Cembre S.p.A. is a certified manufacturer of electrical connectors and accessories based in Brescia, Italy, with a commitment to quality and environmental management. The company has achieved ISO 9001 certification for its quality management system and ISO 14001 for environmental management, as well as OHSAS 18001 for occupational health and safety. The catalogue outlines a wide range of standard products and emphasizes Cembre's focus on product quality and customer service.

![207

IEC 60228 : 2004 - 11 CONDUCTOR TABLES

MINIMUM AND MAXIMUM DIAMETERS OF STRANDED COMPACTED CIRCULAR COPPER, ALUMINIUM AND ALUMINIUM ALLOY CONDUCTORS

Cross-sectional area

[mm2

]

Stranded compacted circular conductors (Class 2)

Minimum diameter

[mm]

Maximum diameter

[mm]

10 3,6 4,0

16 4,6 5,2

25 5,6 6,5

35 6,6 7,5

50 7,7 8,6

70 9,3 10,2

95 11,0 12,0

120 12,3 13,5

150 13,7 15,0

185 15,3 16,8

240 17,6 19,2

300 19,7 21,6

400 22,3 24,6

500 25,3 27,6

630 28,7 32,5

NOTES: - The dimensional limits of Aluminium conductors with cross-sectional areas above 630 mm2

are not given as the compaction technology is not generally estabilished.2

are not given as the compaction technology is not generally estabilished.2

- The values are given for compacted Copper conductors in the size range 1,5 mm2

to 6 mm2

to 6 mm2 2

.

MAXIMUM DIAMETERS OF CIRCULAR COPPER CONDUCTORS: SOLID, NON COMPACTED STRANDED AND FLEXIBLE

Cross sectional area

[mm2

]

Conductors in cables for fixed installations

Flexible conductors (Classes 5 and 6)

Maximum diameter [mm]Solid (Class 1)

Maximum diameter [mm]

Stranded (Class 2)

Maximum diameter [mm]

0,5 0,9 1,1 1,1

0,75 1,0 1,2 1,3

1 1,2 1,4 1,5

1,5 1,5 1,7 1,8

2,5 1,9 2,2 2,4

4 2,4 2,7 3,0

6 2,9 3,3 3,9

10 3,7 4,2 5,1

16 4,6 5,3 6,3

25 a

5,7 6,6 7,8

35 a

6,7 7,9 9,2

50 a

7,8 9,1 11,0

70 a

9,4 11,0 13,1

95 a

11,0 12,9 15,1

120 a

12,4 14,5 17,0

150 a

13,8 16,2 19,0

185 15,4 18,0 21,0

240 17,6 20,6 24,0

300 19,8 23,1 27,0

400 22,2 26,1 31,0

500 - 29,2 35,0

630 - 33,2 39,0

800 - 37,6 -

1000 - 42,2 -

NOTE The values given for flexible conductors represent both class 5 and class 6 conductors.

a

Solid Copper conductor shaving cross-sectional areas of 25 mma

Solid Copper conductor shaving cross-sectional areas of 25 mma 2

and above are for particular types of cable, e.g. mineral insulated, and not for general purposes.2

and above are for particular types of cable, e.g. mineral insulated, and not for general purposes.2

MINIMUM AND MAXIMUM DIAMETERS OF CIRCULAR ALUMINIUM CONDUCTORS

Cross-sectional area

[mm2

]

Solid conductors (Class 1)

Minimum diameter

[mm]

Maximum diameter

[mm]

10 3,4 3,7

16 4,1 4,6

25 5,2 5,7

35 6,1 6,7

50 7,2 7,8

70 8,7 9,4

95 10,3 11,0

120 11,6 12,4

150 12,9 13,8

185 14,5 15,4

240 16,7 17,6

300 18,8 19,8

400 21,2 22,2

500 24,0 25,1

630 27,3 28,4

800 30,9 32,1

1000 34,8 36,0

1200 37,8 39,0](https://image.slidesharecdn.com/generalcatalogueltd13v029e-130617025158-phpapp01/85/Cembre-Hydraulic-Tools-Mechanical-Tools-Crimping-Tools-Cable-Cutters-ATEX-Cable-Glands-Cable-Clamps-Copper-Crimping-Lugs-HV-Copper-Terminals-Terminals-Connectors-207-320.jpg)

