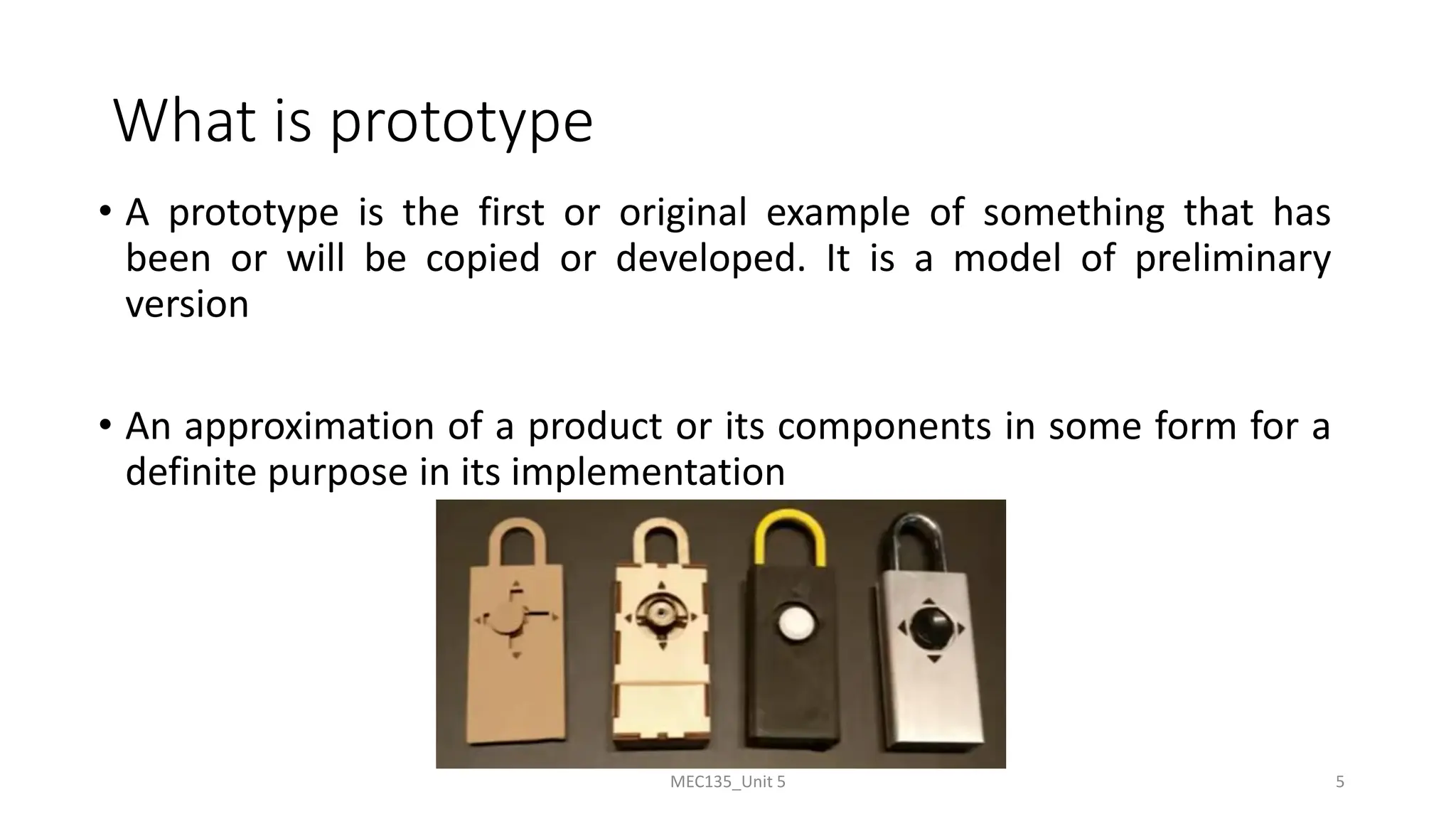

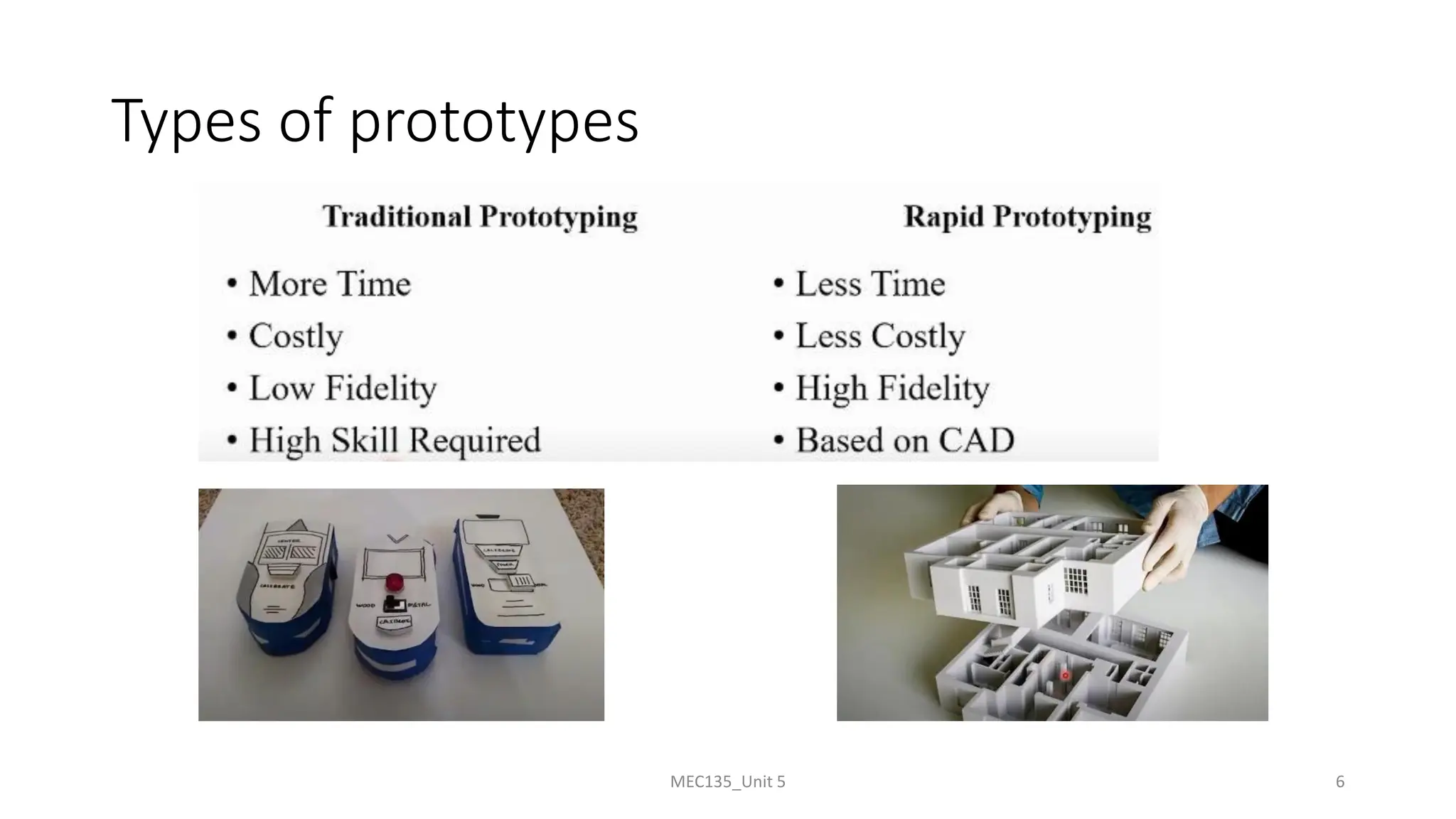

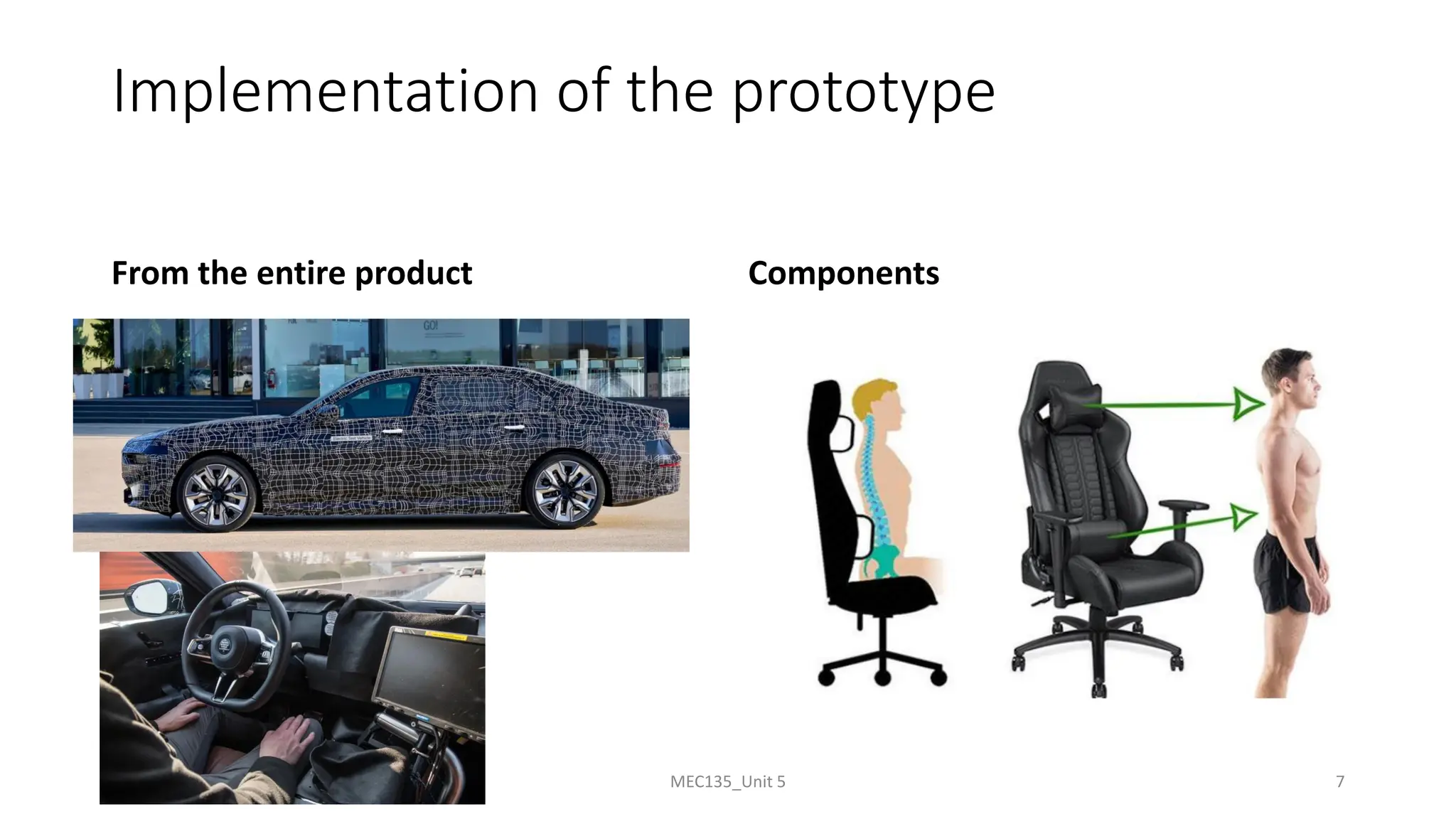

