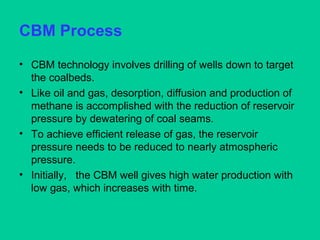

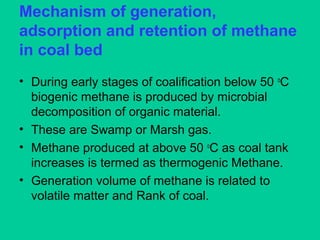

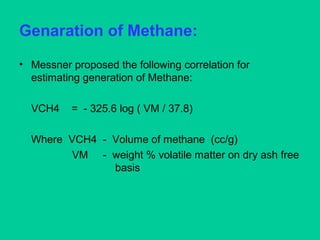

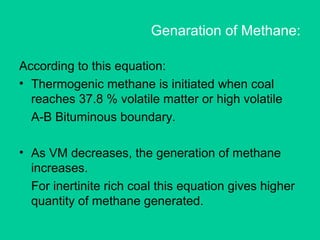

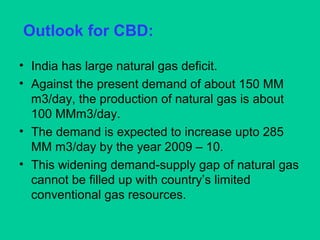

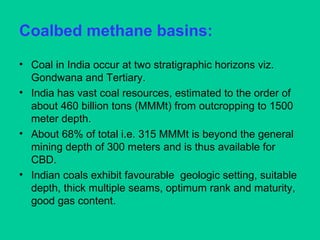

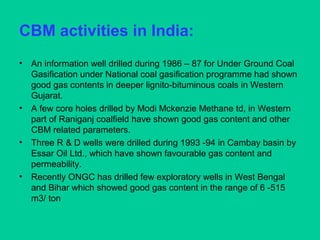

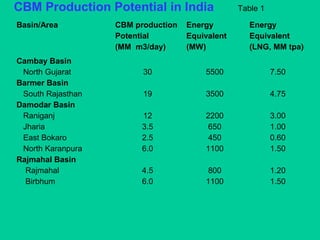

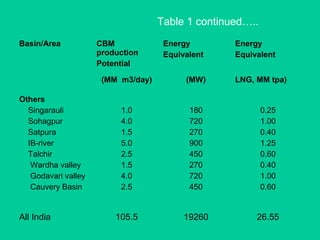

Coalbed methane exists naturally within coal deposits and can be extracted through drilling wells. As coal is buried deeper underground over time, microbial and thermal processes generate methane that gets stored in the coal. Technology has been developed to safely extract this methane by reducing reservoir pressure and allowing the gas to desorb from the coal. The United States has successfully commercialized coalbed methane extraction through thousands of wells. India also has significant coalbed methane potential across its major coal basins, with initial exploration showing good gas contents. Commercial development of this resource could help meet India's growing natural gas demand and improve energy security.