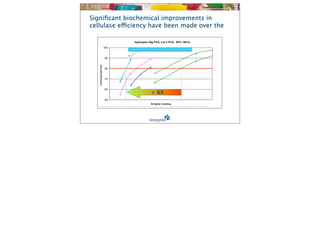

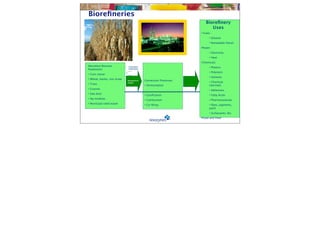

Novozymes is a world leader in industrial biotechnology, producing enzymes and microorganisms. The presentation discusses how enzyme technology provides environmental advantages over conventional processes by working under mild conditions, being renewable and biodegradable. Enzymes can improve product quality, save resources like water and energy, and enable novel products. Novozymes leverages biotechnology expertise to source, improve and produce enzymes at an industrial scale through recombinant techniques, diversity generation and state-of-the-art facilities.