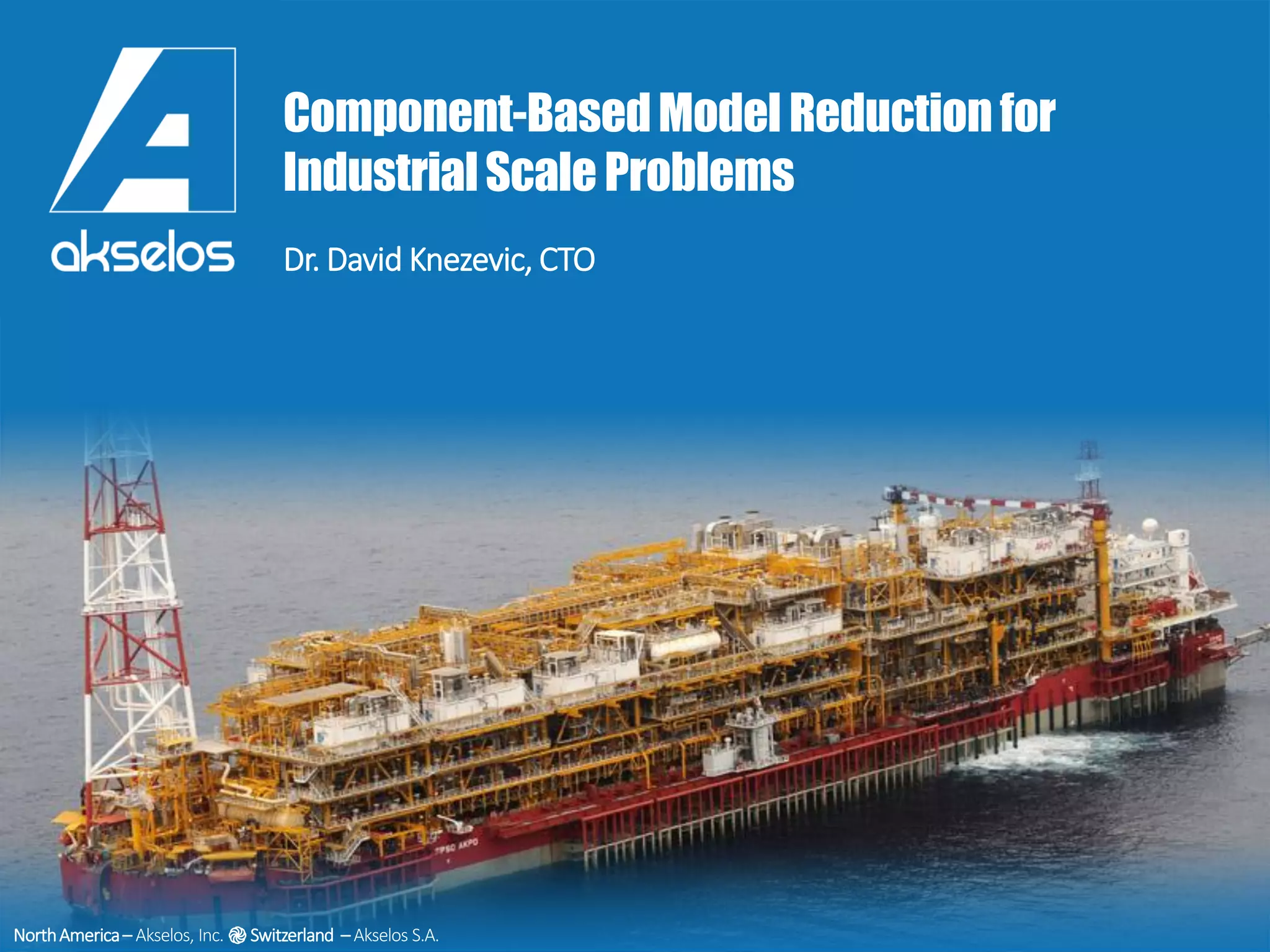

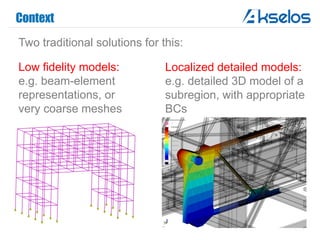

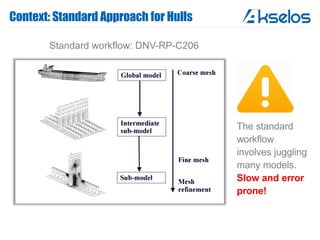

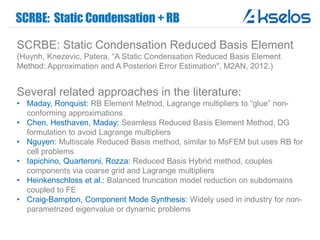

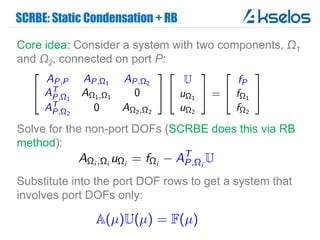

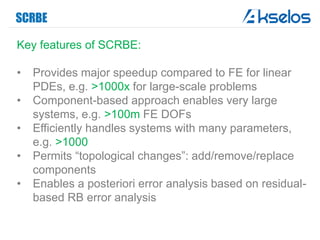

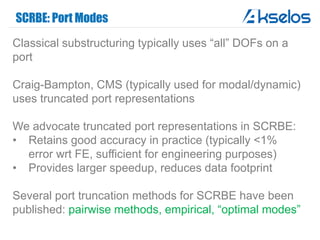

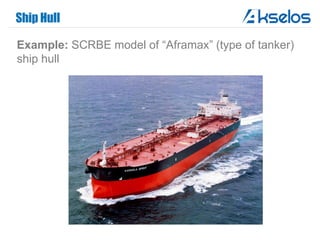

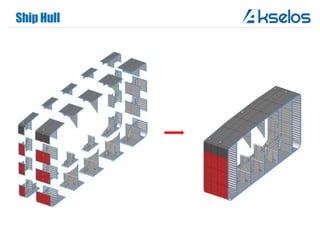

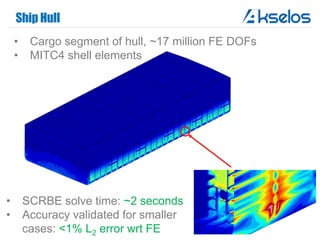

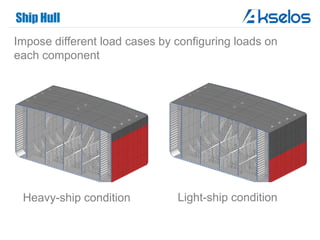

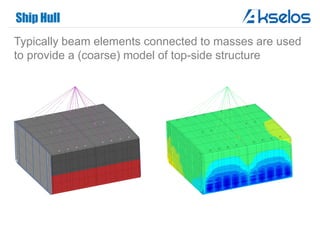

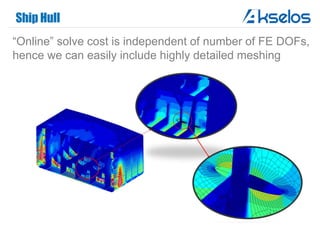

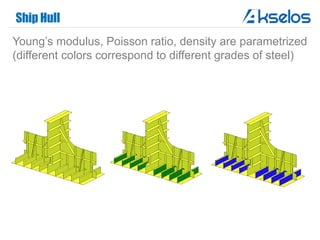

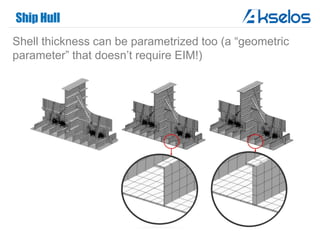

