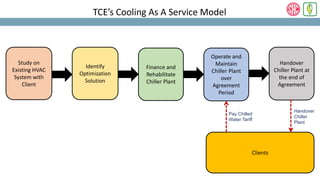

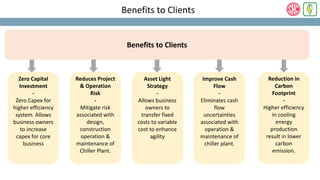

Tunas Cool Energy Sdn Bhd offers a Cooling As A Service model that allows clients to optimize their air conditioning systems without capital investment. Under this model, Tunas Cool Energy will finance and rehabilitate a client's chiller plant to use more efficient cooling technologies. They will then operate and maintain the chiller plant over the agreement period, and clients pay a chilled water tariff. This allows clients to avoid capital expenses for upgrading their chiller plant while reducing operational risks and improving cash flow. It also lowers clients' carbon footprint through increased cooling energy efficiency.