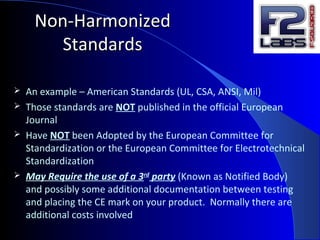

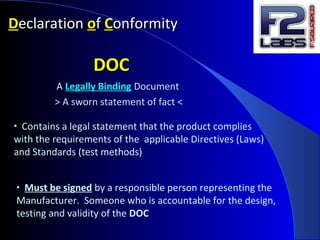

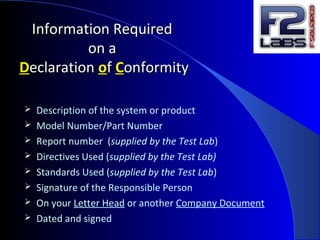

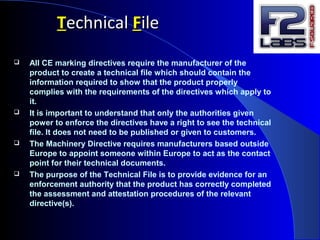

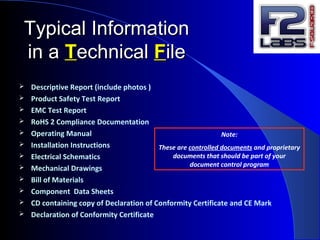

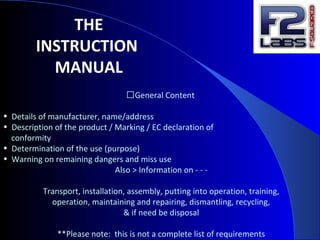

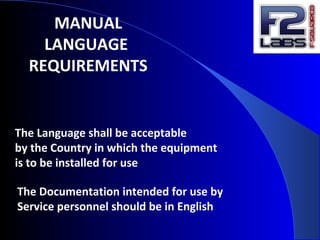

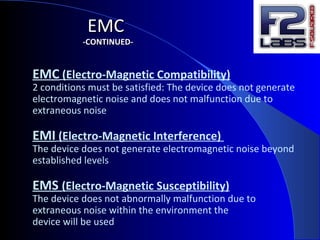

The document provides an overview of CE marking and the compliance requirements for products entering the European Union, emphasizing the need for safety and EMC testing. It discusses the roles of different standards and organizations involved in the certification process and outlines the necessary documentation, such as the declaration of conformity and technical files. Additionally, the document highlights the consequences of non-compliance, including legal penalties and market restrictions.