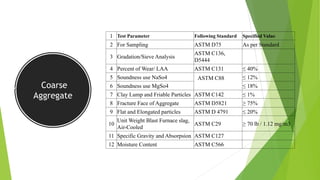

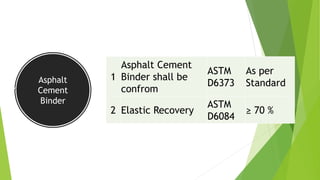

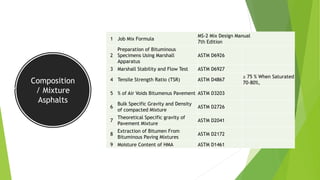

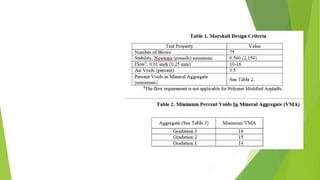

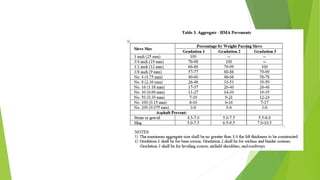

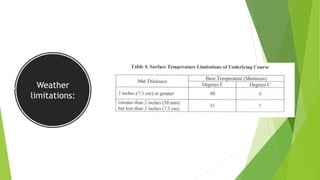

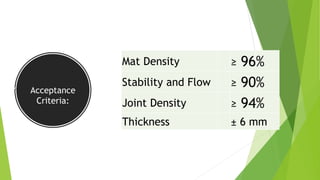

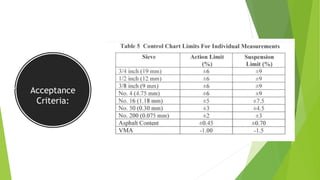

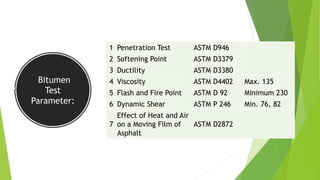

This document outlines test requirements for asphalt work including specifications for aggregate, fine aggregate, mineral filler, asphalt cement binder, composition and mixture testing. Requirements are defined for sampling, gradation, impurities and other properties using standards like ASTM. Acceptance criteria include minimum density, stability and thickness tolerances. Key tests are specified for bitumen properties like penetration, softening point, viscosity and flash/fire points.