![208

IEC 60228 : 2004 - 11 CONDUCTOR TABLES

CLASS 1:

SOLID CONDUCTORS FOR SINGLE-CORE AND MULTI-CORE CABLES

Nominal cross-sectional

[mm2

]

Maximum resistance of conductor at 20 °C

Circular, annealed Copper conductors Aluminium and Aluminium alloy conductors,

circular or shaped c

[ohm/km]Plain [ohm/km] Metal [ohm/km]

0,5 36 36,7 -

0,75 24,5 24,8 -

1 18,1 18,2 -

1,5 12,1 12,2 -

2,5 7,41 7,56 -

4 4,61 4,70 -

6 3,08 3,11 -

10 1,83 1,84 3,08 a

16 1,15 1,16 1,91 a

25 0,727 b

- 1,20 a

35 0,524 b

- 0,868 a

50 0,387 b

- 0,641

70 0,268 b

- 0,443

95 0,193 b

- 0,320 d

120 0,153 b

- 0,253 d

150 0,124 b

- 0,206 d

185 0,101 b

- 0,164 d

240 0,0775 b

- 0,125 d

300 0,0620 b

- 0,100 d

400 0,0465 b

- 0,0778

500 - - 0,0605

630 - - 0,0469

800 - - 0,0367

1000 - - 0,0291

1200 - - 0,0247

aaa

Aluminium conductors 10 mm2

to 35 mm2

to 35 mm2 2

circular only2

circular only2

bbb

Solid Copper conductors having nominal cross-sectional area of 25 mm2

and above are for particular types of cable, e.g. mineral insulated, and not for general purposes.2

and above are for particular types of cable, e.g. mineral insulated, and not for general purposes.2

ccc

For solid Aluminium alloy conductors, having the same nominal cross-sectional area as an Aluminium conductor, the resistance value given in the table should be multiplied by a factor of

1,162 unless otherwise agreed between the manufacturer and the purchaser.

ddd

For single core cables, four sectoral shaped conductors may be assembled into a single circular conductor. The maximum resistance of the assembled conductor shall be 25% of that of the

individual component conductors.

CLASS 2:

STRANDED CONDUCTORS FOR SINGLE-CORE AND MULTI-CORE CABLES

Nominal cross-

sectional area

[mm2

]

Minimum number of wires in the conductor Maximum resistance of conductor at 20 °C

Circular Circular compacted Shaped Annealed copper conductor Aluminium or Aluminium

alloy conductor c

[ohm/

km]Cu Al Cu Al Cu Al Plain wires [ohm/km]

Metal-coated wires

[ohm/km]

