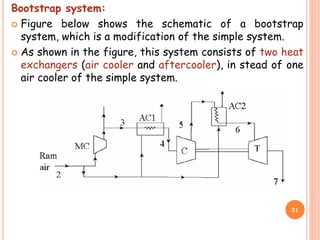

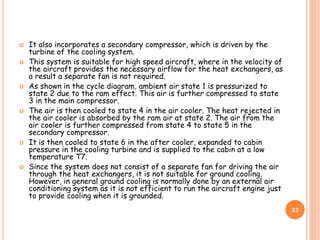

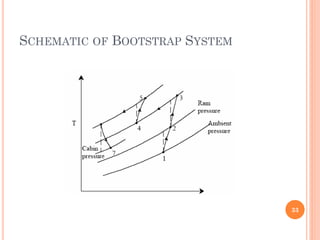

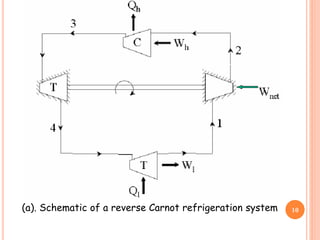

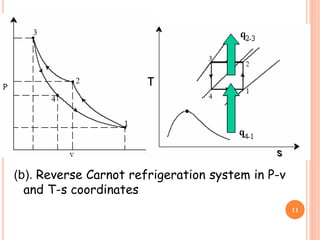

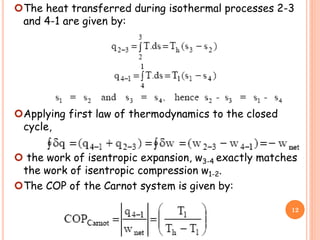

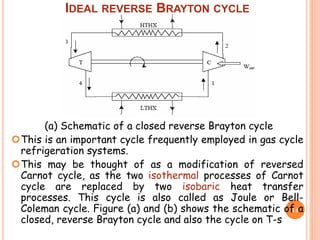

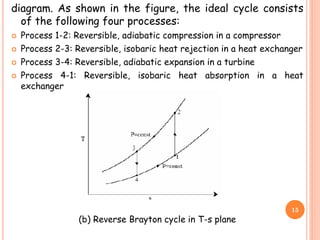

This document discusses air cycle refrigeration systems used in aircraft cabin cooling. It begins by introducing air cycle refrigeration and its advantages for aircraft applications. It then describes the ideal reverse Brayton cycle and compares it to the Carnot cycle. Key concepts of compression, expansion, and heat transfer processes are explained. Actual cycle analysis accounts for irreversibilities. Common aircraft refrigeration cycles are introduced, including the simple cycle and bootstrap system. The bootstrap system improves on the simple cycle by using a secondary compressor to boost efficiency during high-speed flight when ram air is available.

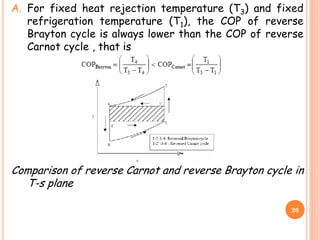

![B. COP of Brayton cycle approaches COP of Carnot cycle

as T1 approaches T4 (thin cycle), however, the specific

refrigeration effect [cp(T1-T4)] also reduces

simultaneously.

C. COP of reverse Brayton cycle decreases as the

pressure ratio rp increases

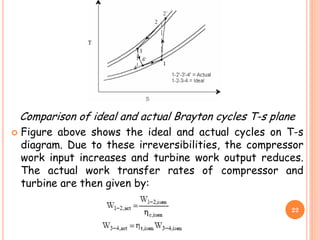

Actual reverse Brayton cycle:

The actual reverse Brayton cycle differs from the ideal

cycle due to:

I. Non-isentropic compression and expansion processes

II. Pressure drops in cold and hot heat exchangers

21](https://image.slidesharecdn.com/air-cyclerefrigeration-230305105401-e8d0d2df/85/Air-Cycle-refrigeration-pdf-21-320.jpg)