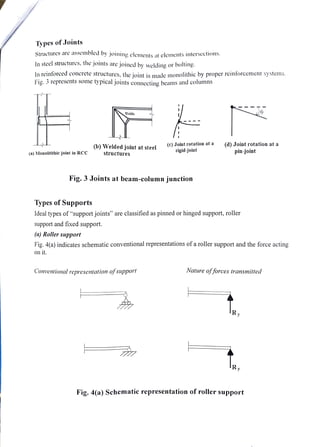

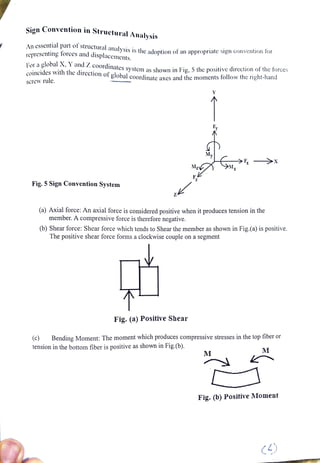

The document discusses advanced structural analysis, focusing on the definition and types of structures, such as beams, columns, and slabs, along with their behavior under various forces. It describes the assembly of structures through joints and supports, the principle of superposition, loading conditions, and material properties, including elastic and plastic behavior. Key concepts include equilibrium, different load types, and the essential properties of structural materials used in construction.