0,5 7 - - - - - 36,0 36,7 -

0,75 7 - - - - - 24,5 24,8 -

1,0 7 - - - - - 18,1 18,2 -

1,5 7 - 6 - - - 12,1 12,2 -

2,5 7 - 6 - - - 7,41 7,56 -

4 7 - 6 - - - 4,61 4,70 -

6 7 - 6 - - - 3,08 3,11 -

10 7 7 6 6 - - 1,83 1,84 3,08

16 7 7 6 6 - - 1,15 1,16 1,91

25 7 7 6 6 6 6 0,727 0,734 1,20

35 7 7 6 6 6 6 0,524 0,529 0,868

50 19 19 6 6 6 6 0,387 0,391 0,641

70 19 19 12 12 12 12 0,268 0,270 0,443

95 19 19 15 15 15 15 0,193 0,195 0,320

120 37 37 18 15 18 15 0,153 0,154 0,253

150 37 37 18 15 18 15 0,124 0,126 0,206

185 37 37 30 30 30 30 0,0991 0,100 0,164

240 61 61 34 30 34 30 0,0754 0,0762 0,125

300 61 61 34 30 34 30 0,0601 0,0607 0,100

400 61 61 53 53 53 53 0,0470 0,0475 0,0778

500 61 61 53 53 53 53 0,0366 0,0369 0,0605

630 91 91 53 53 53 53 0,0283 0,0286 0,0469

800 91 91 53 53 - - 0,0221 0,0224 0,0367

1000 91 91 53 53 - - 0,0176 0,0177 0,0291

1200 b

b

b

b

b

b

0,0151 0,0151 0,0247

1400 a

0,0129 0,0129 0,0212

1600 0,0113 0,0113 0,0186

1800 a

0,0101 0,0101 0,0165

2000 0,0090 0,0090 0,0149

2500 0,0072 0,0072 0,0127

a

Non-preferred sizes. Other non-preferred sizes are recognized for some specialized applications but are not within the scope of this standard.a

Non-preferred sizes. Other non-preferred sizes are recognized for some specialized applications but are not within the scope of this standard.a

b

The minimum number of wires for these sizes is not specified. These sizes may be constructed from 4, 5 or 6 equal segments (Milliken).b

The minimum number of wires for these sizes is not specified. These sizes may be constructed from 4, 5 or 6 equal segments (Milliken).b

c

For stranded Aluminium alloy conductors having the same nominal cross-sectional area as an Aluminium conductor the resistance value should be agreed between the manufacturer and the purchaser.Aluminium conductor the resistance value should be agreed between the manufacturer and the purchaser.Aluminium](https://image.slidesharecdn.com/generalcatalogueltd13v029e-130617025158-phpapp01/85/Cembre-Hydraulic-Tools-Mechanical-Tools-Crimping-Tools-Cable-Cutters-ATEX-Cable-Glands-Cable-Clamps-Copper-Crimping-Lugs-HV-Copper-Terminals-Terminals-Connectors-208-320.jpg)

![209

IEC 60228 : 2004 - 11 CONDUCTOR TABLES

CLASS 5:

FLEXIBLE COPPER CONDUCTORS FOR SINGLE-CORE AND MULTI-CORE CABLES

Nominal cross-sectional

[mm2

]

Maximum diameter of wires in conductor

[mm]

Maximum resistance of conductor at 20 °C

Plain wires [ohm/km] Metal-coated wires [ohm/km]

0,5 0,21 39,0 40,1

0,75 0,21 26,0 26,7

1,0 0,21 19,5 20,0

1,5 0,26 13,3 13,7

2,5 0,26 7,98 8,21

4 0,31 4,95 5,09

6 0,31 3,30 3,39

10 0,41 1,91 1,95

16 0,41 1,21 1,24

25 0,41 0,780 0,795

35 0,41 0,554 0,565

50 0,41 0,386 0,393

70 0,51 0,272 0,277

95 0,51 0,206 0,210

120 0,51 0,161 0,164

150 0,51 0,129 0,132

185 0,51 0,106 0,108

240 0,51 0,0801 0,0817

300 0,51 0,0641 0,0654

400 0,51 0,0486 0,0495

500 0,61 0,0384 0,0391

630 0,61 0,0287 0,0292

CLASS 6:

FLEXIBLE COPPER CONDUCTORS FOR SINGLE-CORE AND MULTI-CORE CABLES

Nominal cross-sectional

[mm2

]

Maximum diameter of wires in conductor

[mm]

Maximum resistance of conductor at 20 °C

Plain wires [ohm/km] Metal-coated wires [ohm/km]

0,5 0,16 39,0 40,1

0,75 0,16 26,0 26,7

1.0 0,16 19,5 20,0

1,5 0,16 13,3 13,7

2,5 0,16 7,98 8,21

4 0,16 4,95 5,09

6 0,21 3,30 3,39

10 0,21 1,91 1,95

16 0,21 1,21 1,24

25 0,21 0,780 0,795

35 0,21 0,554 0,565

50 0,31 0,386 0,393

70 0,31 0,272 0,277

95 0,31 0,206 0,210

120 0,31 0,161 0,164

150 0,31 0,129 0,132

185 0,41 0,106 0,108

240 0,41 0,0801 0,0817

300 0,41 0,0641 0,0654](https://image.slidesharecdn.com/generalcatalogueltd13v029e-130617025158-phpapp01/85/Cembre-Hydraulic-Tools-Mechanical-Tools-Crimping-Tools-Cable-Cutters-ATEX-Cable-Glands-Cable-Clamps-Copper-Crimping-Lugs-HV-Copper-Terminals-Terminals-Connectors-209-320.jpg)

