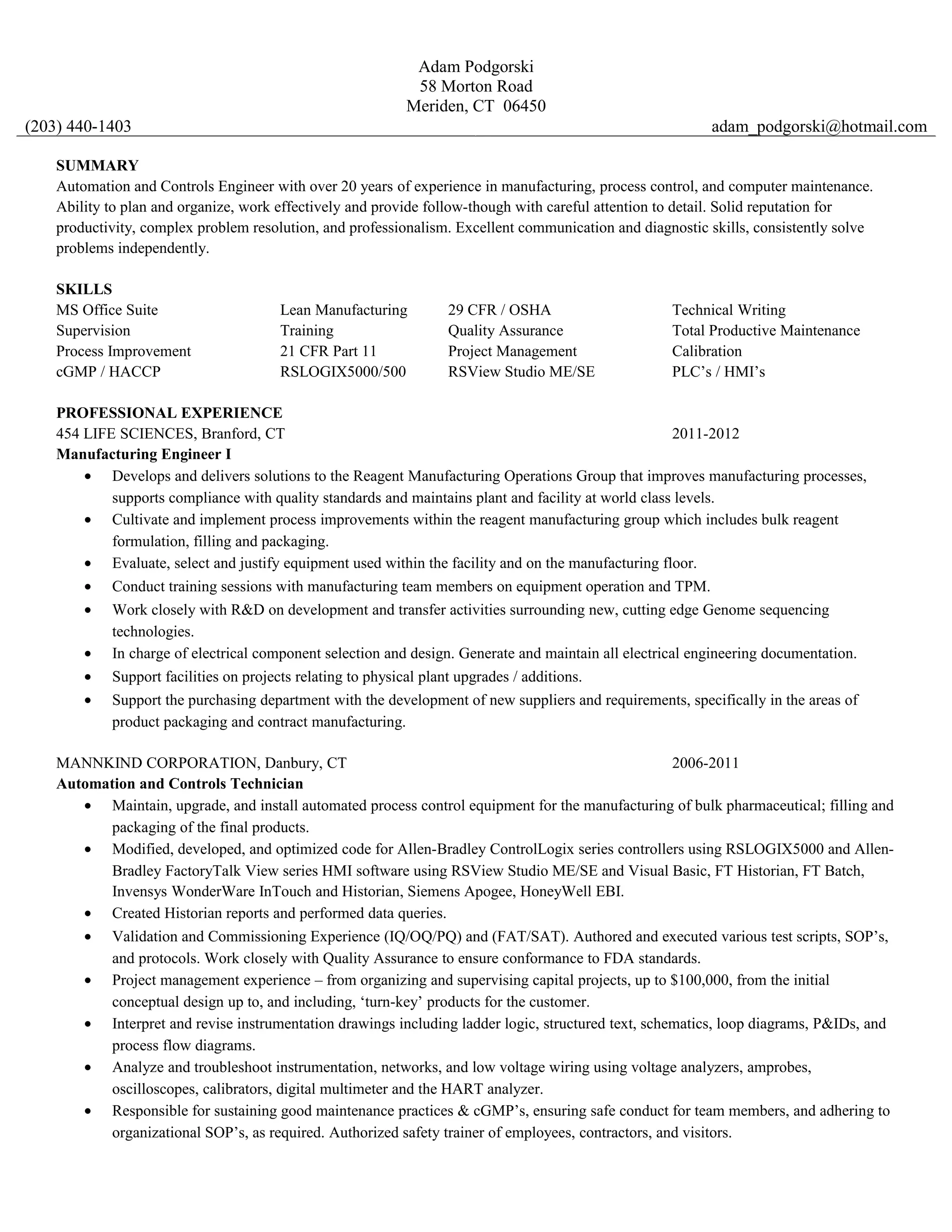

The document is a resume for Adam Podgorski, an automation and controls engineer with over 20 years of experience in manufacturing, process control, and computer maintenance. He has skills in areas such as Lean Manufacturing, quality assurance, and PLC/HMI systems. His professional experience includes roles at 454 Life Sciences, MannKind Corporation, Beiersdorf Inc., Van Dyk Baler Corp., and Quality Mounting and Laminating Systems, as well as serving in the US Air Force. He holds a Master's degree in Technology Management and a Bachelor's degree in Electro-Mechanical Technology.