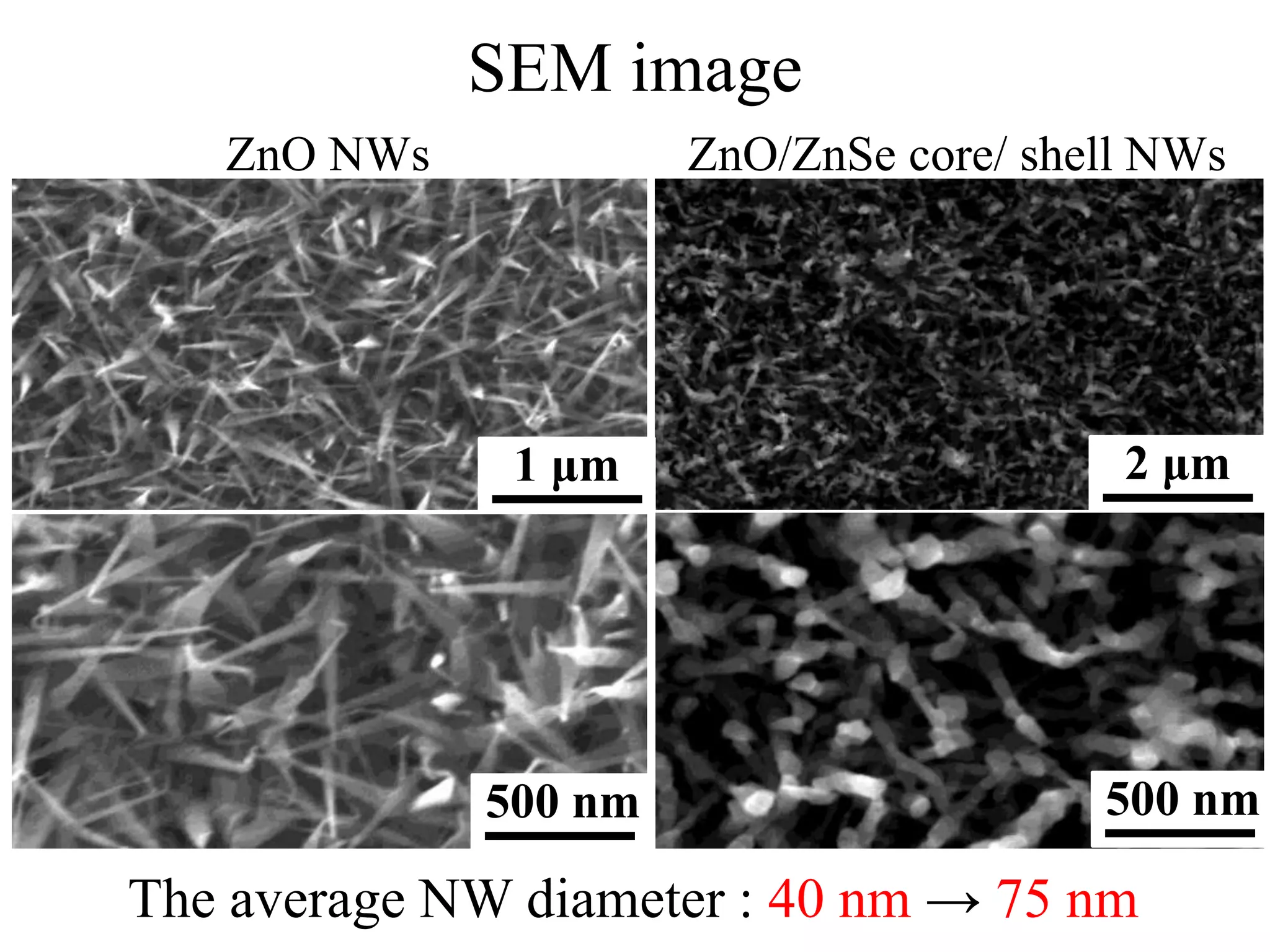

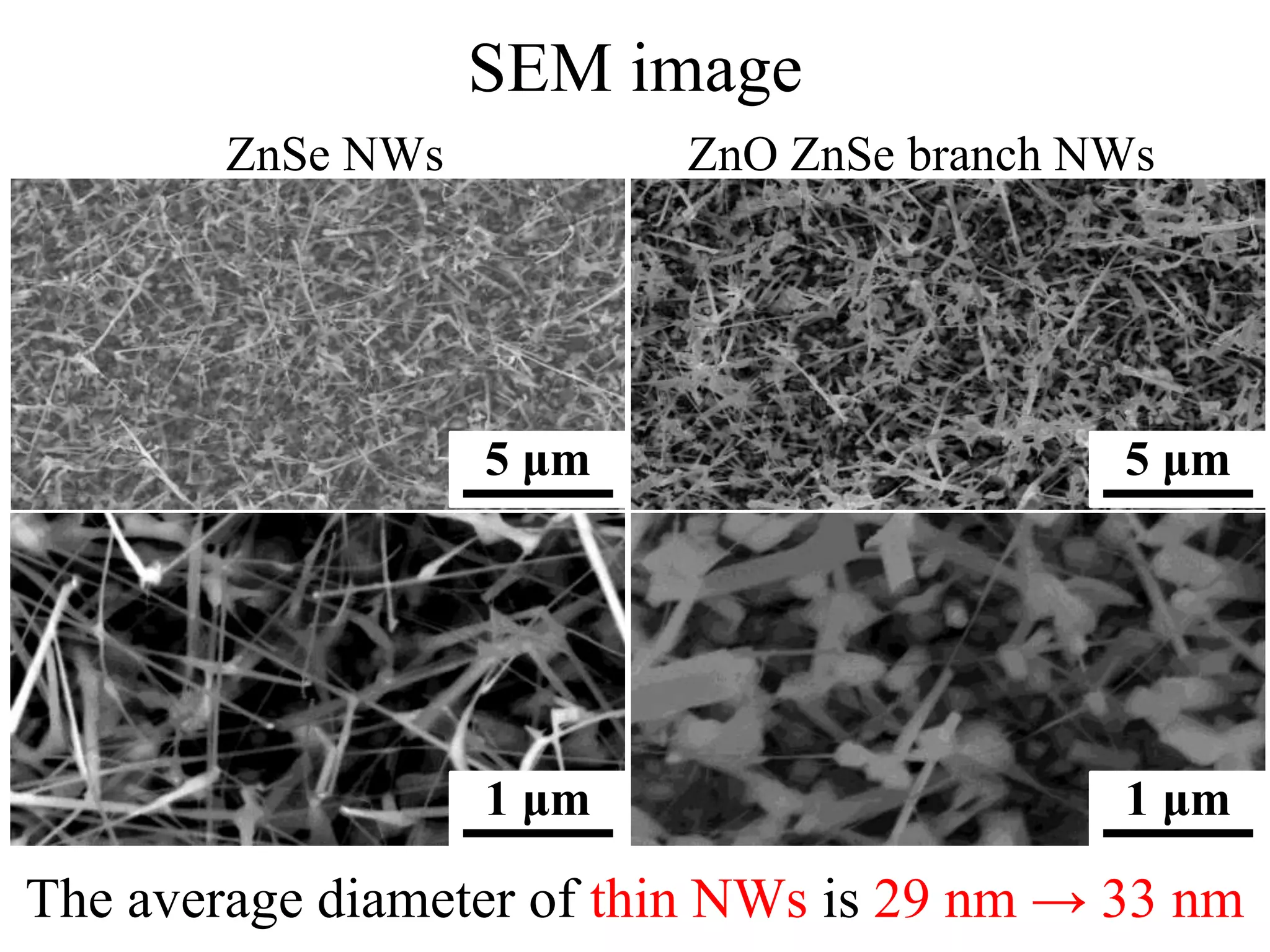

The document discusses the growth and characterization of ZnO/ZnSe nanowires using a two-step chemical vapor deposition method, specifically focusing on their structural and optical properties. It details the growth conditions, average diameters, and photoluminescence emissions of the core/shell structures and branch nanowires. Future work includes electrical property measurements and the fabrication of single nanowire devices, as well as acknowledgments to contributors in the research process.

![Chemical Vapor Deposition (CVD) method

Quartz tube heater

Au on Si substrate ZnO/C or ZnSe

Ar Gas inletAr Gas outlet

0

200

400

600

800

1000

1200

0 10 20 30 40 50 60

Temperature[℃]

Position [cm]](https://image.slidesharecdn.com/conclusionoftheexperimentincanada-161027023536/75/Conclusion-of-the-experiment-in-canada-3-2048.jpg)

![EDX spectrum

The diameter correspond to ZnO/ZnSe core/shell NW

0

50

100

150

200

250

300

0 20 40 60 80 100 120 140 160 180 200

Intensity[a.u.]

Distance [nm]

1 μm

90 nm

120 nm](https://image.slidesharecdn.com/conclusionoftheexperimentincanada-161027023536/75/Conclusion-of-the-experiment-in-canada-7-2048.jpg)

![0

100

200

300

400

0 50 100 150 200 250 300

Intensity[a.u.]

Distance [nm]

0

50

100

150

200

0 30 60 90 120 150 180

Intensity[a.u.] Distance [nm]

ZnO ZnSe branch NW data by EDX line profile

2

1 1

2

1 μm](https://image.slidesharecdn.com/conclusionoftheexperimentincanada-161027023536/75/Conclusion-of-the-experiment-in-canada-11-2048.jpg)