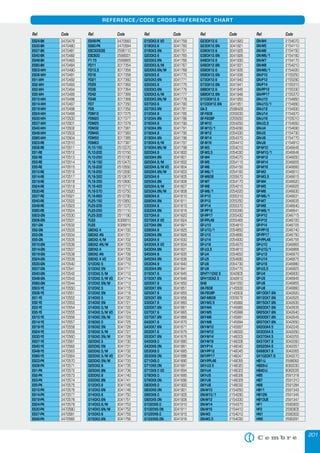

![211

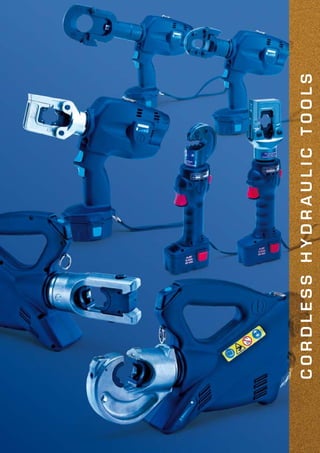

UL AND VDE MARKING OF CABLE GLANDS

VDE: Licence nos 40008472, 40008474, 40008475 and 40008476

USL-CNL: UL LISTING file no E220310; control no 48SB valid in USA & Canada

USR-CNR: UL RECOGNITION file no E220310 valid in USA & Canada (with reduced tightening force)

(*) EN 50262 § 9.4

-

Add to Ref: N for Black, G for Dark Grey

USR-CNR

USR-CNR

USR-CNR

USL-CNL

USL-CNL

USL-CNL

USL-CNL

USL-CNL

USL-CNL

USL-CNL

USR-CNR

USR-CNR

USL-CNL

USL-CNL

USL-CNL

USL-CNL

USL-CNL

USR-CNR

USR-CNR

USR-CNR

USL-CNL

USL-CNL

USL-CNL

USR-CNR

USR-CNR

USL-CNL

USL-CNL

USL-CNL

USR-CNR

USR-CNR

USL-CNL

USL-CNL

Pg 7

Pg 9

Pg 11

Pg 13,5

Pg 16

Pg 21

Pg 29

Pg 36

Pg 42

Pg 48

Pg 9

Pg 11

Pg 13,5

Pg 16

Pg 21

Pg 29

Pg 36

Pg 7

Pg 9

Pg 11

Pg 13,5

Pg 16

Pg 21

G1/4”

G3/8”

G1/2”

G3/4”

G1/2”

G1/4”

G3/8”

G1/2”

G3/4”

