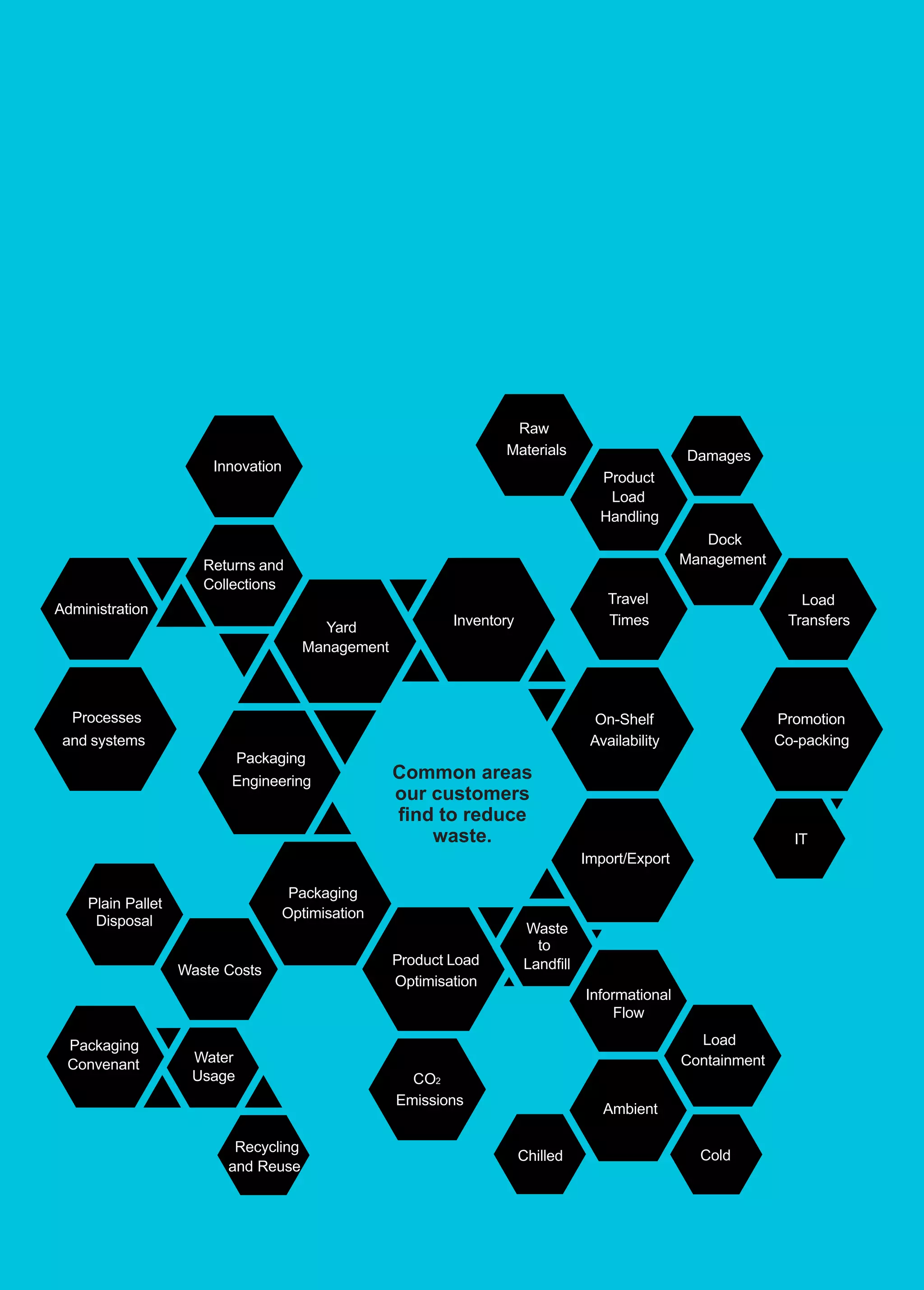

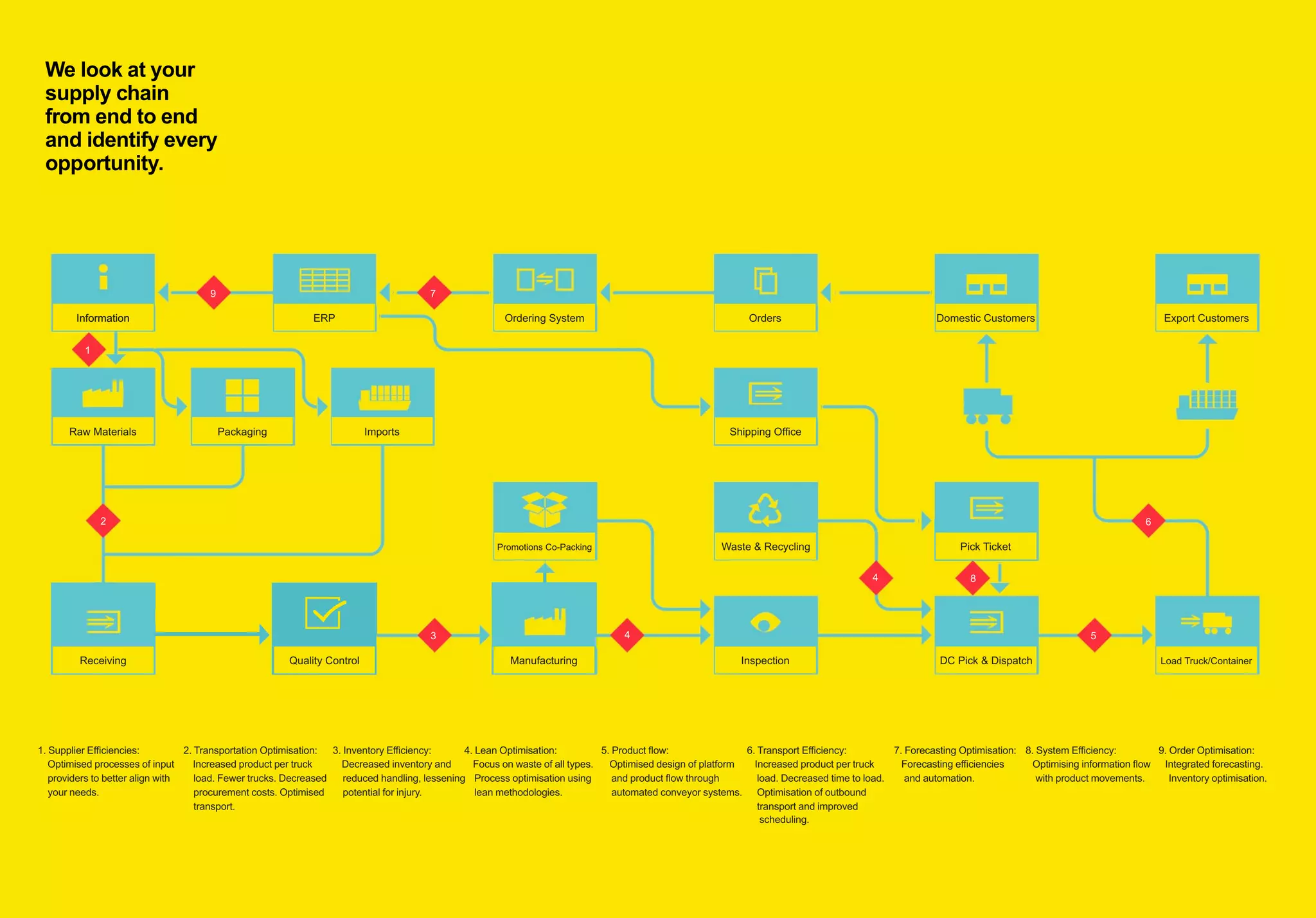

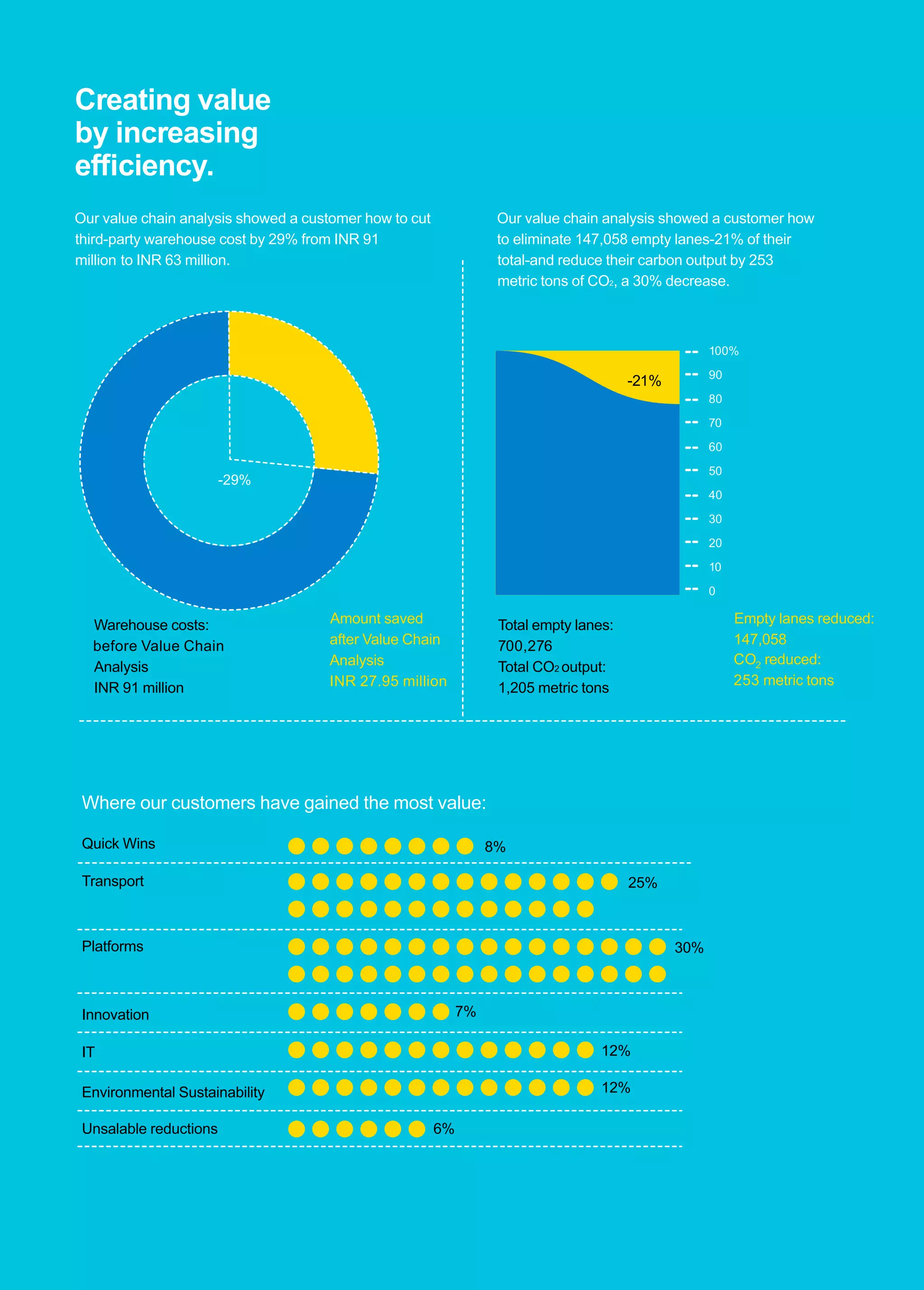

The document discusses value chain analysis as a means to identify and eliminate inefficiencies in supply chains while enhancing operational visibility and sustainability. Through collaborative investigations, it provides a detailed mapping of a company's supply chain, enabling the identification of waste, improvement of efficiencies, and better alignment with best practices. Chep's value chain analysis has led to significant cost savings and environmental benefits for clients, illustrating their expertise in optimizing supply chain processes.