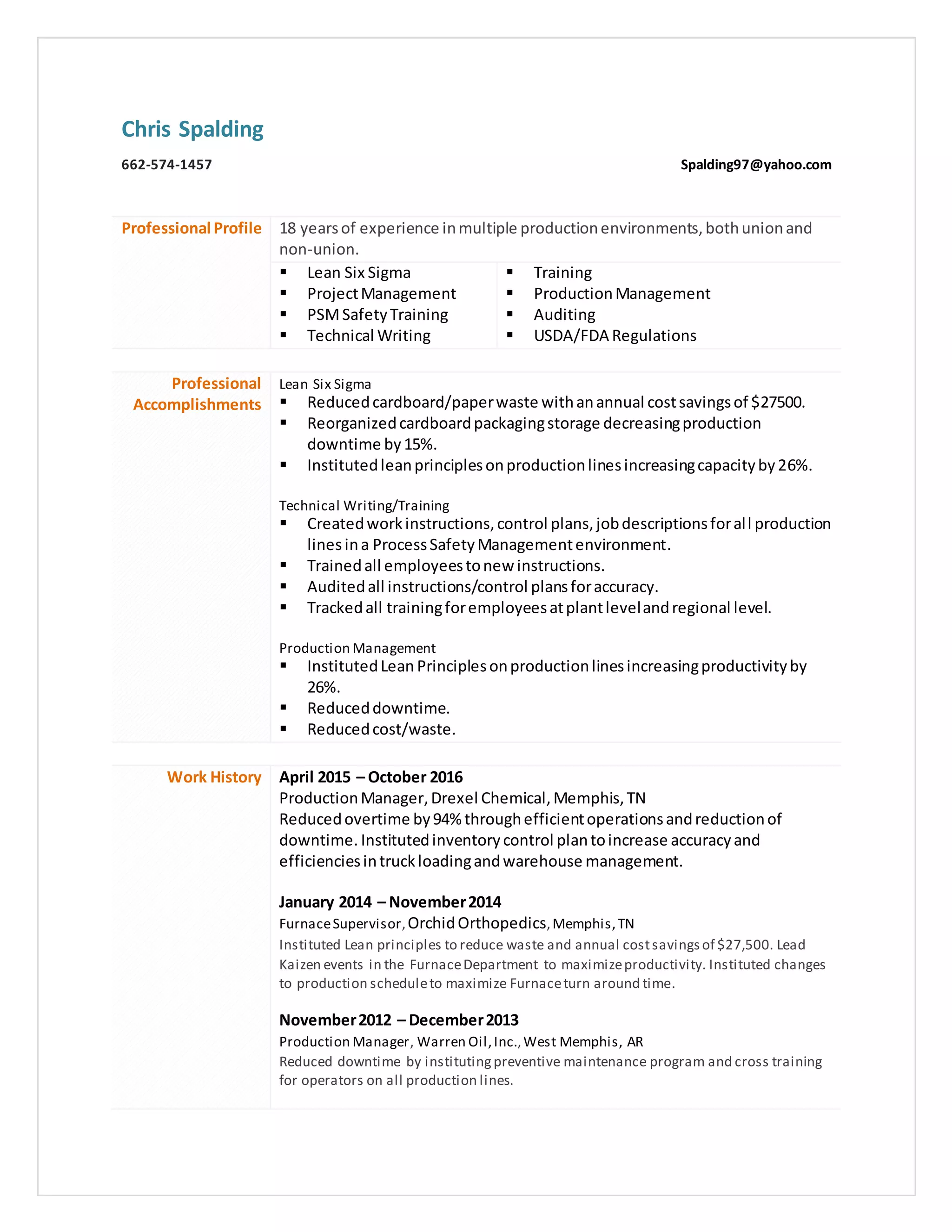

This document provides a summary of Chris Spalding's professional profile, accomplishments, and work history. It highlights 18 years of experience in union and non-union production environments, including expertise in Lean Six Sigma, project management, safety training, technical writing, training, production management, auditing, and FDA/USDA regulations. Specific accomplishments include reducing waste and costs through Lean Six Sigma projects and technical writing/training responsibilities. The work history section outlines roles as a Production Manager and Supervisor with accomplishments like instituting Lean principles to boost productivity and efficiency.