3,5-7

5-8

5-10

7-12

10-14

13-18

18-25

20-32

28-38

37-45

5-8

5-10

7-12

10-14

13-18

18-25

20-32

3,5-7

5-8

5-10

7-12

10-14

13-18

3-6,5

4-8

7-12

13-18

7-12

3-6,5

4-8

7-12

13-18

4.5-6.5

5.5-8

6.5-9.5

8-11.5

10.5-14

13-18

18.5-25

21.5-32

28-38

40-44

5.5-8

6.5-9.5

8-11.5

10.5-14

13-18

18.5-25

21.5-32

4.5-6.5

5.5-8

6.5-9.5

8-11.5

10.5-14

13-18

4.5-6.5

5.5-8

8-11.5

13-18

8-11.5

4.5-6.5

5.5-8

8-11.5

13-18

0.18-0.25

0.22-0.31

0.26-0.37

0.31-0.45

0.41-0.55

0.51-0.71

0.73-0.98

0.85-1.26

1.10-1.49

1.57-1.73

0.22-0.31

0.26-0.37

0.31-0.45

0.41-0.55

0.51-0.71

0.73-0.98

0.85-1.26

0.18-0.25

0.22-0.31

0.26-0.37

0.31-0.45

0.41-0.55

0.51-0.71

0.18-0.25

0.22-0.31

0.31-0.45

0.51-0.71

0.31-0.45

0.18-0.25

0.22-0.31

0.31-0.45

0.51-0.71

1900.07

1900.09

1900.11

1900.13

1900.16

1900.21

1900.29

1900.36

1900.42

1900.48

1901.09

1901.11

1901.13

1901.16

1901.21

1901.29

1901.36

1500.07

1500.09

1500.11

1500.13

1500.16

1500.21

1900.14

1900.38

1900.12

1900.34

1901.12

1500.14

1500.38

1500.12

1500.34

COMPRESSION RANGE

Ø min-maxRef.

Light

Grey

Thread

UL 514B

[mm] [inches]

MARKING

Nominal

[mm]

Ref.

Nickel

Plated

Brass

Thread MARKING

M12x1,5

M16x1,5

M20x1,5

M25x1,5

M32x1,5

M40x1,5

M50x1,5

M63x1,5

M12x1,5

M16x1,5

M20x1,5

M25x1,5

M32x1,5

M40x1,5

M50x1,5

M63x1,5

M12x1,5

M16x1,5

M20x1,5

M25x1,5

M32x1,5

M40x1,5

M50x1,5

M12x1,5

M16x1,5

M20x1,5

M25x1,5

M32x1,5

M40x1,5

M50x1,5

3-7

4,5-10

7-13

10-17

11-21

19-28

26-35

34-45

1-5

2,5-7

5-10

6-13

7-14

13-23

20-29

27-39

3-7

4,5-10

7-13

10-17

11-21

19-28

26-35

1-5

2,5-7

5-10

6-13

7-14

13-23

20-29

3-7

4,5-10

8-13

10-17

11-21

19-28

27-35

34-45

2-5

3,5-7

5-10

6-13

7-14

15-23

20-29

28-39

3-7

4,5-10

8-13

10-17

11-21

19-28

27-35

2-5

3,5-7

5-10

6-13

7-14

15-23

20-29

0.12-0.28

0.18-0.39

0.31-0.51

0.39-0.67

0.43-0.83

0.75-1.10

1.06-1.38

1.33-1.77

0.08-0.20

0.14-0.28

0.20-0.39

0.24-0.51

0.28-0.55

0.59-0.90

0.79-1.14

1.10-1.54

0.12-0.28

0.18-0.39

0.31-0.51

0.39-0.67

0.43-0.83

0.75-1.10

1.06-1.38

0.08-0.20

0.14-0.28

0.20-0.39

0.24-0.51

0.28-0.55

0.59-0.90

0.79-1.14

3-7

4,5-10

7-13

10-17

11-21

19-28

26-35

34-45

1-5

2,5-7

5-10

6-13

7-14

17-23

22-29

31-39

3-7

4,5-10

7-13

10-17

11-21

19-28

26-35

1-5

2,5-7

5-10

6-13

7-14

13-23

22-29

USR-CNR / VDE

USL-CNL / VDE

USL-CNL / VDE

USL-CNL / VDE

USL-CNL / VDE

USL-CNL / VDE

USL-CNL / VDE

USL-CNL / VDE

USR-CNR / VDE

USR-CNR / VDE

USR-CNR / VDE

USR-CNR / VDE

USR-CNR / VDE

USL-CNL / VDE

USL-CNL / VDE

USL-CNL / VDE

USR-CNR/VDE

USL-CNL / VDE

USL-CNL / VDE

USL-CNL / VDE

USL-CNL / VDE

USL-CNL / VDE

USL-CNL / VDE

USR-CNR/VDE

USR-CNR / VDE

USR-CNR / VDE

USR-CNR / VDE

USR-CNR/VDE

USL-CNL / VDE

USL-CNL / VDE

2900.M12N

2900.M16N

2900.M20N

2900.M25N

2900.M32N

2900.M40N

2900.M50N

2900.M63N

2910.M12N

2910.M16N

2910.M20N

2910.M25N

2910.M32N

2910.M40N

2910.M50N

2910.M63N

2901.M12N

2901.M16N

2901.M20N

2901.M25N

2901.M32N

2901.M40N

2901.M50N

2911.M12N

2911.M16N

2911.M20N

2911.M25N

2911.M32N

2911.M40N

2911.M50N

EN 50262

[mm]

