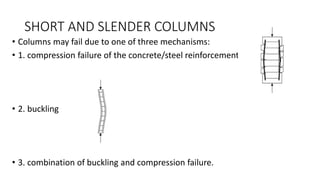

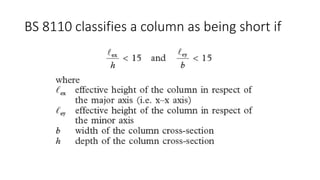

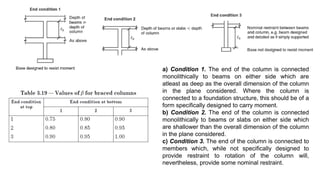

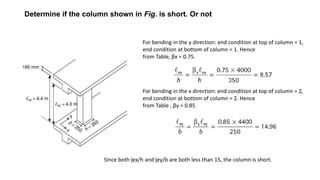

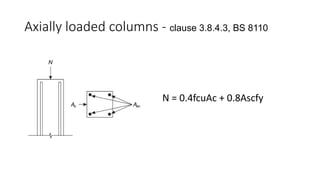

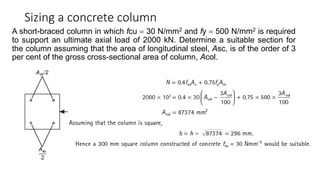

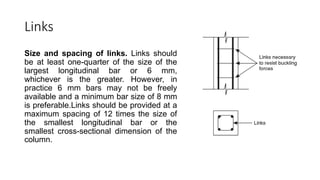

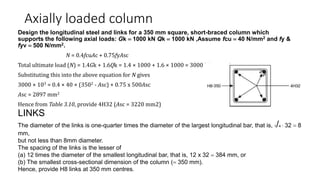

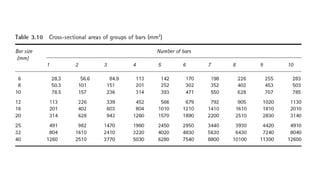

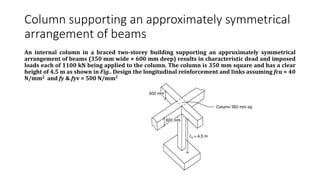

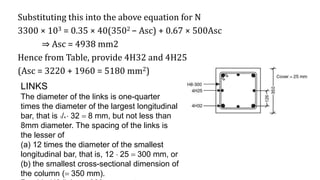

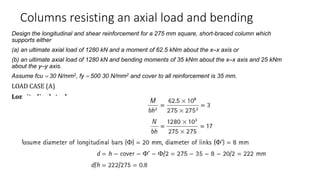

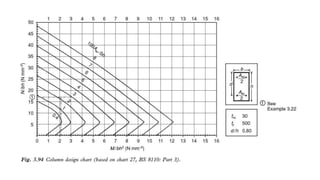

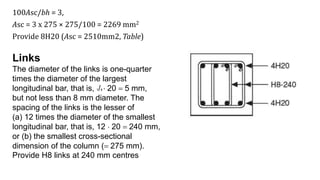

The document discusses the design and classification of short columns in structural engineering, detailing failure mechanisms, reinforcement requirements, and load capacities. It explains how to determine a column's short status based on connections and provides equations for sizing reinforcement in different loading scenarios. Additionally, it outlines specific reinforcement sizes, spacings, and conditions for axial and bending loads in various column configurations.