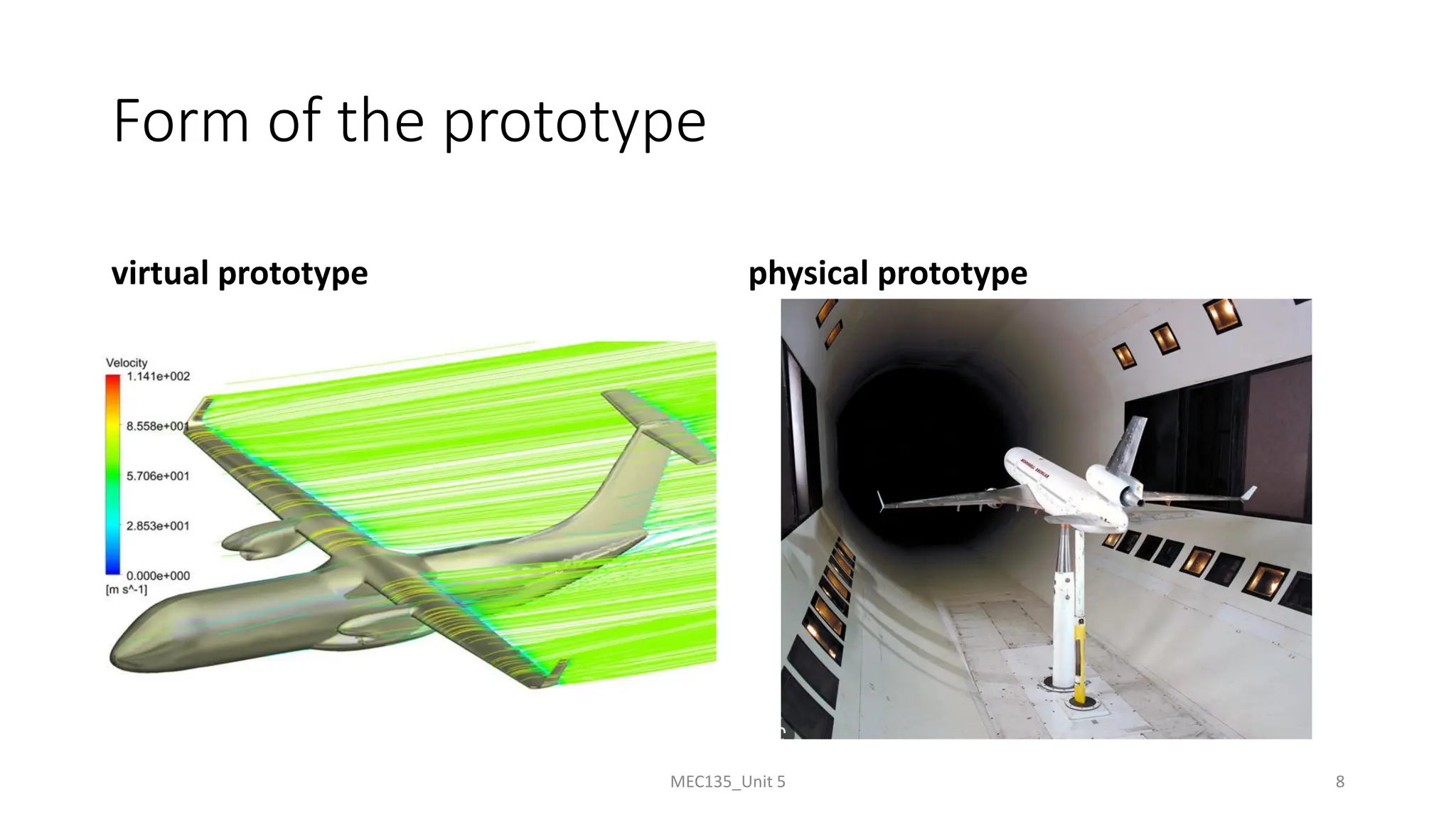

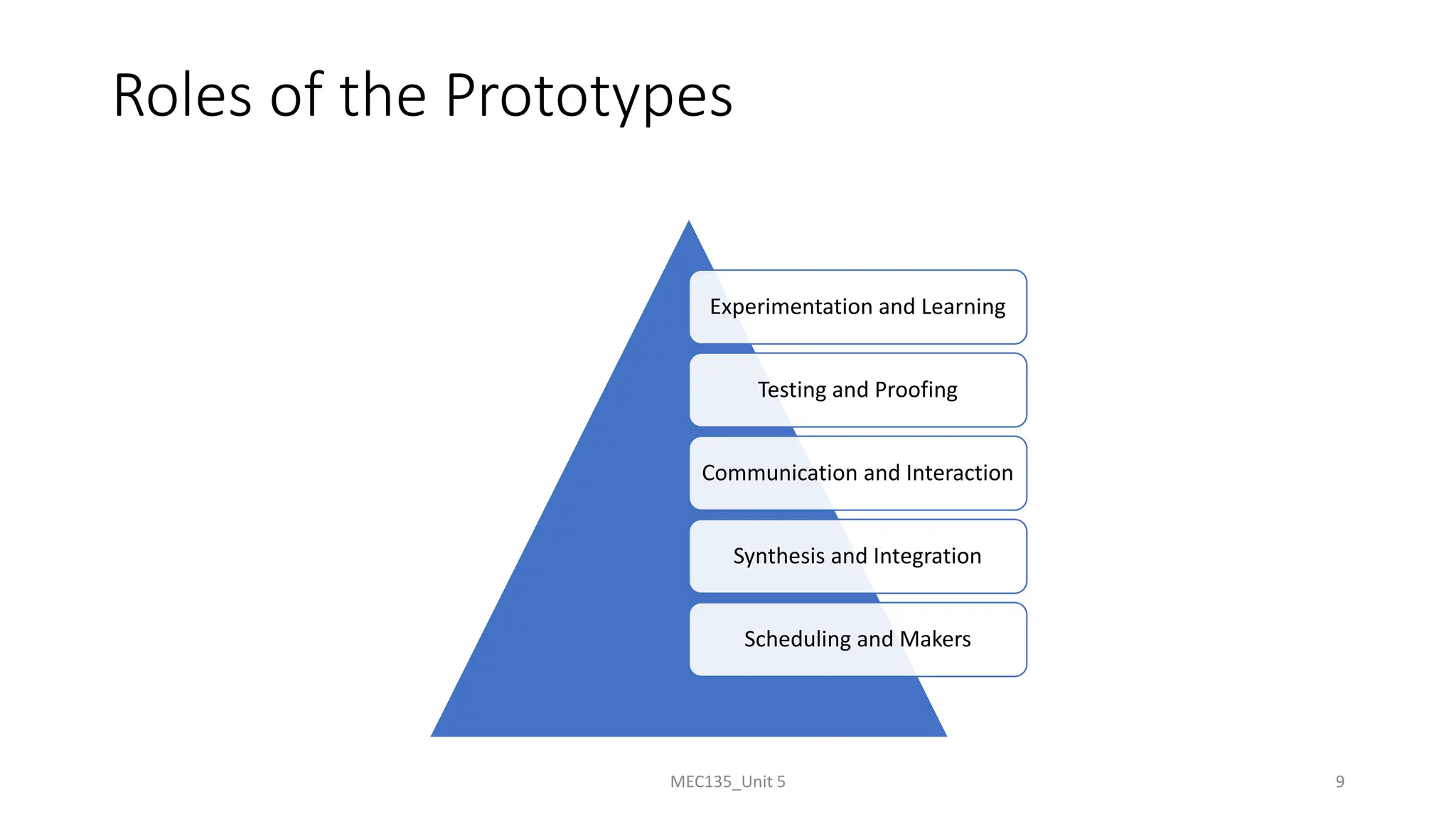

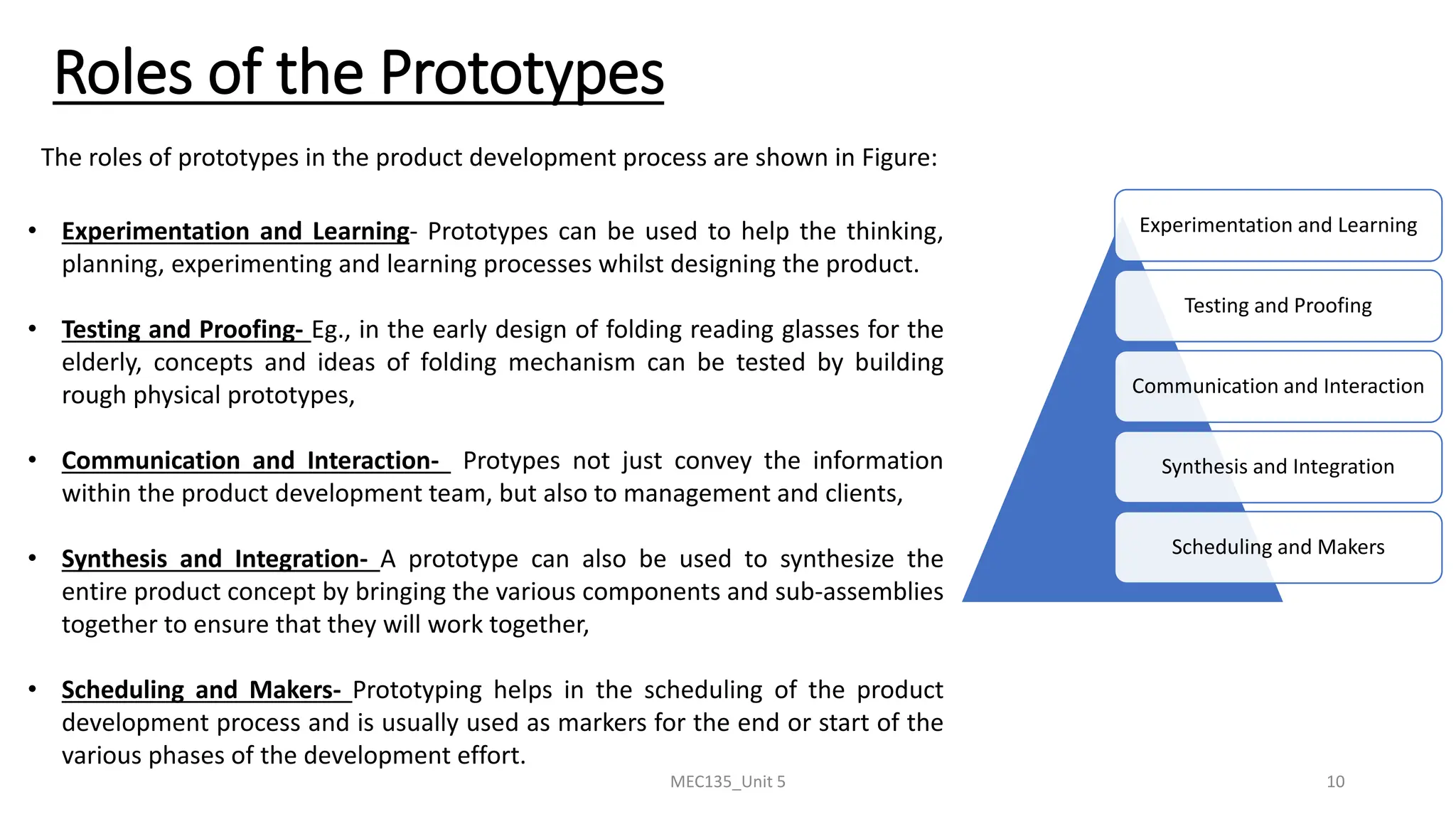