UL 514B

[mm] [inches]

Nominal

[mm]

COMPRESSION RANGE

Ø min-max IMPACT

CATEGORY

(*)

5

6

6

6

6

6

6

6

5

6

6

6

6

6

6

6

5

6

6

6

6

6

6

5

6

6

6

6

6

6

-

USR-CNR / VDE

USR-CNR / VDE

USL-CNL / VDE

USL-CNL / VDE

USL-CNL / VDE

USL-CNL / VDE

USL-CNL / VDE

USL-CNL / VDE

USR-CNR / VDE

USR-CNR / VDE

USR-CNR / VDE

USR-CNR / VDE

USR-CNR / VDE

USL-CNL / VDE

USL-CNL / VDE

USL-CNL / VDE

USR-CNR / VDE

USR-CNR / VDE

USL-CNL / VDE

USL-CNL / VDE

USL-CNL / VDE

USL-CNL / VDE

USL-CNL / VDE

USL-CNL / VDE

USR-CNR / VDE

USR-CNR / VDE

USL-CNL / VDE

USL-CNL / VDE

USL-CNL / VDE

USL-CNL

USL-CNL

M12x1,5

M16x1,5

M20x1,5

M25x1,5

M32x1,5

M40x1,5

M50x1,5

M63x1,5

M12x1,5

M16x1,5

M20x1,5

M25x1,5

M32x1,5

M40x1,5

M50x1,5

M63x1,5

M12x1,5

M16x1,5

M20x1,5

M25x1,5

M32x1,5

M40x1,5

M50x1,5

M63x1,5

M12x1,5

M16x1,5

M20x1,5

M25x1,5

M32x1,5

M25x1,5

M25x1,5

3,5-7

5-10

7-13

10-17

13-21

19-28

27-35

34-45

2-5

3-7

5-10

7-13

8-14

15-23

21-29

27-39

3,5-7

5-10

7-13

10-17

13-21

19-28

27-35

34-45

3,5-7

5-10

7-13

10-17

13-21

13-18

13-18

3,5

7

13

17

15-21

21-28

27-34

35-45

2-5

4-7

5-10

7-13

8-14

15-23

21-29

28-39

3,5

7

13

17

15-21

21-28

27-34

35-45

3,5

7

13

17

15-21

13-18

13-18

0.14

0.28

0.51

0.67

0.60-0.83

0.83-1.10

1.06-1.34

1.38-1.77

0.08-0.20

0.16-0.28

0.20-0.40

0.28-0.51

0.31-0.55

0.59-0.91

0.83-1.14

1.1-1.54

0.14

0.28

0.51

0.67

0.60-0.83

0.83-1.10

1.06-1.34

1.38-1.77

0.14

0.28

0.51

0.67

0.60-0.83

0.51-0.71

0.51-0.71

3,5-7

7-10

7-13

10-17

13-21

19-28

27-35

34-45

2-5

4-7

5-10

7-13

8-14

15-23

21-29

27-39

3,5-7

7-10

7-13

10-17

13-21

19-28

27-35

34-45

3,5-7

7-10

7-13

10-17

13-21

-

-

1900.M12

1900.M16

1900.M20

1900.M25

1900.M32

1900.M40

1900.M50

1900.M63

1910.M12

1910.M16

1910.M20

1910.M25

1910.M32

1910.M40

1910.M50

1910.M63

1901.M12

1901.M16

1901.M20

1901.M25

1901.M32

1901.M40

1901.M50

1901.M63

1500.M12

1500.M16

1500.M20

1500.M25

1500.M32

1940.M25

1540.M25

COMPRESSION RANGE

Ø min-maxRef.

Light

Grey

Thread

UL 514B

[mm] [inches]

EN 50262

[mm]

MARKING

Nominal

[mm]

IMPACT

CATEGORY

(*)

1

1

3

3

3

3

3

3

1

1

3

3

3

3

3

3

1

1

3

3

3

3

3

3

1

1

3

3

3

-

-

Add to Ref: N for Black, G for Dark Grey

Ref.