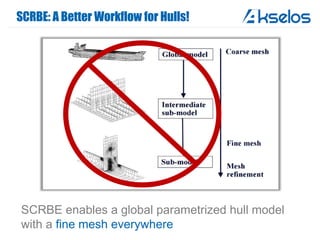

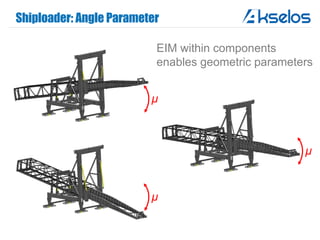

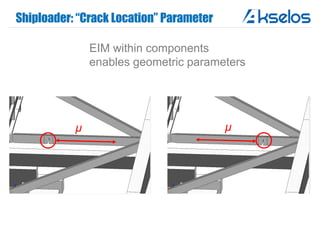

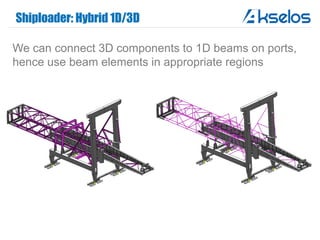

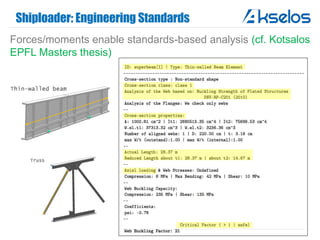

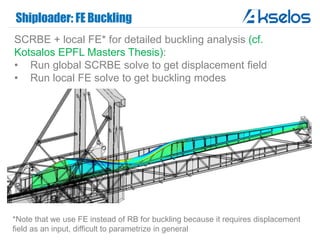

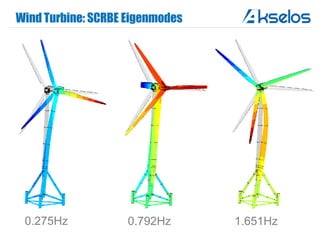

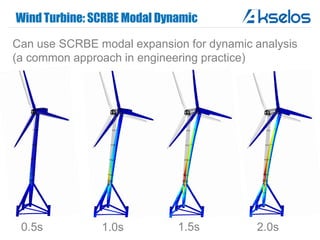

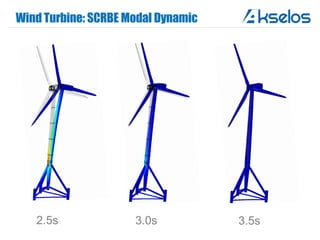

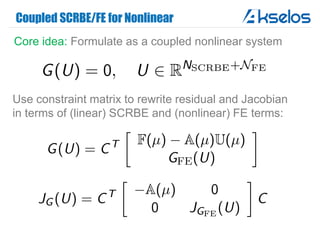

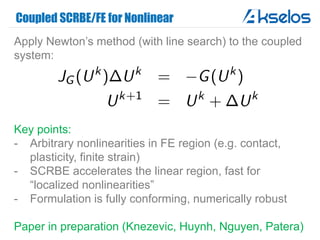

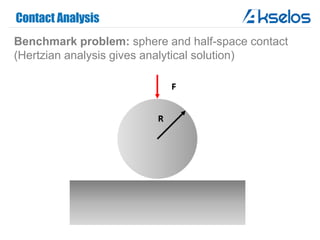

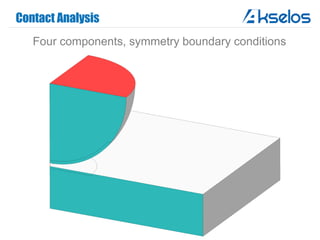

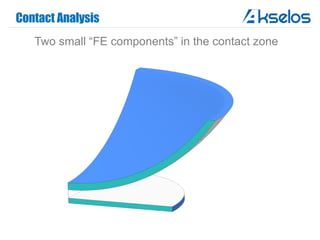

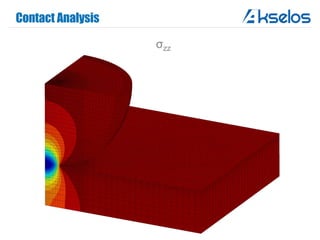

