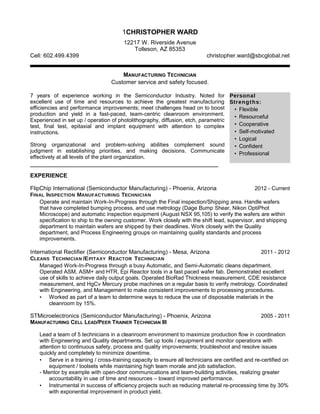

Christopher Ward has over 7 years of experience in the semiconductor industry as a manufacturing technician. He has a track record of improving efficiencies and meeting production goals through strong problem-solving, organization, and communication skills. His resume highlights experiences operating various semiconductor manufacturing equipment and leading a team as cell lead to maximize production flow. He has achieved notable results such as reducing material reprocessing time by 30% and slashing customer returns in half.