Nickel

Plated

Brass

Thread MARKING

Pg 7

Pg 9

Pg 11

Pg 13,5

Pg 16

Pg 21

Pg 29

Pg 36

Pg 42

Pg 48

Pg 7

Pg 9

Pg 11

Pg13,5

Pg 16

Pg 21

Pg 29

Pg 36

Pg 42

Pg 48

Pg 7

Pg 9

Pg 11

Pg13,5

Pg 16

Pg 21

Pg 29

Pg 36

Pg 42

Pg 7

Pg 9

Pg 11

Pg13,5

Pg 16

Pg 21

Pg29

Pg36

Pg42

3-7

4-8

4,5-10

5-12

7-13

10-17

17-25

20-32

28-38

34-45

1-5

2-6

2,5-7

4-10

5-10

6-13

11-20

18-26

24-31

27-39

3-7

4-8

4,5-10

5-12

7-13

10-17

17-25

20-32

28-38

1-5

2-6

2,5-7

4-10

5-10

6-13

11-20

18-26

24-31

3-7

4-8

4,5-10

9-12

10-13

12-17

18-25

22-32

28-35

34-45

1-5

3-6

3,5-7

5,5-10

6-10

7-13

12-20

19-26

24-31

31-39

3-7

4-8

4,5-10

9-12

10-13

12-17

18-25

22-32

28-35

1-5

3-8

3,5-7

5,5-10

6-10

7-13

12-20

19-26

24-31

0.12-0.28

0.16-0.31

0.18-0.39

0.35-0.47

0.39-0.51

0.47-0.67

0.71-0.98

0.86-1.26

1.10-1.38

1.33-1.77

0.04-0.20

0.12-0.24

0.14-0.28

0.22-0.39

0.24-0.39

0.28-0.51

0.47-0.79

0.75-1.02

0.94-1.22

1.22-1.54

0.12-0.28

0.16-0.31

0.18-0.39

0.35-0.47

0.39-0.51

0.47-0.67

0.71-0.98

0.86-1.26

1.10-1.38

0.04-0.20

0.12-0.31

0.14-0.28

0.22-0.39

0.24-0.39

0.28-0.51

0.47-0.79

0.75-1.02

0.94-1.22

USR-CNR

USR-CNR

USR-CNR

USL-CNL

USL-CNL

USL-CNL

USL-CNL

USL-CNL

USL-CNL

USL-CNL

USR-CNR

USR-CNR

USR-CNR

USR-CNR

USR-CNR

USR-CNR

USR-CNR

USL-CNL

USL-CNL

USL-CNL

USR-CNR

USR-CNR

USR-CNR

USL-CNL

USL-CNL

USL-CNL

USL-CNL

USL-CNL

USL-CNL

USR-CNR

USR-CNR

USR-CNR

USR-CNR

USR-CNR

USR-CNR

USR-CNR

USL-CNL

USL-CNL

2900.07N

2900.09N

2900.11N

2900.13N

2900.16N

2900.21N

2900.29N

2900.36N

2900.42N

2900.48N

2910.07N

2910.09N

2910.11N

2910.13N

2910.16N

2910.21N

2910.29N

2910.36N

2910.42N

2910.48N

2901.07N

2901.09N

2901.11N

2901.13N

2901.16N

2901.21N

2901.29N

2901.36N

2901.42N

2911.07N

2911.09N

2911.11N

2911.13N

2911.16N

2911.21N

2911.29N

2911.36N

2911.42N

UL 514B

[mm] [inches]

Nominal

[mm]

COMPRESSION RANGE

Ø min-max](https://image.slidesharecdn.com/generalcatalogueltd13v029e-130617025158-phpapp01/85/Cembre-Hydraulic-Tools-Mechanical-Tools-Crimping-Tools-Cable-Cutters-ATEX-Cable-Glands-Cable-Clamps-Copper-Crimping-Lugs-HV-Copper-Terminals-Terminals-Connectors-211-320.jpg)