This document presents the final report for the development of a computer integrated heat exchanger test apparatus for a university's thermodynamics laboratory. The report describes the design and fabrication of the apparatus, which allows users to test different types of heat exchangers and vary parameters like temperature, flow rate, and exchanger type. It also outlines the controls and software used, including Arduino and LabVIEW, and presents preliminary testing results. The apparatus aims to provide a low-cost option for analyzing heat exchanger performance compared to commercial units.

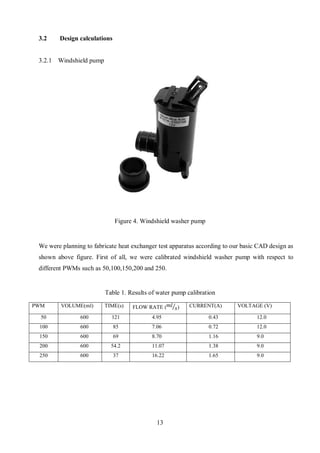

![4

LITERATURE REVIEW

Heat exchanger is a device, such as an automobile radiator, used to transfer heat from a fluid on one

side of a barrier to a fluid on the other side without bringing the fluid into direct contact. Usually,

this barrier is made from metal which has good thermal conductivity in order to transfer heat

effectively from one fluid to another fluid. Besides that, heat exchanger can be defined as any of

several devices that transfer heat from a hot to a cold fluid. In engineering practical, generally, the

hot fluid is needed to cool by the cold fluid. For example, the hot vapor is needed to be cool by

water in condenser practical. Moreover, heat exchanger is defined as a device used to exchange heat

from one medium to another often through metal walls, usually to extract heat from a medium

flowing between two surfaces. In automotive practice, radiator is used as heat exchanger to cool

hot water from engine by air surrounding same like intercooler which used as heat exchanger to

cool hot air for engine intake manifold by Air surrounding. Usually, this device is made from

aluminum since it is lightweight and good thermal conductivity.

2.1 Function of heat exchanger

Heat exchanger is a special equipment type because when heat exchanger is directly fired by a

combustion process, it becomes furnace, boiler, heater, tube-still heater and engine. Vice versa,

when heat exchanger makes a change in phase in one of flowing fluid such as condensation of steam

to water, it becomes a chiller, evaporator, sublimate, distillation-column reboiler, still, condenser

or cooler-condenser. Heat exchanger may be designed for chemical reactions or energy-generation

processes which become an integral part of reaction system such as a nuclear reactor, catalytic

reactor or polymer. Normally, heat exchanger is used only for the transfer and useful elimination or

recovery of heat without changed in phase. The fluids on either side of the barrier usually liquids

but they can be gasses such as steam, air and hydrocarbon vapor or can be liquid metals such as

sodium or mercury. In some application, heat exchanger fluids may use fused salts [2].](https://image.slidesharecdn.com/0a9daa0f-0668-43a8-8d6b-c28c9dd5a723-170105180109/85/COMPUTER-INTERGRATED-HEAT-EXCHANGER-LABORATORY-APPARATUS-10-320.jpg)

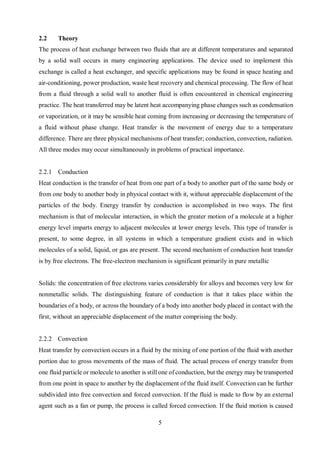

![31

Partial cells 8504

Irregular cells 0

Trimmed cells 0

Min/Max Table

Name Minimum Maximum

Density (Fluid)

[kg/m^3]

987.52 987.52

Density (Solid)

[kg/m^3]

17170.00 17170.00

Pressure [Pa] 101318.14 101981.74

Temperature [K] 304.00 323.00

Temperature (Fluid)

[K]

304.00 323.00

Temperature (Solid)

[K]

323.00 323.00

Velocity [m/s] 0 2.311

Velocity (X) [m/s] -2.311 8.985e-024

Velocity (Y) [m/s] -0.005 0.005

Velocity (Z) [m/s] -0.008 0.009

Velocity RRF [m/s] 0 2.311

Velocity RRF (X)

[m/s]

-2.311 8.985e-024

Velocity RRF (Y)

[m/s]

-0.005 0.005

Velocity RRF (Z)

[m/s]

-0.008 0.009

Vorticity [1/s] 1.62e-023 1503.49

Relative Pressure [Pa] -6.86 656.74

Shear Stress [Pa] 2.90e-026 16.65

Bottleneck Number [ ] 2.0700438e-017 1.0000000

Heat Flux [W/m^2] 1.576e-004 0.911](https://image.slidesharecdn.com/0a9daa0f-0668-43a8-8d6b-c28c9dd5a723-170105180109/85/COMPUTER-INTERGRATED-HEAT-EXCHANGER-LABORATORY-APPARATUS-37-320.jpg)

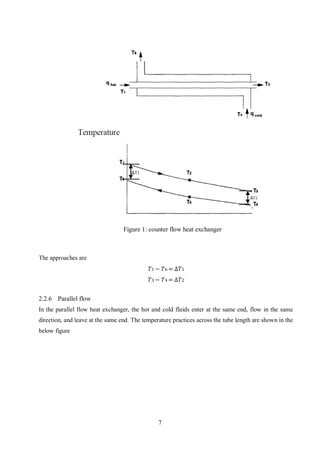

![32

Heat Transfer

Coefficient [W/m^2/K]

1.866e-009 0.028

Overheat above

Melting Temperature [K]

