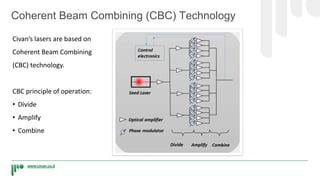

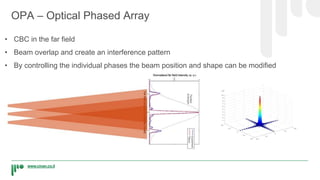

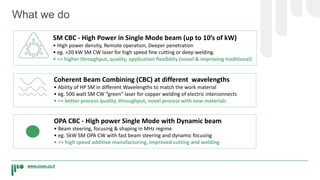

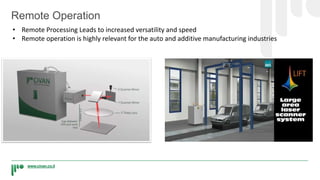

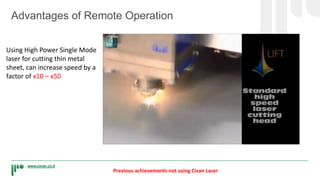

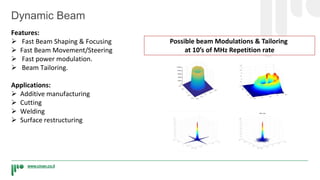

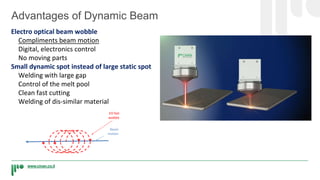

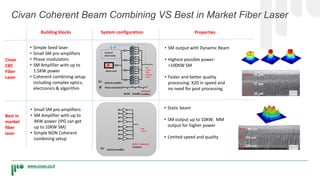

Civan is an Israeli company established in 2008 with 120 employees that develops high power fiber lasers using Coherent Beam Combining (CBC) technology. CBC allows the lasers to achieve powers over 100 kW in single mode beams, enabling processing speeds up to 20 times faster than conventional fiber lasers with better quality. Civan's lasers can also produce dynamic beams through fast beam shaping, focusing and steering for applications like high-speed additive manufacturing.