This chapter discusses key concepts in product and service design including:

1. The strategic importance of design and identifying reasons for redesign like market opportunities.

2. The main questions, sources of ideas, and considerations in design like legal issues, ethics, and sustainability.

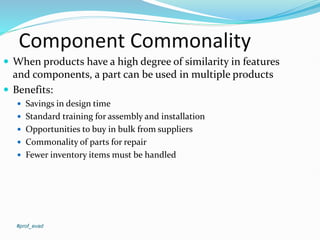

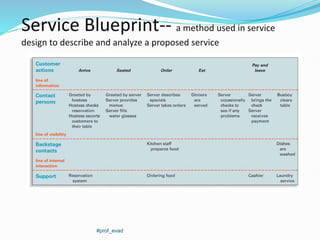

3. The phases of product design and key issues in manufacturing and service design.

4. Characteristics of well-designed service systems and challenges in service design.