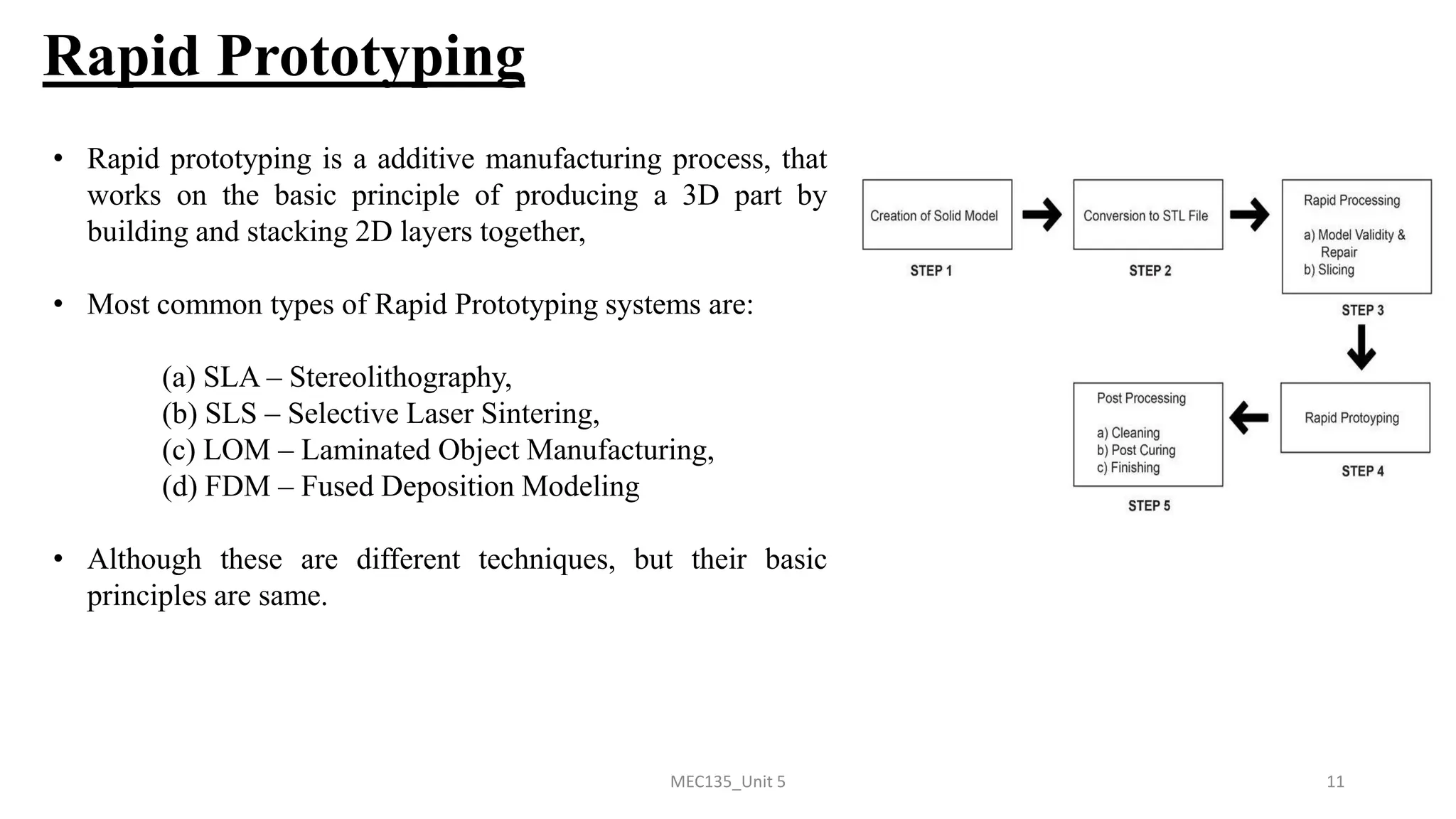

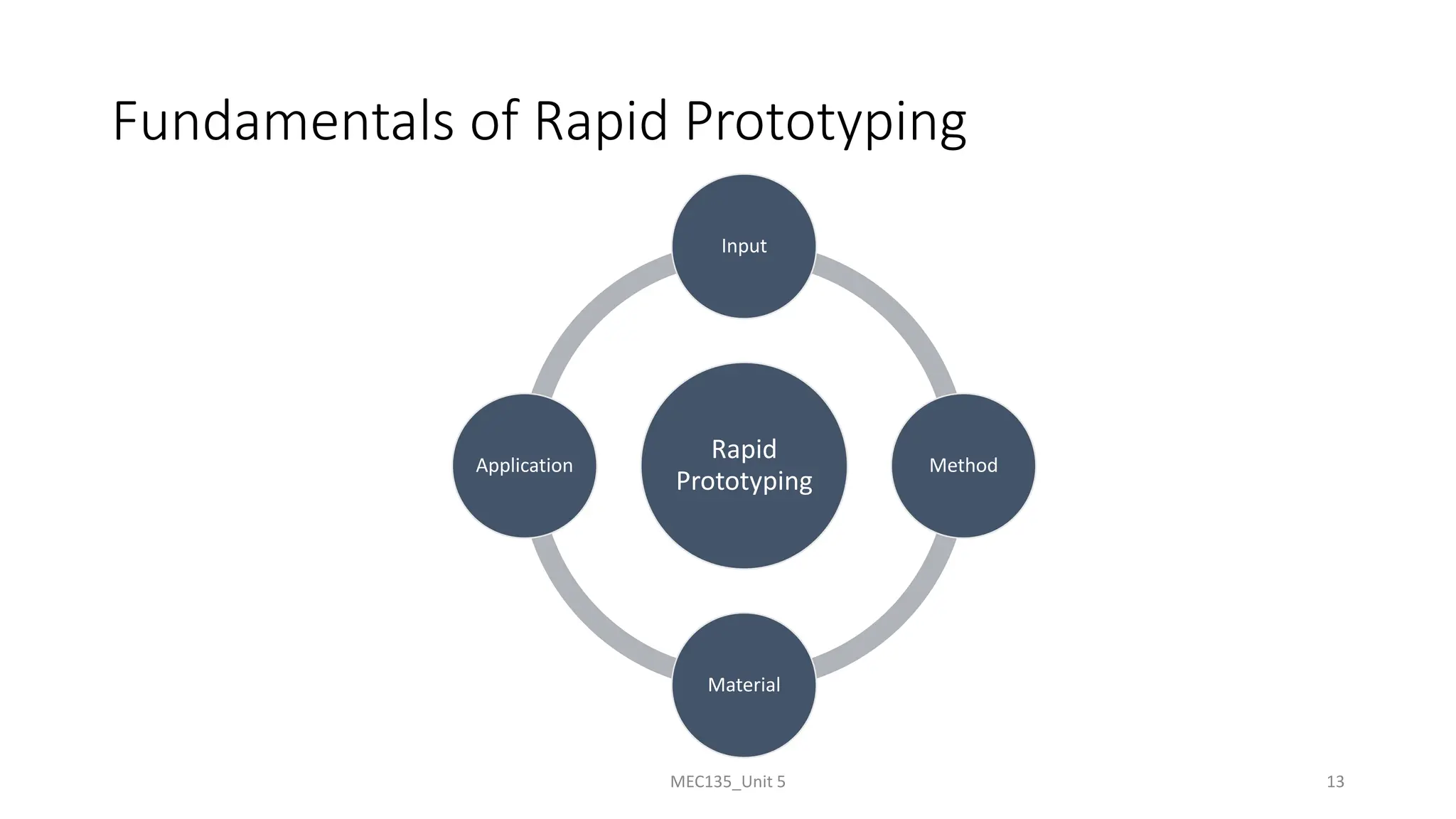

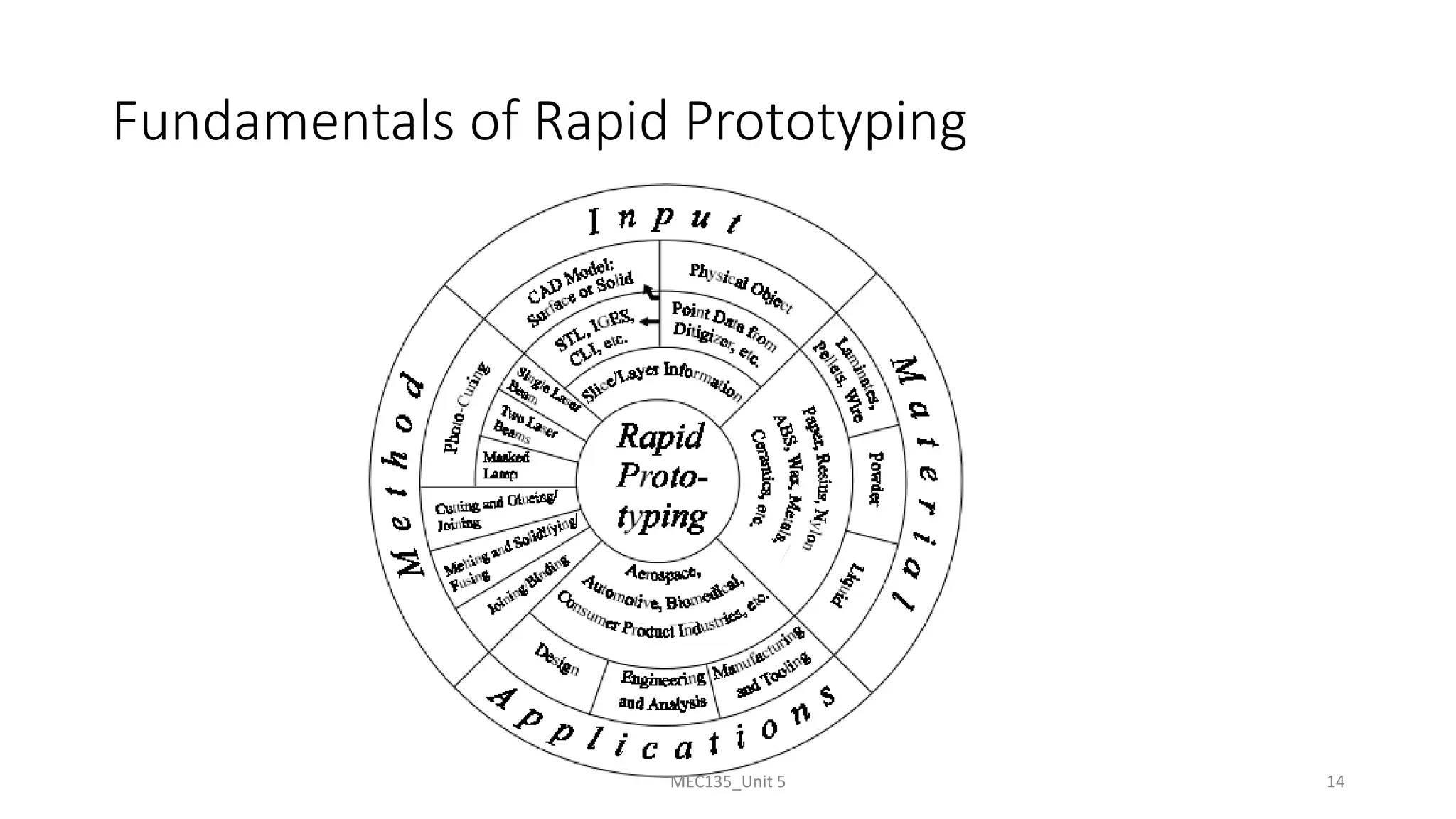