-1030.150 -1030.150

ShortCut Number [ ] 7.9225902e-031 1.0000000

Surface Heat Flux

[W/m^2]

-0.828 0.358

Engineering Database

Solids

Copper Tungsten (Cu10/W90)

Path: Solids Pre-DefinedAlloys

Density: 17170.00 kg/m^3

Specific heat: 149.2 J/(kg*K)

Conductivity type: Isotropic

Thermal conductivity: 160.0000 W/(m*K)

Electrical conductivity: Conductor

Resistivity: 6.4000e-008 Ohm*m

Radiation properties: No

Melting temperature: Yes

Temperature: 1353.15 K

Liquids

Water

Path: Liquids Pre-Defined](https://image.slidesharecdn.com/0a9daa0f-0668-43a8-8d6b-c28c9dd5a723-170105180109/85/COMPUTER-INTERGRATED-HEAT-EXCHANGER-LABORATORY-APPARATUS-38-320.jpg)

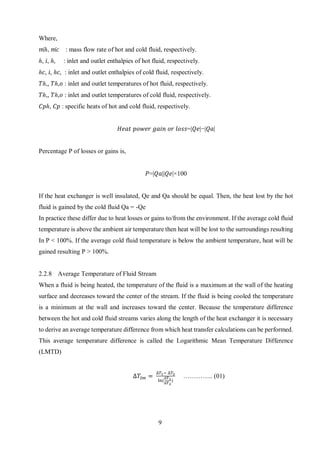

![33

Density

Dynamic viscosity

Specific heat (Cp)

Thermal conductivity

0

200

400

600

800

1000

1200

0 100 200 300 400 500 600

Density[kg/m^3]

Temperature[K]

0

0.0005

0.001

0.0015

0.002

0 100 200 300 400 500 600

Dynamicviscosity[Pa*s]

Temperature[K]

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0 100 200 300 400 500 600

Thermalconductivity[W/(m*K)]

Temperature[K]

4100

4200

4300

4400

4500

4600

4700

4800

4900

0 100 200 300 400 500 600

Specificheat(Cp)[J/(kg*K)]

Temperature[K]](https://image.slidesharecdn.com/0a9daa0f-0668-43a8-8d6b-c28c9dd5a723-170105180109/85/COMPUTER-INTERGRATED-HEAT-EXCHANGER-LABORATORY-APPARATUS-39-320.jpg)

![37

BIBLIOGRAPHY

[1] A. Ltd, “Computer Controlled Heat Exchanger Service Module,” Armfield Ltd, 2016.

[Online]. Available: http://discoverarmfield.com/en/products/view/ht30xc/computer-

controlled-heat-exchanger-service-module. (May 2016)

[2] M. S. BIN ALIAS, “DESIGN OF SMALL HEAT EXCHANGER,” 2010.

[3] D. P. F. P. I. A. S. L. DeWitt, willey, 7th ed. wiley, 2011.](https://image.slidesharecdn.com/0a9daa0f-0668-43a8-8d6b-c28c9dd5a723-170105180109/85/COMPUTER-INTERGRATED-HEAT-EXCHANGER-LABORATORY-APPARATUS-43-320.jpg)

![38

APPENDIX

DEPARTMENT OF MECHANICAL AND MANUFACTURING ENGINEERING

M3 – THERMODYNAMIC LABORATORY

MEXXXX: HEAT TRANSFER

Lab sheet

DATE :

TITLE : OVERALL HEAT TRANSFER COEFFICIENT

AIM :

NOTATIONS:

Symbol

To evaluate the performance of a Heat Exchanger in

counter flow under variations of flow rates

Description Units

U Overall heat transfer coefficient [kW/𝑚2

K]

A Hot water tube surface area [𝑚2

]

𝑚̇ ℎ Mass flow rate of hot water [kg/s]

𝐶ℎ Specific heat of hot water [J/kg K]

𝑇1 Cold water inlet Temperature [K]

𝑇2 Cold water outlet Temperature [K]

𝑇3 Hot water inlet Temperature [K]

𝑇4 Hot water outlet Temperature [K]

𝑇5 Hot water reservoir tank Temp. [K]

∆𝑇1 , ∆𝑇2 Temperature difference [K]

𝑄ℎ Heat emitted by cold water [K]

∆𝑇𝑙𝑚 LMTD value [K]

THEORY:

Applying the First Law of Thermodynamics, to the hot water side,

𝑄ℎ = 𝑚̇ ℎ (𝑇3 − 𝑇4)](https://image.slidesharecdn.com/0a9daa0f-0668-43a8-8d6b-c28c9dd5a723-170105180109/85/COMPUTER-INTERGRATED-HEAT-EXCHANGER-LABORATORY-APPARATUS-44-320.jpg)

![40

DATA:

Diameter of copper tube = 0.01m

Length of copper tube = 0.50m

CALCULATIONS:

Find the overall heat transfer coefficient for Copper and Water.

RESULTS:

Write the results you obtained.

DISCUSSION:

Write a discussion describing the following points.

1. Practical importance of the experiment.

2. State the assumptions you made during the practical.

3. Point out the problems associated with the practical.

4. Mention the reasons for the deviation of the values you obtained from the theoretical values.

REFERENCE:

[1] “Experiment Lab Manual.” [Online]. Available:

https://web.njit.edu/~me/ME_406_Exp6_Lab_Manual.pdf. [Accessed: 19-Nov-2016].](https://image.slidesharecdn.com/0a9daa0f-0668-43a8-8d6b-c28c9dd5a723-170105180109/85/COMPUTER-INTERGRATED-HEAT-EXCHANGER-LABORATORY-APPARATUS-46-320.jpg)