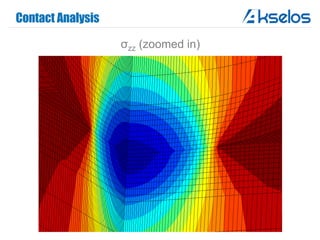

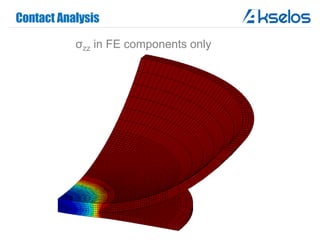

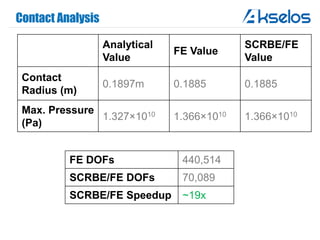

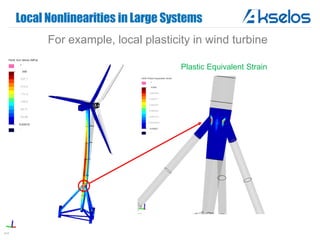

Akselos, Inc. presents a component-based model reduction approach (SCRBE) to efficiently simulate large and complex systems such as ships and wind turbines. SCRBE offers significant speedups for linear PDEs, enables the analysis of over 100 million finite elements, and supports nonlinear analysis through a coupled SCRBE/FE solver. An example case demonstrated how SCRBE improved the modeling of an Aframax ship hull, achieving solve times of under 2 seconds while maintaining accuracy.