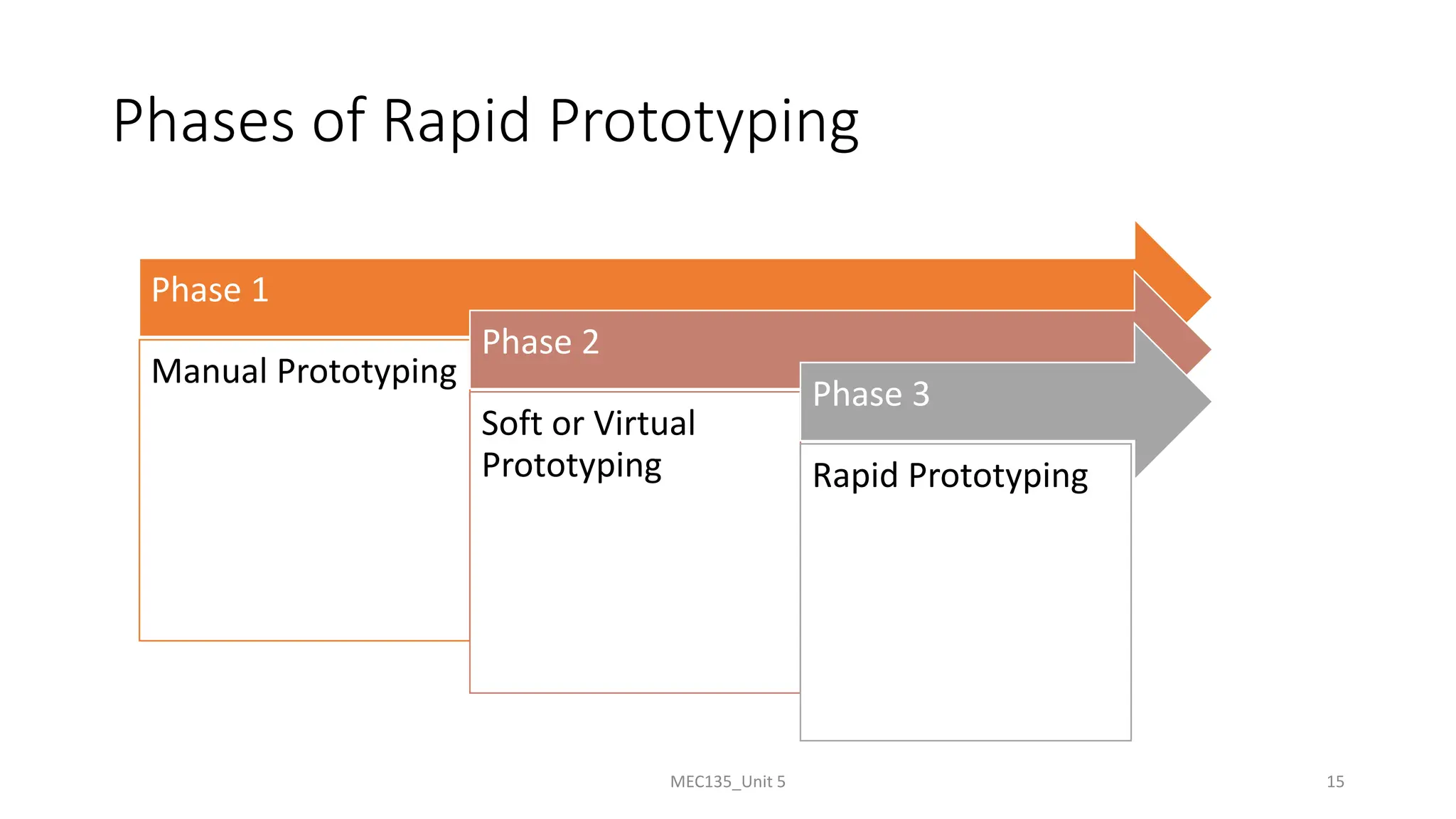

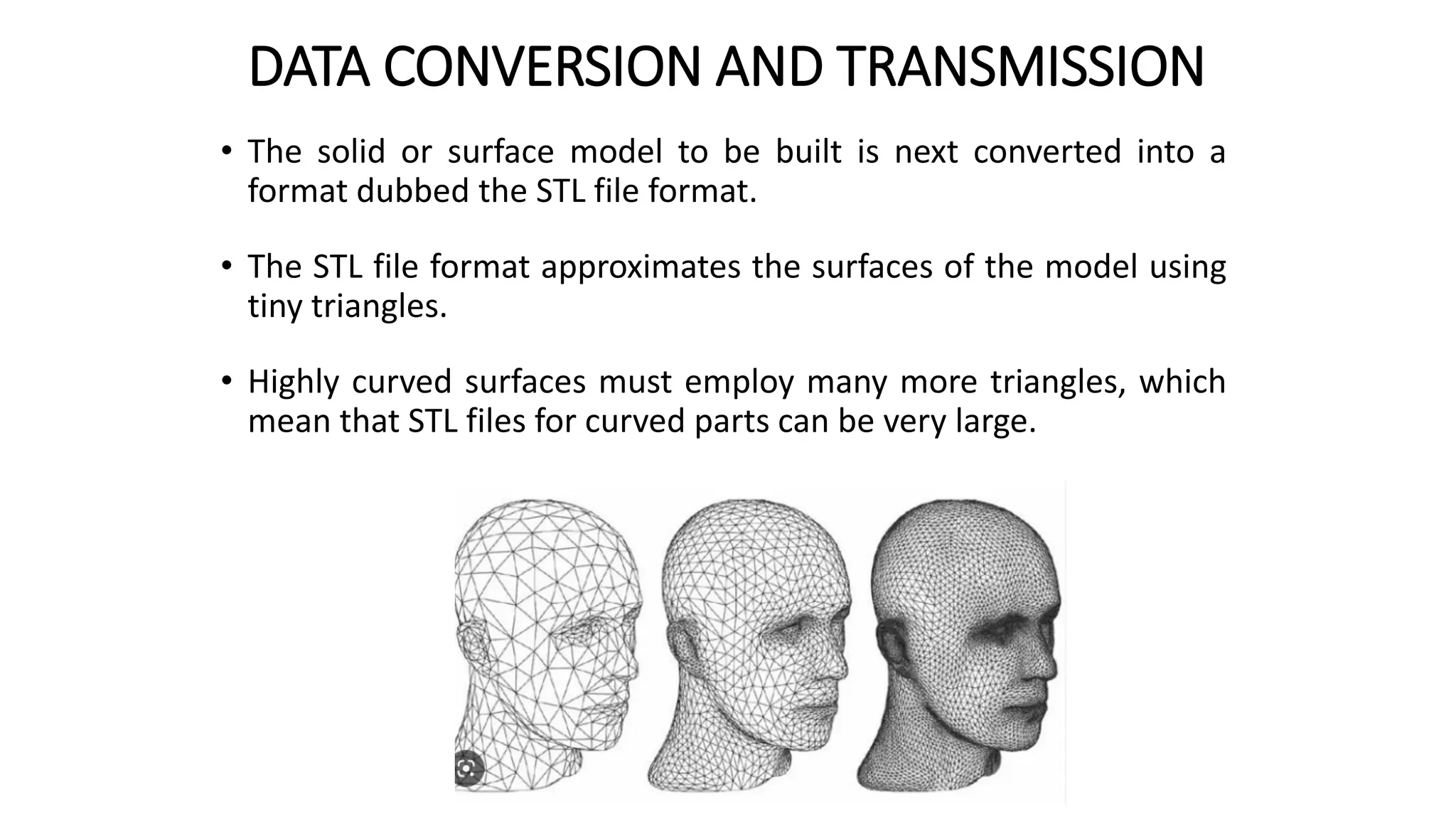

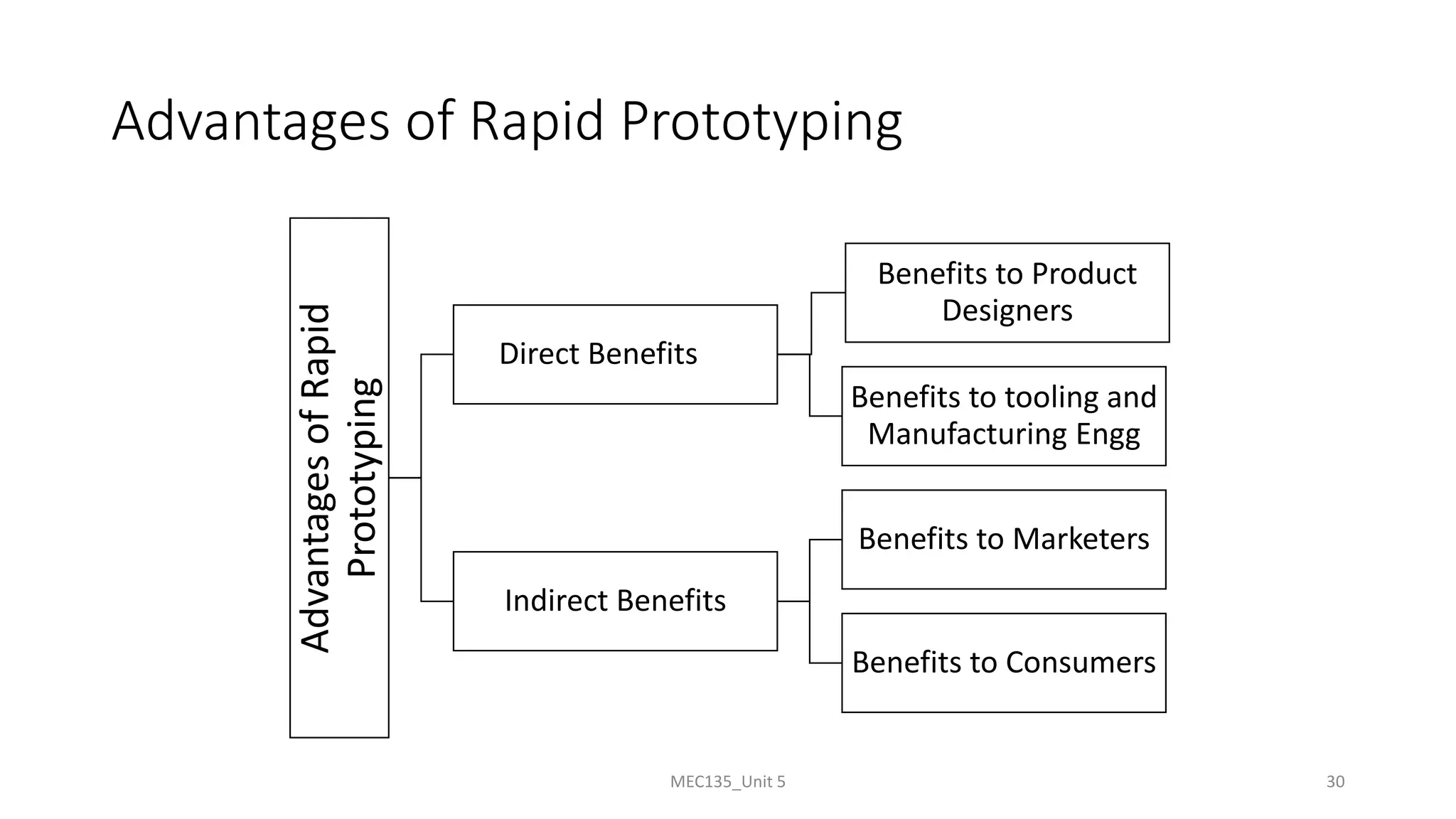

The document introduces digital fabrication, highlighting its significance in modern manufacturing processes, particularly through rapid prototyping. It outlines the fundamentals of rapid prototyping, including its phases, types, and advantages, emphasizing the efficiency and cost-effectiveness of producing prototypes in-house. Furthermore, it discusses the roles of prototypes in product development, aiding experimentation, testing, and communication among teams.